- Joined

- Nov 16, 2009

- Messages

- 4,539

- Reaction score

- 8,061

Trying to warn folks who hunt in PA's flint season not to bother with a used TC piece o manure.

Trying to warn folks who hunt in PA's flint season not to bother with a used TC piece o manure.

Here is 1 of my TC Hawken Stocks with a 1:24 Twist Rice .50 Cal Barrel at 1,200 Yards, This is a LONG Poke

I wasnt even talking about globe site but I have easily filed down the base of the dovetail and filed a new dovetail@SPQR70AD, curious how you file down the 17 ATC (sight on the left) to the height of 17 AHB (sight on the right mounted on the barrel)? View attachment 94348

For setting up a TC with a Lyman 57 SML, I recommend the 17 AHB, the lowest or shortest Lyman in the 17 series of globe sights, about .404” from the bottom of the dovetail to the center of the sight. If you go with a higher front sight you will have to mount the rear sight quite high off the barrel. The 45 caliber TCs I have setup like this can go to 500 plus yards, but I typically only shoot them to 300 or so. Again, you CAN NOT file the Lyman 17 Globe Sight down, so DO NOT start with highest one.

you can file the base easily and recut the dovetail. I have done it and I am a caveman with hand tools. I also made a dovetail out of a small block of steel for another rifle@SPQR70AD, curious how you file down the 17 ATC (sight on the left) to the height of 17 AHB (sight on the right mounted on the barrel)? View attachment 94348

For setting up a TC with a Lyman 57 SML, I recommend the 17 AHB, the lowest or shortest Lyman in the 17 series of globe sights, about .404” from the bottom of the dovetail to the center of the sight. If you go with a higher front sight you will have to mount the rear sight quite high off the barrel. The 45 caliber TCs I have setup like this can go to 500 plus yards, but I typically only shoot them to 300 or so. Again, you CAN NOT file the Lyman 17 Globe Sight down, so DO NOT start with highest one.

I wasnt even talking about globe site but I have easily filed down the base of the dovetail and filed a new dovetail

you can file the base easily and recut the dovetail. I have done it and I am a caveman with hand tools. I also made a dovetail out of a small block of steel for another rifle. you would be stunned when taking off just a little makes a huge difference on where the shot falls. at long range it is amplified.

One of the ranges I attend has a life-size mountain goat target out abou 400 yd. When we have m/l matches there, most of us take a couple of cracks at it. On dry days, when I can see the shotfall, I usually manage to hit it about 1 in 5. I usually pick an aiming point about 5 target heights above to start, and adjust when I see the dust. I got lucky one time, and hit it with the first shot (Said 'That's how it's done." Grabbed my stuff and went back to camp.)If there was one thing I would like to see, I would love to see a shot made off hand.

The rifle is clearly capable and if I were there I would be asking for a crack at it

now that is an honest assessment of shooting long range offhand. thanks for that postOne of the ranges I attend has a life-size mountain goat target out abou 400 yd. When we have m/l matches there, most of us take a couple of cracks at it. On dry days, when I can see the shotfall, I usually manage to hit it about 1 in 5. I usually pick an aiming point about 5 target heights above to start, and adjust when I see the dust. I got lucky one time, and hit it with the first shot (Said 'That's how it's done." Grabbed my stuff and went back to camp.)

best post of whole thread.............

And… I‘ll bet it bugs the manure out of him!Idaholewis,

Are your clover leafs always so, you know, irregular?

About the QLA thing, it's a great excuse to have a barrel relined.

@SDSmlf I guess it can be done that way. I wouldn’t start with the ATC…I wasnt even talking about globe site but I have easily filed down the base of the dovetail and filed a new dovetail

you can file the base easily and recut the dovetail. I have done it and I am a caveman with hand tools. I also made a dovetail out of a small block of steel for another rifle

Sure would look goofy with a short dovetail if you cut it down in my opinion. It was my mistake that when SPQR70AD responded to and quoted a post that specifically asked about the four different heights of the #17 front sights, he was talking about #17 globe sights, when apparently he wasn’t. I have to get better at knowing what people mean instead of taking literally what they post…. I just didn’t want Dude to order the tallest #17 sight and think it was easy to file it down.@SDSmlf I guess it can be done that way. I wouldn’t start with the ATC…

Trying to warn folks who hunt in PA's flint season not to bother with a used TC piece o manure.

