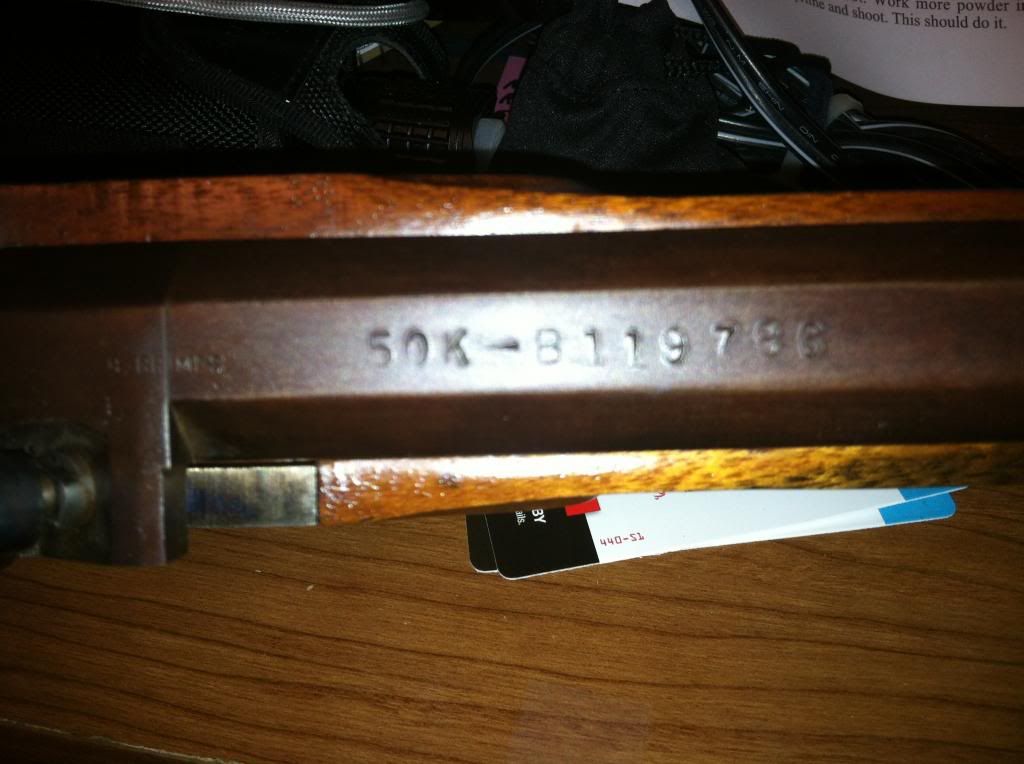

I just bought a .50 cal Hawkens style BP rifle and need help in identifying it so I can determine which nipple to buy so I can replace it. There are no manufacture markings that I can tell. It has "B. Grimes" in very small stamped letters and " 50K- B119786" ( 1/4 in letters) on the top of the barrel between the hammer and rear sight. It has an octogon barrel. I would post an image but I am new to this forum and obviously don't know what I am doing. Any help would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help identifying rifle

- Thread starter Hardy

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,350

looks like one of the many "eyetalian" clones of the t/c hawken produced by investarms under many names. they're well made guns & this one looks to be in pretty good shape & should be a decent shooter for ya. luck & have a good'en, bubba.

I agree with bubba, it is an Investarms, should have a barrel stamping "I" in a box on it, the nipple is a 6-.75mm metric, just bought some from Tack of the Wolk, part number RLP-S. Nice color case hardening on the lock also.

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 15

the patchbox is the type installed on rifles imported by INVESTARMS in the 70's....if I remember correctly...

I looked for an "I", but can't see any marking other than the one in the picture. I have a Pietta revolver that has some 6 .75 nipples so I will check the threads out to see if they will fit. Thanks to everyone for your help! Can anyone tell what the riflings are by the picture?

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

Its an investarms rifle no doubt about it the patch box is a tell tale sign. But most of there models were made using TC Hawkens parts (triggers, buttstock, nose cap, locks) however this is when they were using the Lyman GPR lock and barrel (using one lug) if I am not mistaken this barrel will drop into the deer stalker stock as well. Investarms is owned by Lyman or vice-versa. Over all its a quality gun. The reason it may not have the tell tale I was they made a lot of these guns more major retailers such as Cabelas. I have the Cabelas Hawkens ( The TC style) and "I" is there. My hunting buddy back in Michigan has the same gun but Cabelas Hawken is there but the "I" is not. :idunno: But I will stake my reputation as a Hawkens man that's what you have. An Italian made Investarm, made by Lyman Hawkens rifle using the GPR lock and a deerstalker barrel. One more detail the barrel should be 15/16 as well let me know if it isn't.

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

Ok upon re-inspecting the picture the barrel has the TC sights on it. I am going with that this is the transition period rifle when they went away from using TC parts but still had left overs. All the above post still applies. I'd be interested to know if its got metric or standard threads on the breech. Because my investarms has a standard thread using the TC patent breech. Being as though it has TC sights makes me wonder if its the TC barrel and the rare Lyman breech plug in standard threads fitted to the TC barrel. Until they burned through the surplus stock before switching to all metric.. :hmm: :idunno: If the rifling is 1/48 its likely the TC barrel, if its 1/60 its the lyman barrel

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

Theres also pictures of the Investarm Cabelas Hawkens on the forum in the for sale section. This one is like mine uses mostly all TC Hawken parts.

Looks like the Lyman/Investarms Trade Rifle.

As far as I know they all came with 1:48 twist rifling. The GPR has the 1:60 twist but it has 2 lugs and is 32" long vs the 28" Trade Rifle barrel.

There was an earlier rifle called, I believe, the Great Plains (not the Great Plains Rifle) that had one lug but it had a different patch box.

