Hawken kit from Cabela’s I bought about 30 years ago.

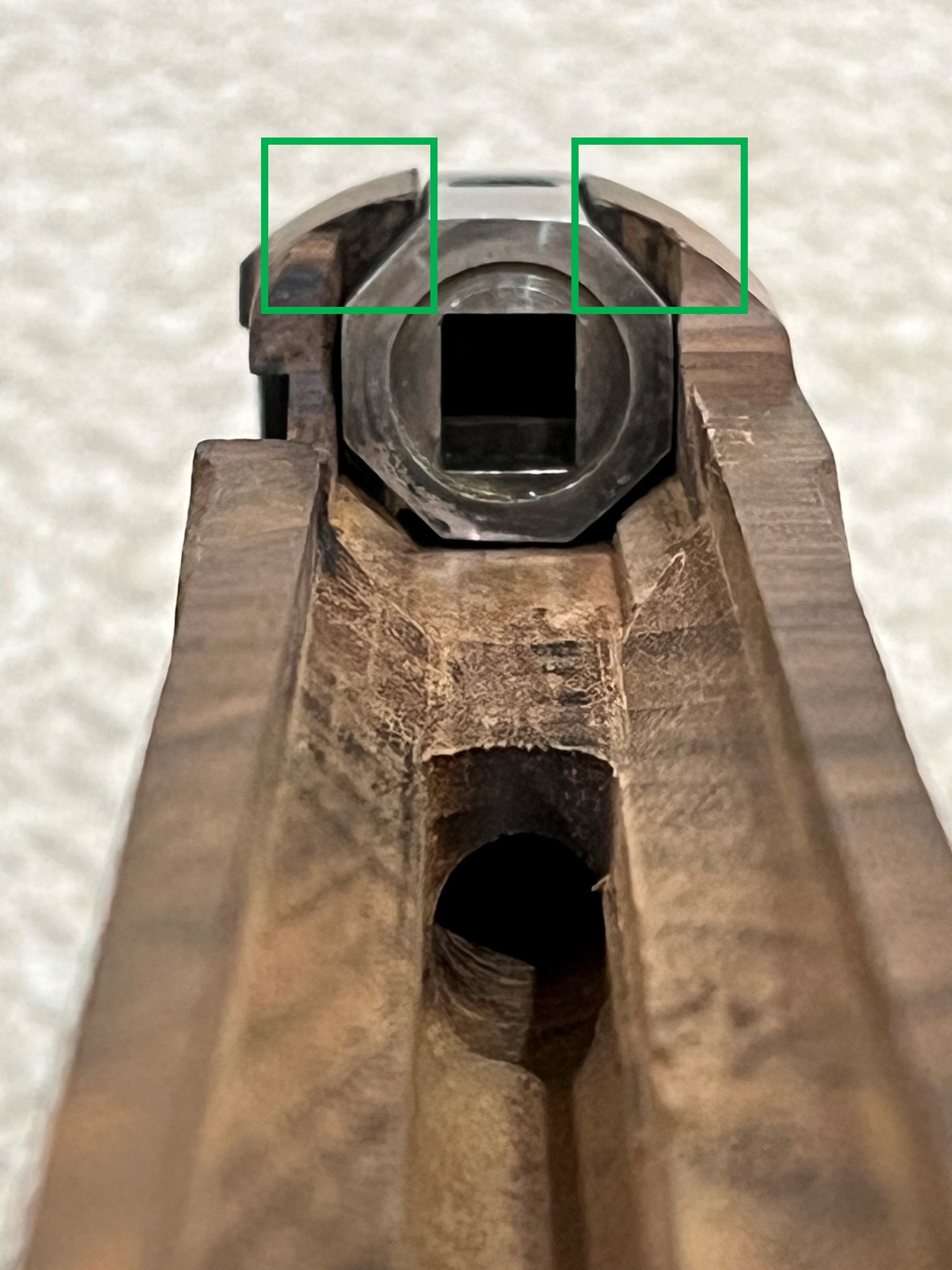

I’m not sure how to finish the wood to the left and right of the breech plug. The wood sticks above the the angled flat on the barrel. Never found a good picture of how they were originally finished. Not looking for exact reproduction, just something not “wrong”.

