kmolett :

As was mentioned, the sear spring has nothing to do with the half cock or full cock except to push the sear against the outside of the tumbler and into the half cock notch or the full cock notch when its nose gets to either of those positions.

I see nothing wrong with the half cock engagement of the nose of the sear in the picture in post 703122 (top picture). It is fully engaged with the notch and without something breaking it should not come out of the notch until the hammer is further raised.

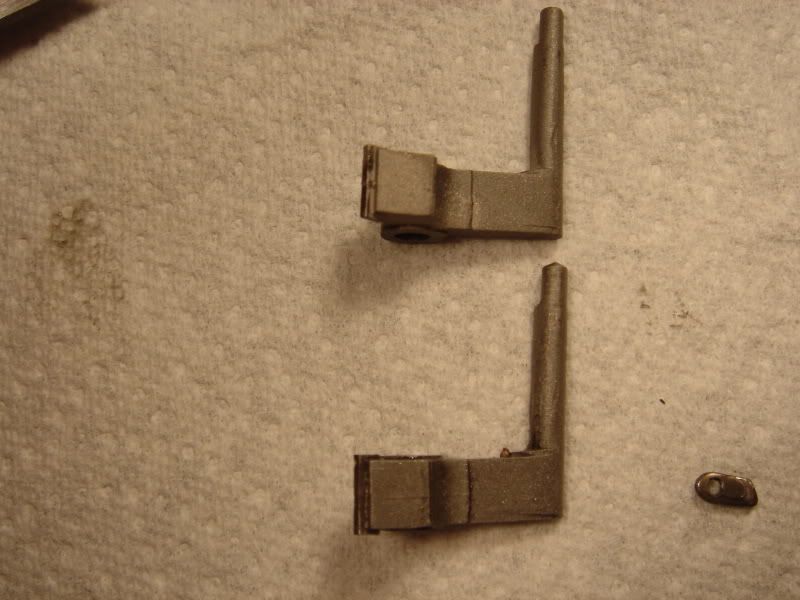

I also don't see anything wrong with the trouble making sear in post 703119 except there seems to be a little wear where the fly would rub against it.

The little fly in these L&R locks will only work when they are installed one way.

Although you can install them backwards if you do, they will not keep the sear from having problems with the half cock notch.

That is one of the big pluses for the Siler locks IMO. The Siler can't be assembled wrong.

I'm sure you are aware of this but for the folks who are new to locks with flys in them allow me to talk a little about how these flys work and one of the dangers in working with a lock with a fly.

From the "hammer down" position as you raise the hammer the nose of the sear will ride against the outside of the tumbler. When it reaches the half cock position the nose of the sear pushes the fly upward towards the full cock notch and out of the way so that it can enter the half cock notch.

Further raising the hammer causes the nose of the sear to jump over the fly and then back against the surface of the tumbler until it reaches the full cock notch which it then enters (if the sear spring is doing its job).

When the sear is released from the full cock notch it again approaches the fly but this time the fly moves downward blocking off the entry to the half cock notch.

As the sear cannot enter the half cock because the fly is in the way it jumps over the fly and allows the hammer to continue to fall.

Notice that as the hammer is falling from the full cock position, the fly keeps the sear from entering the half cock notch.

With this in mind it becomes obvious that lowering a hammer from the full cock position in an attempt to reengage half cock is impossible if the fly is doing its job correctly.

The only way to get a hammer from full cock to half cock is to lower the hammer down further than the half cock position and then raise it back upwards to half cock.

Some people who are unaware of this have lowered their hammer from full cock to "half cock" and if this is done slowly sometimes rather than just jumping over the fly the nose of the sear will actually "hang up" on the fly.

This can be very dangerous because just the slightest bump or touch of the trigger will cause the sears nose to loose its grip on the fly and to jump over it allowing the hammer to fall.

My suggestion is, with the lock out of the gun run the hammer thru several cycles of "hammer down" to half cock (watching the sear push the fly out of the way and snapping into the half cock notch). Then raise the hammer to full cock again watching the sear push the fly upwards, jumping over it and then snapping into the full cock notch.

Then lower the hammer slowly watching the nose of the sear push the fly down so it covers the half cock notch, then jump over the fly and allow the hammer to fall.

Only when the lock is doing all of this correctly should you reinstall it into the gun.

Remember, if the fly is installed backwards, it will not work correctly so if the lock isn't working correctly, remove the fly, turn it over and then reinstall it.

After reinstalling the fly and the rest of the parts run the lock thru the above cycles again and make sure it is working properly.

Oh, you don't have to install the mainspring to run the lock thru these cycles but the sear spring must be installed to make sure it has enough pressure to keep the nose of the sear against the tumbler at all times except when its jumping over the fly.