Thank you sir, the last thing I needed to go with my insomnia was a bad case of the church giggles. Looks like I'll be spending what's left of the night in the guest room.After much frustration I impulsively hammered out this spoon handle and super glued it to the barrel. I feel like I’ve made a mess of this but to my surprise it shoots well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Look at this mess

- Thread starter Gowacky

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well, at this point the homemade peep sight is the least of my worries. I’m shooting daily but having mixed success. It’s been below freezing and wet but for whatever the reasons the gun doesn’t shoot every time. I’ve had the most trouble with the cap firing but not igniting the charge. Then quite often the cap won’t fire until the 2nd time the hammer drops.

But, just recently started swabbing with a patch wet with alcohol. Then I follow with a patch that has mink oil on it.

I was thinking I needed to pound on the side a bit to encourage my FFF to trickle under the nipple better.

Anyway, right now it’s firing every time so I need this to continue.

But, just recently started swabbing with a patch wet with alcohol. Then I follow with a patch that has mink oil on it.

I was thinking I needed to pound on the side a bit to encourage my FFF to trickle under the nipple better.

Anyway, right now it’s firing every time so I need this to continue.

Your swabbing method may or may not be a part of the problem with the mis-fires.

If you are shoving the dampened patch down the bore and then pumping the ramrod up and down to scrape off the fouling before removing it, you are causing loose fouling to blow back into the flame channel that runs from the bottom of the nipple to the bore. That can cause a lot of mis-fires.

The right way to swab IMO, is to dampen the patch and shove it all the way to the breech in one smooth motion. Then, let it sit there for 3-5 seconds to allow the alcohol or water to soak into the fouling on the bore. After this wait, pull the ramrod and wet patch back out of the bore in a slow, smooth manner.

The wet fouling will be wiped out of the bore without loose fouling getting blown back into the flame channel.

You can follow this with a dry patch to dry off any dampness that remains in the bore but IMO it really isn't necessary.

If you haven't done it, buy some pipe cleaners. The kind pipe smokers use to clean the pipe stem.

When you clean your rifle, wet a pipe cleaner and run it thru the flame channel under the nipple. You should be able to see it coming into the bore if you peek down it with a flashlight.

Then, remove the pipe cleaner and run a clean, dry one back and forth in the flame channel.

Another tip. When you loading the rifle make sure there is no cap on the nipple and the hammer is at half cock. This allows air to be blown out thru the nipple as the patched ball or the bullet is rammed down the bore. The venting air will help to carry fresh powder thru the flame channel to the bottom of the nipple.

Have fun.

If you are shoving the dampened patch down the bore and then pumping the ramrod up and down to scrape off the fouling before removing it, you are causing loose fouling to blow back into the flame channel that runs from the bottom of the nipple to the bore. That can cause a lot of mis-fires.

The right way to swab IMO, is to dampen the patch and shove it all the way to the breech in one smooth motion. Then, let it sit there for 3-5 seconds to allow the alcohol or water to soak into the fouling on the bore. After this wait, pull the ramrod and wet patch back out of the bore in a slow, smooth manner.

The wet fouling will be wiped out of the bore without loose fouling getting blown back into the flame channel.

You can follow this with a dry patch to dry off any dampness that remains in the bore but IMO it really isn't necessary.

If you haven't done it, buy some pipe cleaners. The kind pipe smokers use to clean the pipe stem.

When you clean your rifle, wet a pipe cleaner and run it thru the flame channel under the nipple. You should be able to see it coming into the bore if you peek down it with a flashlight.

Then, remove the pipe cleaner and run a clean, dry one back and forth in the flame channel.

Another tip. When you loading the rifle make sure there is no cap on the nipple and the hammer is at half cock. This allows air to be blown out thru the nipple as the patched ball or the bullet is rammed down the bore. The venting air will help to carry fresh powder thru the flame channel to the bottom of the nipple.

Have fun.

Thanks Zonie, I’ve been swabbing just as you described. What you advise makes good sense and I’ll begin doing that immediately. I had also forgotten that need to use a pipe cleaner on the flame channel. Both those items are sure to help get my powder in place and clean cutting down on misfires.

If I’m going to go to the effort to make a stand and call coyotes, I’d sure like to have more confidence that she will deliver that ball.

Thanks again!

If I’m going to go to the effort to make a stand and call coyotes, I’d sure like to have more confidence that she will deliver that ball.

Thanks again!

- Joined

- Mar 23, 2015

- Messages

- 5,032

- Reaction score

- 3,629

Gowacky, as I read your description of swabbing you wrote you followed the alcohol patch with one with mink oil. Is the mink oil on the patched ball or are you using a mink oil patch and then load the patched round ball? If you are using a oiled patch after the alcohol patch you may be defeating the alcohol patch. Just use the alcohol patch and then your patched round ball.