Somebody jump in and correct me if I'm wrong.

As far as I know they all came with 1:48 twist rifling. The GPR has the 1:60 twist but it has 2 lugs and is 32" long vs the 28" Trade Rifle barrel.

There was an earlier rifle called, I believe, the Great Plains (not the Great Plains Rifle) that had one lug but it had a different patch box.

Somebody jump in and correct me if I'm wrong.

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

You bring a valid point to the table however the lyman/Investarm trade rifle didn't run TC sights they ran the sights like the ones on a GPR. Most trade rifles had no patch box and a single trigger. However they did offer if with the same patch box and a double trigger. But still doesn't account for the TC sights.

AZbpBurner

54 Cal.

Gunclinger said:I looked for an "I", but can't see any marking other than the one in the picture. I have a Pietta revolver that has some 6 .75 nipples so I will check the threads out to see if they will fit. Thanks to everyone for your help! Can anyone tell what the riflings are by the picture?

You may want to consider an actual rifle nipple, instead of the shorter pistol nipple. I have a set of spare nipples for a Pietta revolver - they're 5.5 x .9mm and also significantly shorter than the 6 x .75mm rifle nipple.

The nipple on your rifle looks short & not original to the rifle. A shoulder or seat on the nipple body above the threads, may not be correct & may not provide proper gas seal upon firing.

You may also consider a musket nipple if you plan on using Pyrodex or Foo-Foo powders. Personally, I've never had issue with #11 caps & Pyrodex, but others have.

Treso/Ampco Nipples are tough & worth the price. Jedediah Starr has the best selection of Ampco & Track of the Wolf has stainless musket nipples.

Get a rifle nipple wrench, since your revolver wrench won't fit.

Best to check on availability of musket caps first, before ordering a musket nipple - and check to ensure your hammer strikes the rifle nipple squarely & in the center of the hammer face, since any offset or misalignment in hammer strike on the larger diameter musket nipple may cause problems.

Your rifle is definitely made by Investarms, and shares a positive reputation with Lyman, Cabelas, Thompson Center and maybe others, who all marketed the same rifle.

To use the double set triggers, you set with the rear, and fire with the front - it will also fire unset. Check to ensure that when you set the triggers, the hammer will go into and remain at full cock. In normal use, you would first fully cock the hammer, and then set the trigger. If it doesn't feel safe, or won't set properly, the trigger assembly can be removed and adjusted. For any adjustment, just ask and a number of folks here can walk you through adjustment.

If you haven't already, consider removing trigger assembly, lock and barrel. On the barrel is the underlug where the ramrod thimbles are located. In a used rifle, this is an often overlooked item, but it is a simple matter to unscrew thimbles/underlug and clean underneath. Use RIG or a quality grease to coat the barrel surface before reassembly. It is likely this has never been cleaned before - for many folks' rifles, too.

Remove the cleanout screw from the drum and scrub out the access with a pipecleaner saturated with soapy water - you want it to be clean & free of any accumulated scale or crud for best ignition.

Your barrel most likely has a 1:48" twist rate. You can easily verify this by inserting a tightly patched cleaning rod, placing a mark on a piece of tape stuck to the rod right at the muzzle. I wrap the tape, leaving a little tab sticking out too - withdraw the rod, watching for that tab to make one half revolution. Measure the distance from muzzle to mark on the tape and multiply by 2. You should end up with a number amazingly close to 48". The reason for measuring 1/2 turn on the rod is that your barrel isn't likely long enough to be able to make one full turn.

Contrary to what you may have read elsewhere, 1:48" twist isn't a compromise barrel at all, since it was common for original Hawken Rifles.

A good load to start with is 65-70 gr. 3F Black Powder or Pyrodex. You can fine tune to determine your rifle's preference for best accuracy by increasing & decreasing powder loads by 5 grains. Shoot at least a 5 round group using each load before trying the next, then simply select the tightest group. I like to swab the bore after every 3 rounds fired. You can use anything from that Old WWI GI Bore Cleaner, to a mix of 50/50 water + alcohol and a little dishsoap in a small squeeze bottle. Alcohol helps the bore to dry prior to dispensing the next powder charge.

Shoot from a bench, take your time, and you should easily be able to produce a group around an inch or so with all hits touching at 50 yards.

When reinstalling your lock, don't overtighten the retaining screw.

Also, be sure your brass ramrod tip has been cross pinned; chances it hasn't been, so simply drill a 1/16" hole thru the brass, insert a tight-fitting piece of wire or finishing nail, trim a little above flush on both ends, peen down, then file flush. This prevents the brass end from coming off in the event you have it stuck down the bore with a tight fitting patch or brush - I'm guessing the end opposite the ramming end is threaded.

Also look for a stamp on the barrel: 2 Letters inside a rectangle, or maybe even Roman Numerals. This is the Italian proofhouse date and closely correlates to the manufacture date. Let me know what you find & I can check the chart & give you the date.

AZbpBurner

54 Cal.

One last thing: Your barrel wedge should be inserted from the right side.

Opps I lost the image of the end of the barrel, but it measured 15/16.

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

Its a 15/16 barrel. No doubt you have a Lyman/Investarm/TC Hawkens. Theres parts from all three companies on there. Either way the gun is well made and will do very well for you. It appears to be in great shape and should serve you well. If you ever need parts there easy to come by. Feel free to contact me by sending a private message if you have any questions or concerns.

I think I'll change my mind and call it an Armi San Marco - I was browsing GB and came across the spitting image of your rifle, missing the rear sight, seller is calling it an ASM. I would link to it but I think that is against forum rules, go to gunbroker and search under BP rifles and you will find it.

Similar threads

- Replies

- 18

- Views

- 1K

- Replies

- 4

- Views

- 570