- Joined

- Mar 7, 2007

- Messages

- 686

- Reaction score

- 2,095

A few months ago, a fellow by the name of Richard Newman got in contact with me via the Contemporary Makers site asked me if I could finish a little rifle he had started quite some time ago for his daughters. Â Time, business, and life had stopped progress and he was looking for someone to finish it for him. Â We met in June and I took over the project but warned him that I was in the midst of a large propulsion testing contract and would not be able to dedicate full time to the project. Â He told me the rifle had languished for several years, so any progress would be to the good.

Personally, I had also started a matched set of 1/2 scale rifles for my two daughters many, many years ago that I have never finished. Â And, in the natural order of things, the girls had not waited on me and are now both grown women. Â So, secondarily, I wanted to do this for Richard to make up for my own missed opportunity.

At any rate, I have been working on it a little at a time, and asked Richard if I could post the work here as it might be of interest to this community. Â He said to go ahead, so here goes.

It is always a bit of an issue to take over someone else's project, as you are never quite sure what the original vision was. Â Also, half way through a build, there are things that have been done that cannot be undone, without completely starting over, and must just be lived with. Â Luckily, Richard had done a great job up to the point he had to stop and turned the work over to me.

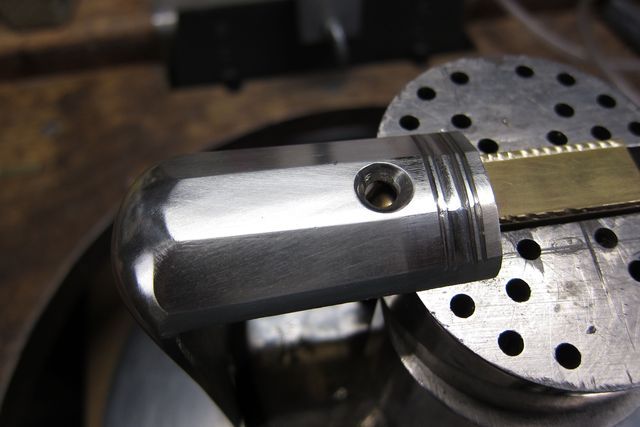

The rifle is 3/4 scale, suited for a child but easily handled by an adult. Â I was immediately taken with the size and style. Â It is a handy little rifle with an octagonal to round .45 caliber barrel. Â The lock is a small Queen Ann (which I have used before and like very much). Â The rest of the hardware is German silver, which I have never worked with before. Â The following photos will show the rifle as Richard delivered it to me.

I will post some photos on the progress to date next time around....

Personally, I had also started a matched set of 1/2 scale rifles for my two daughters many, many years ago that I have never finished. Â And, in the natural order of things, the girls had not waited on me and are now both grown women. Â So, secondarily, I wanted to do this for Richard to make up for my own missed opportunity.

At any rate, I have been working on it a little at a time, and asked Richard if I could post the work here as it might be of interest to this community. Â He said to go ahead, so here goes.

It is always a bit of an issue to take over someone else's project, as you are never quite sure what the original vision was. Â Also, half way through a build, there are things that have been done that cannot be undone, without completely starting over, and must just be lived with. Â Luckily, Richard had done a great job up to the point he had to stop and turned the work over to me.

The rifle is 3/4 scale, suited for a child but easily handled by an adult. Â I was immediately taken with the size and style. Â It is a handy little rifle with an octagonal to round .45 caliber barrel. Â The lock is a small Queen Ann (which I have used before and like very much). Â The rest of the hardware is German silver, which I have never worked with before. Â The following photos will show the rifle as Richard delivered it to me.

I will post some photos on the progress to date next time around....