Beautiful!

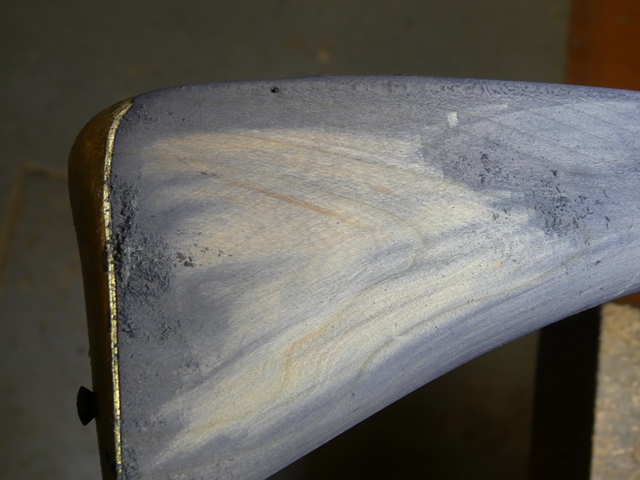

What do you call that feature where the trigger guard is mounted on the raised moulding? It certainly is eye catching and I imagine it lets you make the stock that much slimmer.

Great photo of Willow- And your vista is inspiring I am sure!

What do you call that feature where the trigger guard is mounted on the raised moulding? It certainly is eye catching and I imagine it lets you make the stock that much slimmer.

Great photo of Willow- And your vista is inspiring I am sure!