Hi,

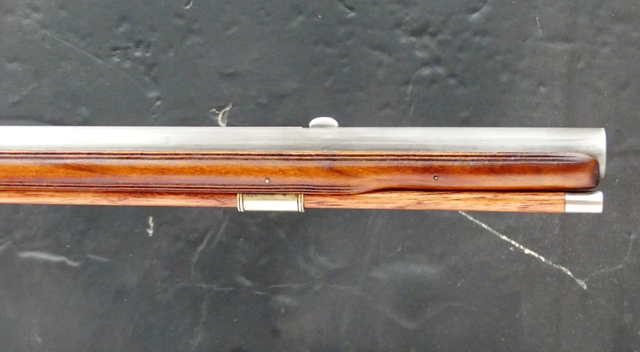

Thanks Rich and Jennison. The fowler is almost done. I should be able to post final photos on Sunday or Monday. The front sight is mortised into the barrel but I also added solder for insurance.

I had a left over silver sprue button so I melted it in a crucible so gravity formed it into a perfect little round button in the bottom of the crucible. Then I hammered and flattened it into a perfect round shape on my little anvil. Next I cut it in half to make the half moon sight. I marked its dimensions on the barrel after finding the center. I mark the center of the barrel by laying it upside down on a flat surface. The flat barrel tang and top flat of the octagon section hold the barrel horizontally level on the bench. I put a thin file under the barrel where the sight is located and draw it out from under the barrel. That makes a perfect center mark on the round part of the barrel near the muzzle. The sight is located almost 5" back from the muzzle where the flat sighting plane ends. I cut the outline of the base into the barrel using a square graver and a series of parallel lines lengthwise in the mortise. Here are photos from a pistol I made.

Using a 1/8" wide flat bottomed die sinker's chisel, I cut out the mortise.

Then I go around the edges with a knife edged chisel that undercuts the edges. I use a tiny triangular file to cut little dovetails in the ends of the sight and connect the tops of them on each side with tiny grooves cut with a jeweler's saw. I flux the mortise and sight, tap it into the mortise, which holds it in position. and then sweat solder from one side of the sight to the other. After soldering, I clean up the excess solder, and then peen the barrel along the ends and sides of the sight with a hammer and punch so the steel barrel locks the sight in place. It should hold fine even without the solder. I don't measure any depth or do any machining. It is all done by eye and it goes very quickly.

I drilled the 5/64" diameter vent hole. The owner does not want a vent liner, just a hole like the original. Under that circumstance and given the thick barrel walls at the breech, I am no fan of the "sunset" position of the hole relative to the pan on the lock. I want the hole buried a little bit into the pan. As Larry Pletcher showed in his tests, the radiant heat from the pan that ignites the charge peaks after priming powder burns down into the pan a little. With a thick barrel wall and simple touch hole, the peak of radiant heat means more reliable ignition. It does not mean the fastest ignition. There is a trade off. That is why you generally see vent holes lower than "sunset" position on most military guns. Anyway, this gun has a relatively big vent hole positioned just below the top of the pan. It will be very reliable and representative of the guns from the time.

I made the ramrod. On this gun even the ramrod was a challenge. It had to be tapered, which I do on my lathe. I can only get 48" hickory blanks so I had to add 2 inches. I made a long iron ferrule to add that length and made and attached a spring steel tow worm. The worm is tightly hammered into a hole in the ferrule and then soldered.

The original gun also has a rod with a silver tip at the muzzle. So I turned the end of the rod to form the internal diameter post for the tip. Then I cut silver sheet the size needed, annealed it, and bent it around a drill the inside diameter of the ferrule. I measured the silver so the butt joint was exactly at the right diameter. Then I low temp silver soldered it together. I fitted the collar to the rod making sure the end of the wood would support the silver end cap. I scribed a circle in silver sheet, cut it out with a jeweler's saw, and tinned it with solder. Then I laid it on top of the silver collar and heated it until it sat down and was soldered in place. Then I ground off the excess, glued the tip and tow worm to the ramrod, pinned the ferrule for the worm, sanded the rod, stained and started coating it with finish.

dave