[/QUOTE

Seems like the general consensus puts your opinion in the extreme minority. My guess is most people will just ignore it.Trying to warn folks who hunt in PA's flint season not to bother with a used TC piece o manure.

That"s why every one here has to replace the TC frizzens with Lyman or just gets am L&R replacement lock. and why TC's warranty is no longer any good. "Their GGGRREEAAT!!!" LOLSeems like the general consensus puts your opinion in the extreme minority. My guess is most people will just ignore it.

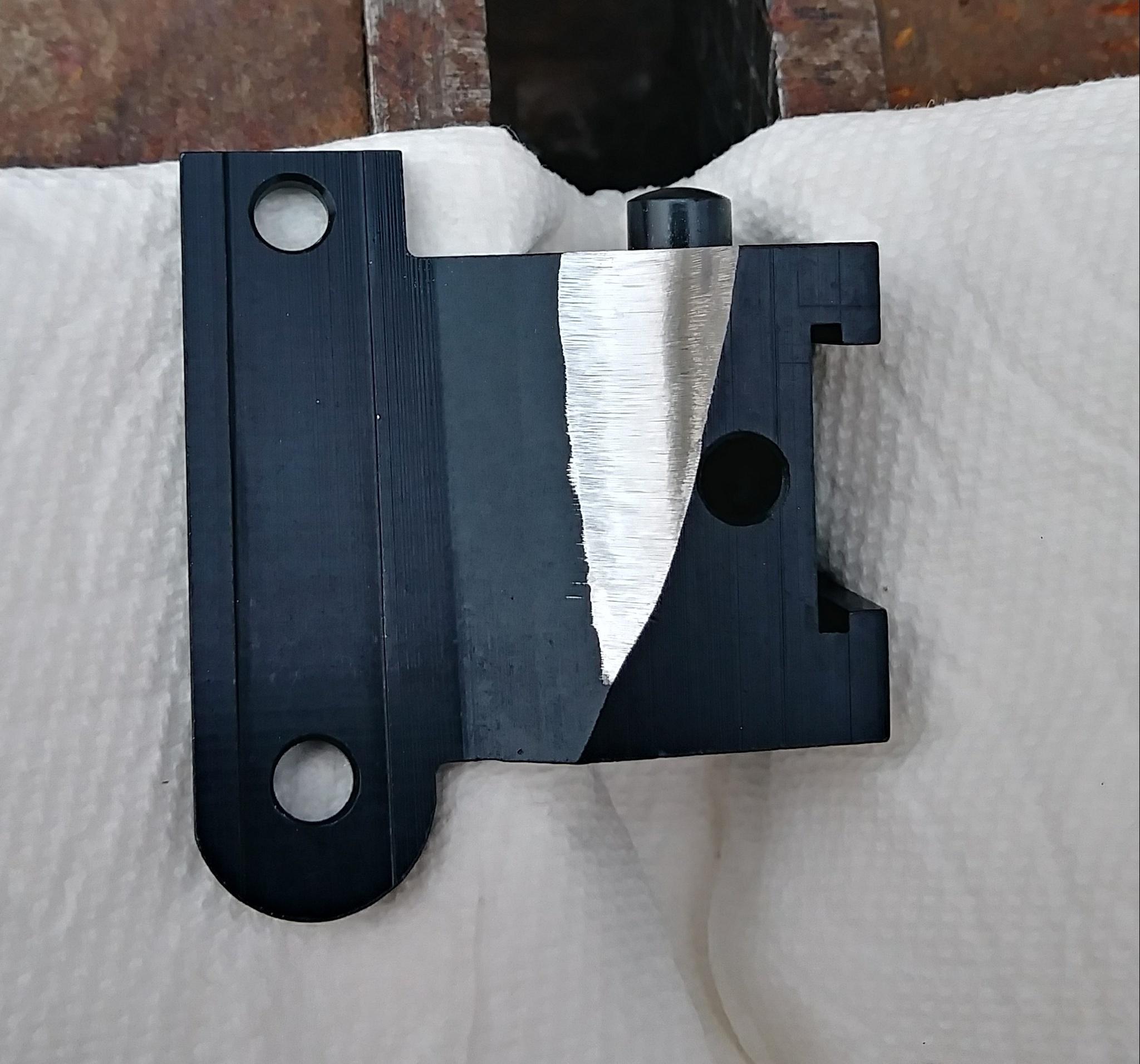

There is some Modification required, it is a simple task, i have done MANY of them. This is what you need to do to the 57SML Base, i do this with a Dremel Tool and a Course sanding Wheel, just takes a minute to do

And if your Tang is not drilled & tapped (some where, some weren’t) it will need to be, Drill & Tap to 8-32

It is an easy, straight forward process. First thing, is the Tang on your Rifle Drilled and Tapped for a Peep? TC Made some of Both, Some Tangs came Tapped for a Peep from the Factory, and Some Did not, out of my MANY Renegades and Hawkens only 1 of mine was Factory Drilled and Tapped, all of my others Required me to do it.

