Brokennock

Cannon

Very happy you're bouncing back.Hi Folks,

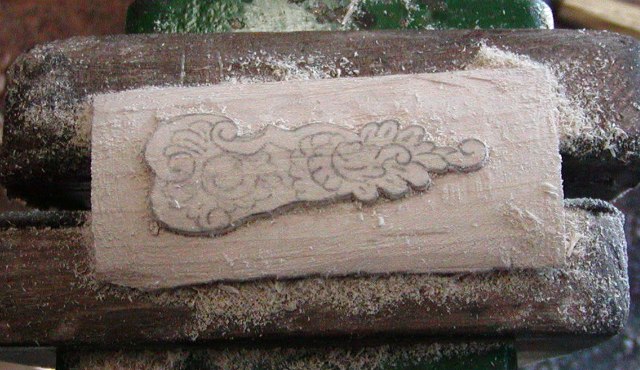

I was down for most of a week after getting my Covid 19 vaccine. It whacked me pretty hard but I am back to normal. The Hawk fowler is one of the hardest guns I've ever made. There are no components you can buy that can simply be used. Everything has to be modified extensively or made from scratch. I think I could make 2-3 other guns from rough blanks or 25 Kibler kits in the time required for this one gun. My next challenge is the butt plate. I bought a wax cast French trade gun butt plate that will provide the base. I peened and stretched it longer and wider. Then I reshaped the heel of the plate and cut off the forward finial to be replaced by one matching the Hawk fowler. To make that finial, I had to cast it. First I scaled a photo of the original finial and traced its outline and details. Then I shaped a piece of hard maple and glued a little handle on the under side. Holding the maple blank and handle in a vise, I traced the return on to the wood using graphite paper.

Then I carved the tang in 3D relief.

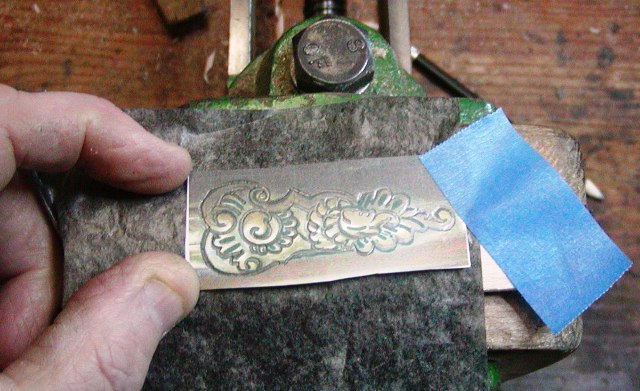

I cut off the handle and trimmed away the excess wood so I could use the carving as my model for casting. I used Delft clay to make a 2-piece mold, melted brass in my oven and poured the casting.

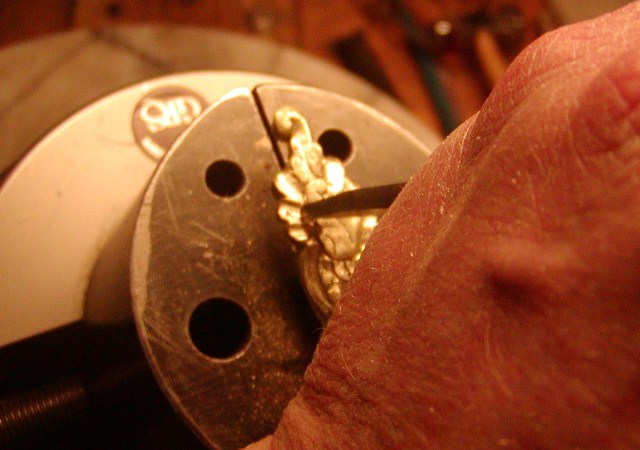

I also cast the front finial for the trigger guard, for which I had an existing suitable model from my previous Hawk fowler.

Now I need to trim the castings, glue them to a base, and then chisel the details and polish them. After that, I will show how I construct the parts.

dave

Thank you for sharing all this with us, I know these posts take a lot of time and effort on top of what you are putting into the guns you are posting about.