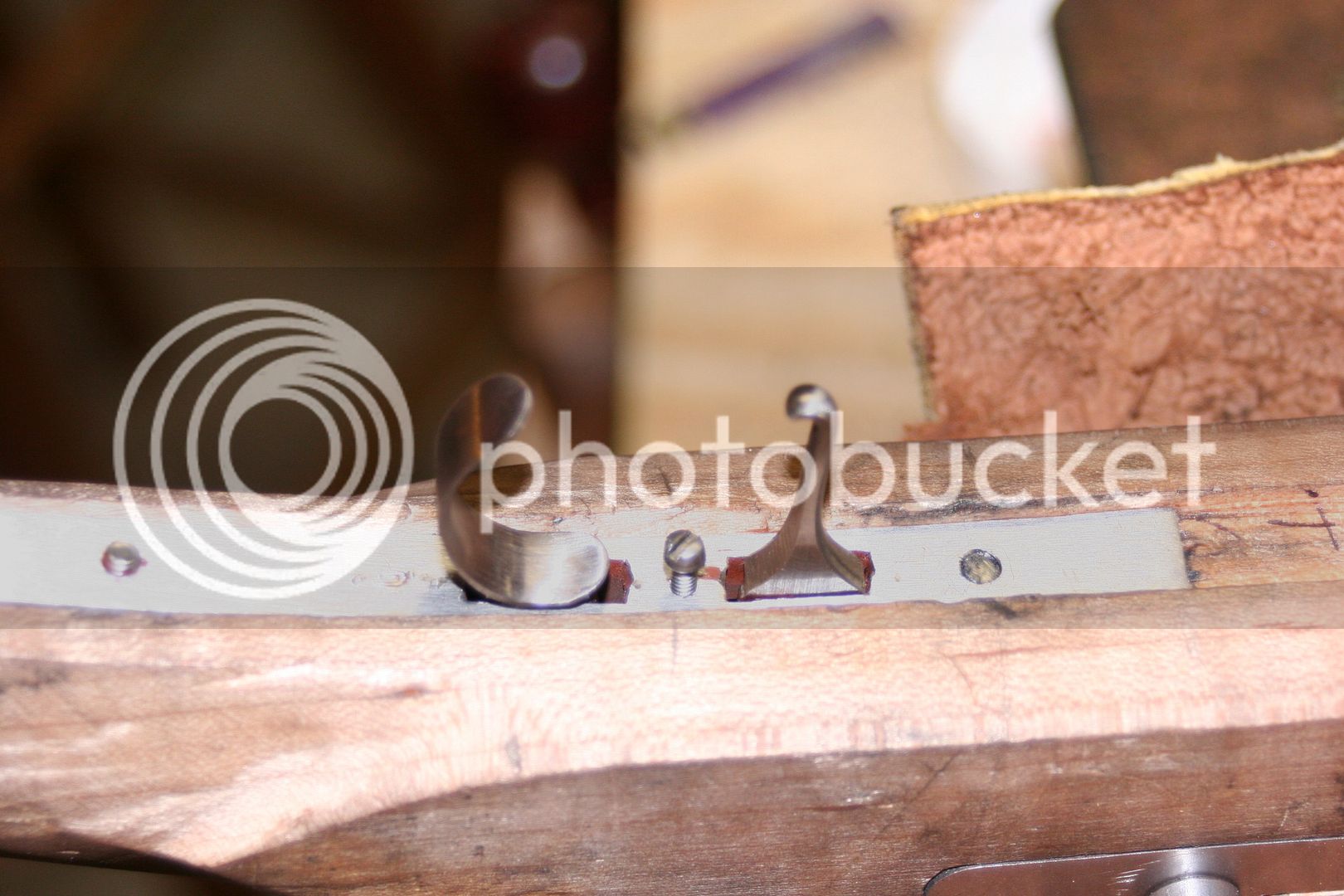

IMHO, Most newbie rifles need Accraglassed under the breech. Ones I have seen usually end up with too much wood hogged out under the barrel, as the builder has issues getting the barrel back & finding the culprit causing the hangup.

Accraglass doesn't hurt a thing & is very helpful when used in the correct instance. Hidden in the breech area under a barrel to make a perfect breech fit is a good instance.

If not, if that barrel starts slamming against a few pieces of pronounced wood instead a solid piece, things start cracking & moving. :shake:

Keith Lisle

Accraglass doesn't hurt a thing & is very helpful when used in the correct instance. Hidden in the breech area under a barrel to make a perfect breech fit is a good instance.

If not, if that barrel starts slamming against a few pieces of pronounced wood instead a solid piece, things start cracking & moving. :shake:

Keith Lisle