Not Drilled and Tapped for Peep. If your Tang is like this one you will need to Drill and Tap it to 8-32

Factory Drilled and Tapped for Peep, they added a Plug to protect the Threads.

The Lyman 57 Base will need to be Modified so that it Clears the Forward Wrist Wood of the Renegade.

It will look like this when you are done with it, i use a Dremel with a Sanding Wheel, takes about 2 minutes to do this. You can paint this black, or ignore it, it is Aluminum therefore will not Rust and this is Hidden as you will see below

Here you can See how it Clears the Forward Wrist Wood of this Renegade.

This is a FUZZY Picture of a Lyman 57 on 1 of my Hawkens, i did not have to do the Above sight base Mod on this Rifle, it Cleared after i added the Required Front Washers to take out the “Forward Tilt” here you can see the Corner that needs to be Removed from the Sight Base for Renegade installation. The Hawkens are a Bit thinner Through the Wrist of the Stock than the Renegades, Some Hawkens do not need the Sight Base Mod, But so far all Renegades i have worked with do, The Forward Wrist Wood of the Renegade’s are a Bit Thicker.

See the Corner on the underside of the 57 Sight Base i am Talking about here? Look between this pic and the 1 above

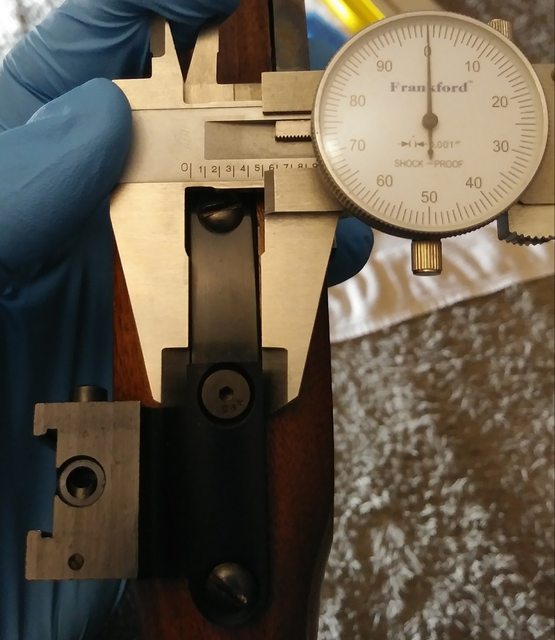

Drilling and tapping for Peep sight, How to find Dead Center of Tang

This is for education purposes only, You would be doing this with the Tang out of your Rifle of Course! This is just to Show you how to EASILY find Center of the Tang.

First, Measure the width of the Tang, all of the TC’s i have done Measure .500 across, Measure and make sure.

Now that we know the Tang is .500 Across, half of that is .250, Adjust calipers to .250 and Lock them down. With my Stainless calipers i can lightly Scribe a line here. Even if your Tang Measures Slightly Different than .500 just Take whatever the Full width measurement is and Cut that in Half

Now Flip the Calipers over and check from the other side, you will note the Lightly scribed line will match perfectly from this side :lewis: This is DEAD CENTER of your Tang.

All that’s left to do now is place the Lyman 57 on the Tang, use the Rear Tang Screw Through the 57 Base, This will Hold it FIRMLY in place, use a pencil and Mark the Front sight Base hole. Now Drill and Tap to 8-32, You can buy this Bit and Tap in a Kit, this is mine