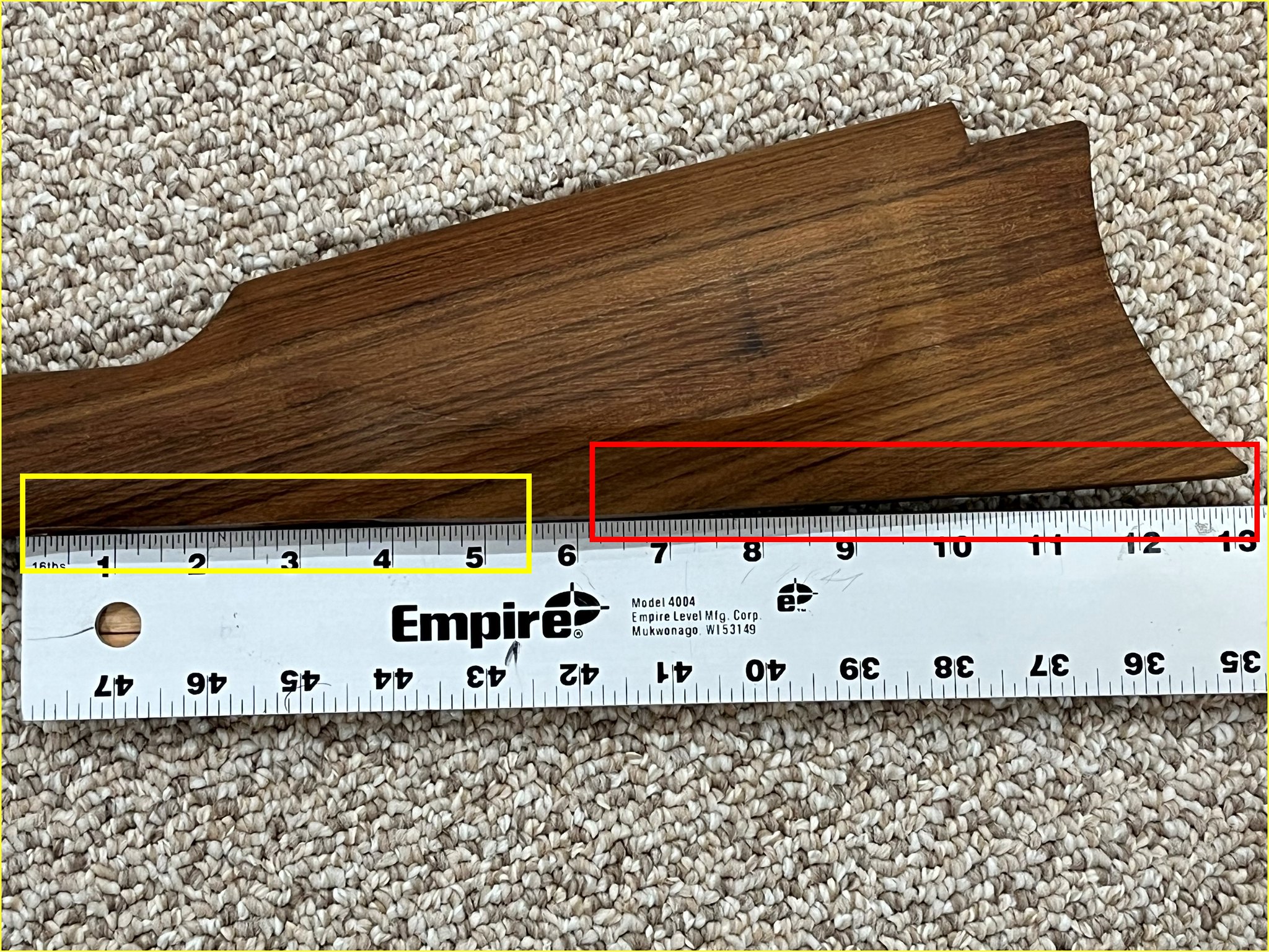

Bottom of the stock looks straight from trigger guard to butt on all the photos I’ve seen. Mine has a hump where the back end of the trigger guard attaches. Would I be wrong to flatten that area and reinlet the back trigger guard attachment? Or is there supposed to be a slight hump?

I’m not sure how to finish the wood to the left and right of the breech plug. The wood sticks above the the angled flat on the barrel. Never found a good picture of how they were originally finished. Not looking for exact reproduction, just something not “wrong”.

Bottom of the stock looks straight from trigger guard to butt on all the photos I’ve seen. Mine has a hump where the back end of the trigger guard attaches. Would I be wrong to flatten that area and reinlet the back trigger guard attachment? Or is there supposed to be a slight hump?