Also, you mention the cap may not fire until the second attempt. That may be an indication of a cap not fitting all the way onto the nipple. You may need a larger size cap or reduce the size of the diameter of the nipple. First thing to do is inspect the nipple and see if it has a very slight mushroom shape. This usually happens if someone has fired an empty gun without a cap on the nipple. I have had a couple of used gun I purchase with this problem. I dressed off the mushroom and the nipples worked okay until I could replace them.

Good luck and no matter what have fun.

Also, you mention the cap may not fire until the second attempt. That may be an indication of a cap not fitting all the way onto the nipple. You may need a larger size cap or reduce the size of the diameter of the nipple. First thing to do is inspect the nipple and see if it has a very slight mushroom shape. This usually happens if someone has fired an empty gun without a cap on the nipple. I have had a couple of used gun I purchase with this problem. I dressed off the mushroom and the nipples worked okay until I could replace them.

Good luck and no matter what have fun.

Thanks KJ, that’s exactly what I’ve been doing. Running an alcohol patch then running a patch w mink oil. Thought I was cleaning the fowling w the alcohol, then just greasing the barrel for easier loading w the mink oil.

I’ve had a time with the nipple. I bought 3000 CCI Magnum caps only to find they fit loose on the Traditions Crockett factory nipple. I’ve brought in a couple of different ones and have one in that takes the cap snuggly. But I felt the hammer wasn’t hitting the nipple squarely from the beginning (new gun). I thought I could get it working and didn’t return it to Traditions. I still don’t think it’s aligned as well as it should be. I tried to file down the hammer stop but couldn’t get to it very well.

I’ve had a time with the nipple. I bought 3000 CCI Magnum caps only to find they fit loose on the Traditions Crockett factory nipple. I’ve brought in a couple of different ones and have one in that takes the cap snuggly. But I felt the hammer wasn’t hitting the nipple squarely from the beginning (new gun). I thought I could get it working and didn’t return it to Traditions. I still don’t think it’s aligned as well as it should be. I tried to file down the hammer stop but couldn’t get to it very well.

I also have fought with F2F's from swabbing. After swabbing, firing a cap before loading has helped to reduce the amount of F2F's I've had.

Last night I turned my jag down a bit too, we'll see how that works when I go shooting today. The idea behind turning the jag down is for it to go smoothly down the bore without pushing the fouling down, but then bunches up and drags the fouling back out of the bore.

Last night I turned my jag down a bit too, we'll see how that works when I go shooting today. The idea behind turning the jag down is for it to go smoothly down the bore without pushing the fouling down, but then bunches up and drags the fouling back out of the bore.

From post 46. My opinion and mine only why your having trouble firing.

1. Your gun is no fixed yet still to fire. You do not have the skill level to fix it. Return it to the maker as you were advised.

2. You do not yet have the proper tools to clean it. Get some correct jags and make sure the fit right. Refer to 1 on skill level however.

3. You need a club or someone who is experienced with ML. The net will not work as you have been advised before on the firing of your gun and ignored it.

Please don't get embarrass or mad. Get you gun fixed you paid good money for it and it should work. Get your money worth.

Good luck getting it working

1. Your gun is no fixed yet still to fire. You do not have the skill level to fix it. Return it to the maker as you were advised.

2. You do not yet have the proper tools to clean it. Get some correct jags and make sure the fit right. Refer to 1 on skill level however.

3. You need a club or someone who is experienced with ML. The net will not work as you have been advised before on the firing of your gun and ignored it.

Please don't get embarrass or mad. Get you gun fixed you paid good money for it and it should work. Get your money worth.

Good luck getting it working

I like it and you may even lose weight!

Nit Wit

Nit Wit

There are some well meaning people on here as well as some condescending know-it-all’s.

To those who contributed well intentioned information, I thank you.

To those like Moose and red dog I’d like to remind you there are many ways to skin a cat.

Like Thumpers mother told him, if you can’t say something nice don’t say anything at all.

To those who contributed well intentioned information, I thank you.

To those like Moose and red dog I’d like to remind you there are many ways to skin a cat.

Like Thumpers mother told him, if you can’t say something nice don’t say anything at all.

Newtire

32 Cal.

- Joined

- Oct 25, 2009

- Messages

- 635

- Reaction score

- 498

Was out shooting some clays (or trying!) and a guy came over and gave me some advice about FTF's. Been doing this ever since. I put about 1/2 a charge in the bore with a wad only and set that off. Afterwards, have "0" FTF's . Worked for me.

I’m happy to report zero FTF in the last six attempts.

My primary problem was the cap was firing but not the charge. I’ve began doing as suggested by wet swabbing as little as possible. And I couldn’t find any pipe cleaners but made a bent wire and I’m able to swab that fire tunnel better. So after cleaning it good I’ve started dry swabbing only between shots. I’ve got mink oil on the ball patch only but that has made it easy enough to seat the ball. I also moved up to 30 grains of FFF. Just trying to encourage getting some powder under the nipple.

But then it’s a warm day and it always shot better on warm days.

But I’m changing and learning. Maybe this dry swabbing will be the answer.

BTW, after cleaning and before shooting I don’t doubt that a charge only shot would dry it well and promote good firing.

My primary problem was the cap was firing but not the charge. I’ve began doing as suggested by wet swabbing as little as possible. And I couldn’t find any pipe cleaners but made a bent wire and I’m able to swab that fire tunnel better. So after cleaning it good I’ve started dry swabbing only between shots. I’ve got mink oil on the ball patch only but that has made it easy enough to seat the ball. I also moved up to 30 grains of FFF. Just trying to encourage getting some powder under the nipple.

But then it’s a warm day and it always shot better on warm days.

But I’m changing and learning. Maybe this dry swabbing will be the answer.

BTW, after cleaning and before shooting I don’t doubt that a charge only shot would dry it well and promote good firing.

Well, at this point the homemade peep sight is the least of my worries. I’m shooting daily but having mixed success. It’s been below freezing and wet but for whatever the reasons the gun doesn’t shoot every time. I’ve had the most trouble with the cap firing but not igniting the charge. Then quite often the cap won’t fire until the 2nd time the hammer drops.

But, just recently started swabbing with a patch wet with alcohol. Then I follow with a patch that has mink oil on it.

I was thinking I needed to pound on the side a bit to encourage my FFF to trickle under the nipple better.

It Anyway, right now it’s firing every time so I need this to continue.

I had somewhat similar. Primer pop, either miss fire or bad hesitation. Had switched to pyrodex fff. One thing that helped was to clean nipple and port with welder nipple tool. Wanting to stick with a cleaner burn I swithched to pyrobex "P" in all my guns. No more hesitation and less residue. As far as a primer not popping about all you can do is insure storage stays dry, check for any binding in lock, hammer spring tension and double check the contact point of the hammer. If all looks good and still have issues change nipple.

Well, it’s worked really well today. However, I think there has been a problem with the hammer aligning with the nipple from the start (this is a new gun). But I’ve been reluctant to return it to Traditions. One, because it shoots good today. Two, the factory nipple is too small to hold the caps snuggly. I didn’t know if the factory gunsmith would help me to use the replacement nipple.

Thanks for sharing. I had to laugh out loud, when you expressed your frustration, and took matters into your own hands, due to impatience with the whole deal, first the hammer troubles, and now the not so pleased gunsmith experience! Been there done that with projects that weren't going as planned. Betty, sometimes can tell me, "walk away and cool off!" Sometimes not so much! LOL The silver spoon doesn't look bad to me. I know there are some that would shudder at the thought of it. I admire your ingenuity. If you have a magnet roller maybe you can find the sight still. You have had your share of waiting on this new rifle for sure, and I can understand your patients running thin.

I would contact Brownells if you decide to go with another Williams peep sight. They should be able to get you the right width for the factory dovetail. If you decide to go that route, you will need a dovetail file that is ground safe/flat on all but one side. Skinner sells these files as well. The sights should be slightly oversize (think .001" of inches here, not a lot). The way to do it is file only on one side of the barrel dovetail, going one light stroke at a time, and taking care to keep the stroke even. Check the fit, until the sight slides about 1/3 the way into the barrel dovetail by thumb pressure. If it goes that far, you should be able to tap it in with a brass hammer or plastic dead blow hammer, and finish with a brass punch the rest of the way in. At that point you should have enough of a press fit that you can adjust for windage with a brass punch if needed for sighting in. Another old trick is to center punch the flat of the dovetail if the sight is just slightly loose (or epoxy) you can heat it to make it soft again if need be to remove.

It is easy to do, if you take your time. I like to be in the right frame of mind for that job though. Not stressed, rushed, pissed off, agitated, angst or grumpy! Hey, I still have days I'm not like any of that!

If you don't have a drill press and the taps and you want to take advantage of F.G. Fords offer to fix your spoon sight for height adjustment that would work.

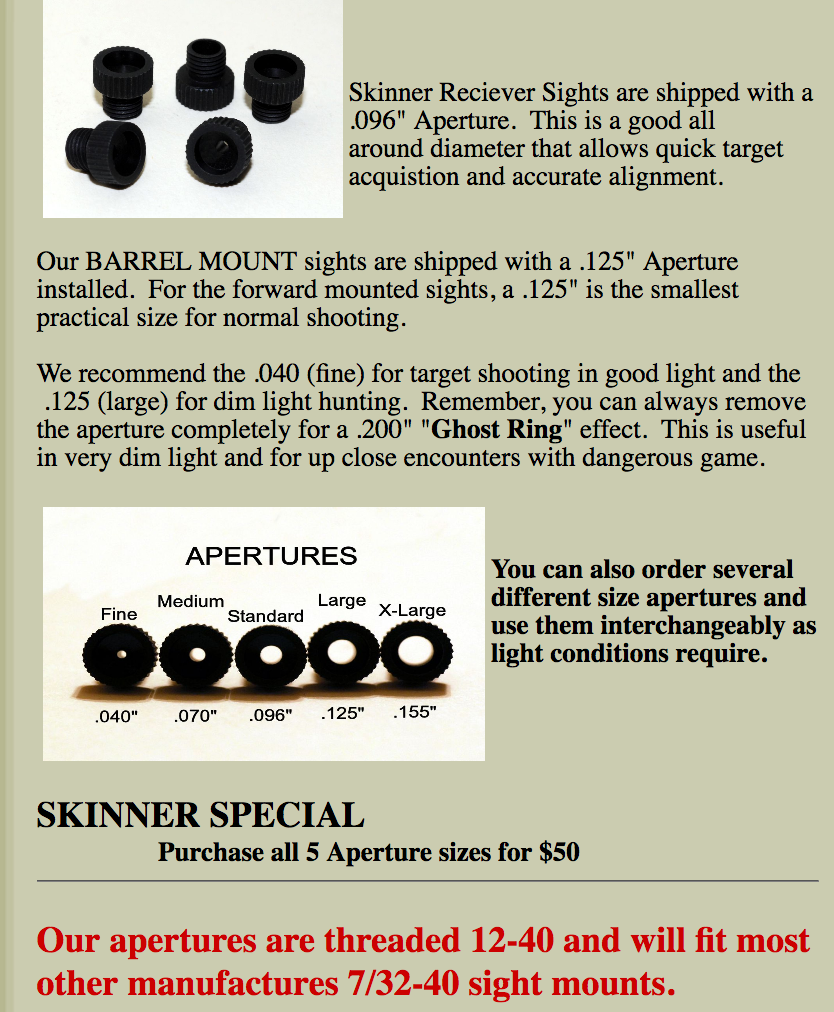

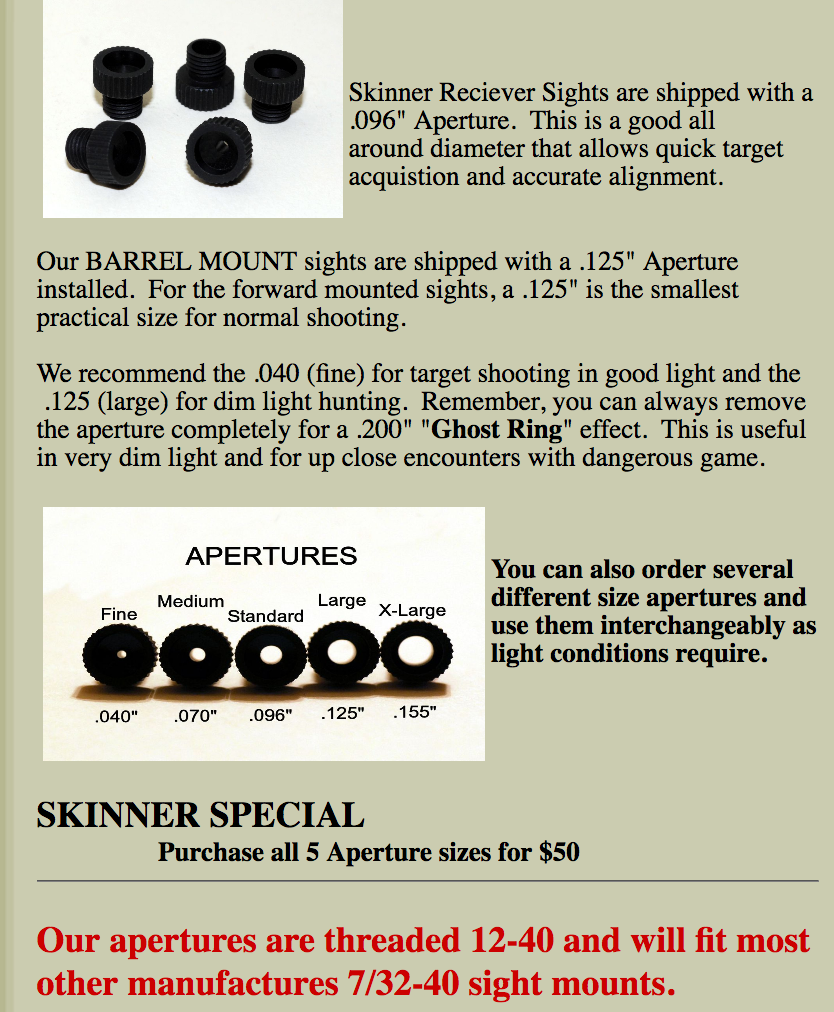

Also, Skinner Sights has screw in peep sight that you could drill and tap the spoon hole for, that way you can change peeps from Ghost sight to, small hole for fine target shooting. Click on the link below for

more info.

http://www.skinnersights.com/apertures_8.html

You would have to use a nut on the other side of the spoon since the spoon is so thin, and lock-tite of course. You have a ton of options here.

