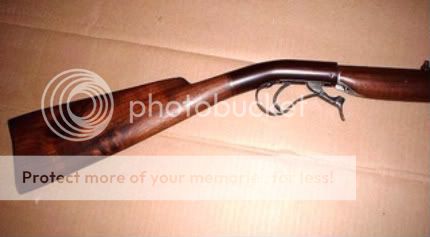

that is great work and a very nice interpretation of the old Hopkins & Allen design. (snips)I can't find anything about how to make the breechplug snug up to the receiver face. Did you use a tapered pin on your installation?

Mike ::

Mike,

I didn't think of taper pins..although I knew H&A did some that way..

Instead I used three 10X32 set screws, located roughly 120 degrees apart. ( In that last pic, the close up, you can see one. )The barrels are breeched and the plug turned down<if required> to a 5/8ths diameter. the end of the frame is reamed to match.

What I did was locate where I thought the holes would go and center marked them. I took the frame to my drill press and used a 'centers-it' V jig, to hold the frame. The trick was, I placed a 1/4" drill bit..under the edge of the jig.< or I could have just rotated my table, but I was working on the fly ::> This created a 10-15 degree slant, rearward, when I pre drilled the holes using a smaller bit.

I then drilled and tapped

one for the appropriate thread and put the barrel on. by making sure the barrel was seated tight, I locked that screw in. Then I just drilled the other two for their tap size, extending into the breech stub. after I finished tapping those and setting the screw, I retured to the first position and finished it to depth. Finished the 'seats', in the stub, to just larger than screw size..

All this sounds like a lot, but it creates a nice tight seat. the barrel is deffinately staying put, once you put it in the frame! and since the seats are drilled at a rearward angle.( front to rear, if I hadn't made that clear? :redface: ) when the screws are socked down, they actually pull the barrel in tighter against the frame.

I could take a pic, showing the breech stub, if anyone thinks that is needed? I could probably get away with just using two screws,, but like having the extra security, i guess? and I could use slotted screws, instead of allen head set screws, if someone was gonna gripe about being PC.

( I'd argue, it is PC for a 2005 Mar/Dag gun!! )

Hope I made some of this clear??

Respect Always

Metalshaper