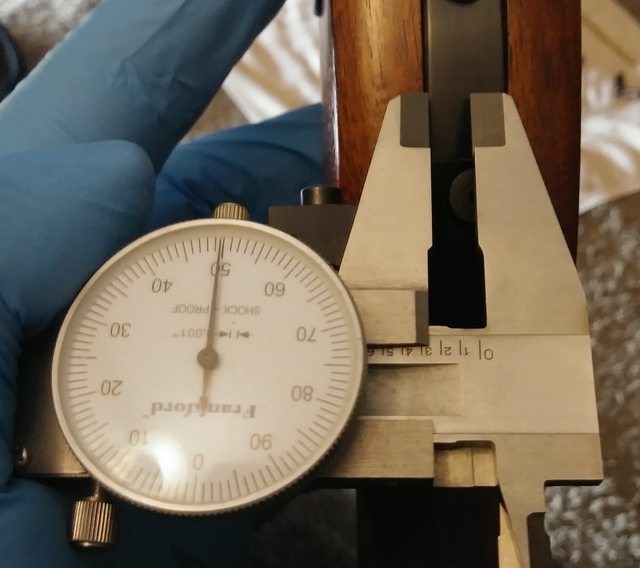

And lastly, Taking the Tilt/Forward lean out of the Lyman 57

First, Push the Button, pull the Slider out and set it aside. The Lyman 57 has a Nice Flat Top surface, use this to your advantage

The Lyman 57 Has a Tendency to Lean Forward, Lay a flat edge on the Top of the Lyman 57’s Flat Base and you will find that it Leans/tilts forward, Like this

Here is How I correct Lean/Tilt (All of my Rifles are like this) I use Stainless Washers that are the Width of the Tang, and the 8-32 Screw will just fit through the Washer hole. On average, I ad 1 washer under the Rear of the Sight Base, and how ever many i need up Front to Correct the Forward Lean, This varies from Rifle to Rifle, You simply need to play around here and get the Base as Close as you possibly can, Being off a tiny bit one way or the other is Fine, all we are doing here is correcting the LARGEST of it.

Here is what i am Looking for, when i place a Straight edge on the top Flat surface of the Lyman 57 Base i want the Straight edge to Run as Close as possible to Straight in line with my Stock/Barrel, Like this

Might as well Strike while the Iron is Hot

How to install a Lyman 17 series Globe front Sight (Or Any Front Sight For that matter)

Things needed, Padded Vise, A Brass Drift Punch, and a 3 corner file with a “Safe Side” Both of these can be made at Home. A Modified Brass Bolt works fine, or better yet a piece of Round Stock brass about 3-4 inches long. The Brass Drift punch is so you Don’t damage the Barrel, Sight

It is VERY Likely your new 17 Globe Front sight will be to tight to fit your Dovetail, All of the Lyman 17 Globes i have done so far have been Tight, To tight, They needed Fitting to my Dovetail, Lyman makes them a little on the Large side so they can be fitted, 99.9% of Stock US Barrel Dovetails with be 3/8” (.375) The Lyman 17 Globes i have measured come in closer to .380

You can spend the BIG BUCKS and Buy an actual Gun Smithing Dovetail file like these, They have a “Safe Side” 1 of the 3 Flats is Smooth, this allows the file to slide back n forth in your Dovetail (Safe side down) and not cut, You are ONLY Cutting, enlarging the Dove Angle.

BROWNELLS 60° DOVETAIL STANDARD SLOT SIGHT BASE FILES | Brownells

Or you could get a Small 3 Corner file at your local Hardware like i chose to do, i ground 1 Cutting edge off Square on a Hard Bench mounted Belt Sander to make a “Safe Side” (mine is a Nicholson, AWESOME files :lewis

This is Somewhat of a Tedious process, GO SLOW and CHECK OFTEN!

If you only need a few Thou removed to fit, you can take it off the Bottom of the Sight Dove itself, I don’t recommend doing this if it’s Anymore than a few Thou, Any more than that and you need to Either Take material Away from the Front sight Dovetail (make it smaller) or Open the Barrel Dovetail (make it bigger) i have done both, i prefer slightly enlarging the Barrel Dovetail, I place the Barrel in a Padded Vise and Snug it up to do this.

On the other Hand, if your Front sight fits to loose in the Barrel Dovetail, If it is just loose enough that you don’t fully trust it from possibly moving, Use some Red Loctite! That will HOLD IT LIKE A ROCK, yet you can stil Drift it out. But if the Front sight is Quite loose, You will need to Build the Bottom of the Sight Dovetail up with Shim stock until you get it Tight.

NONE of this stuff is hard to do, grab the Bull by the Horns and do it! Quit Paying a Gunsmith to do these SIMPLE things!

Trying to warn folks who hunt in PA's flint season not to bother with a used TC piece o manure.

You’re challenging shooting 1200 yards with a muzzle loader?I call complete Bull on a 1200 yard shot.

Here is 50cal round ball data. Your slug obviously has a better BC. Post up your Data.

Enter your email address to join: