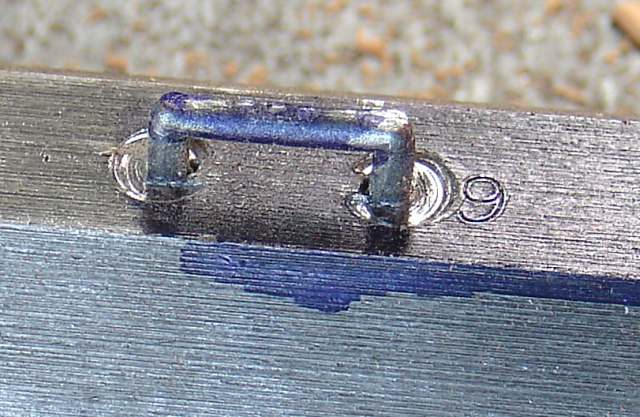

Uncle and I were looking at the totw catalog at the instructions for installing barrel staples and it seemed a bit confusing to us.

They want us to stake one side of staple before the other but the wording on where the other side of staple is resting is ambiguous.

They speak about not worrying about deforming staple since that can be corrected. Can we assume you put both ends of staple in the holes but only tap on the one side to drive it to bottom of hole before peening edges?

I can't imagine that them mean to have only one end of the staple in the hole when peening the first side but the instructions sorta imply that.

We need a klew or two.

Thanks,

Clutch

They want us to stake one side of staple before the other but the wording on where the other side of staple is resting is ambiguous.

They speak about not worrying about deforming staple since that can be corrected. Can we assume you put both ends of staple in the holes but only tap on the one side to drive it to bottom of hole before peening edges?

I can't imagine that them mean to have only one end of the staple in the hole when peening the first side but the instructions sorta imply that.

We need a klew or two.

Thanks,

Clutch