Another thought is low temp silver solder from Brownells. I'm impressed with the groupings your getting at 80 yards, so if you decide "if it ain't broke, don't fix it" that works for me too! I like the silver spoon with the built in engraving. Looks pretty cool to me! Bit of a large blind spot with the size of the spoon end, compared to peep hole, but again. I can't give you any grief with those groupings, and if you shoot with both eyes open probably don't even see a blind spot.

You think outside the box GoWacky. I like that.

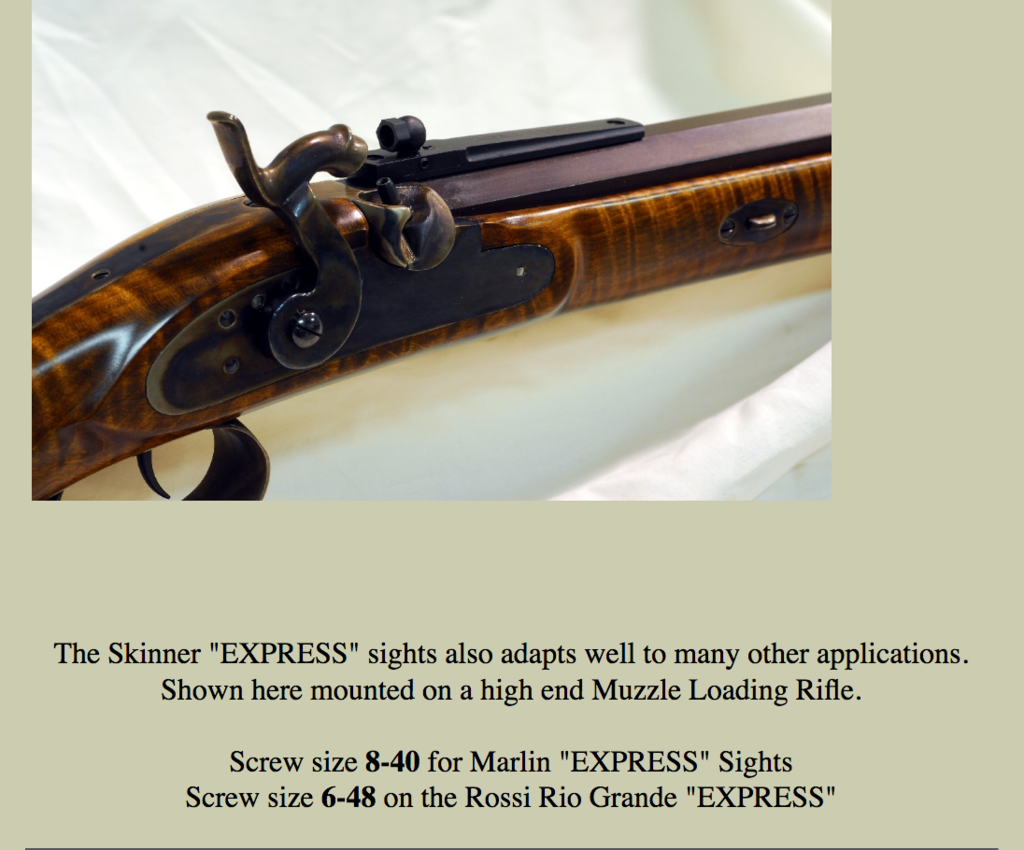

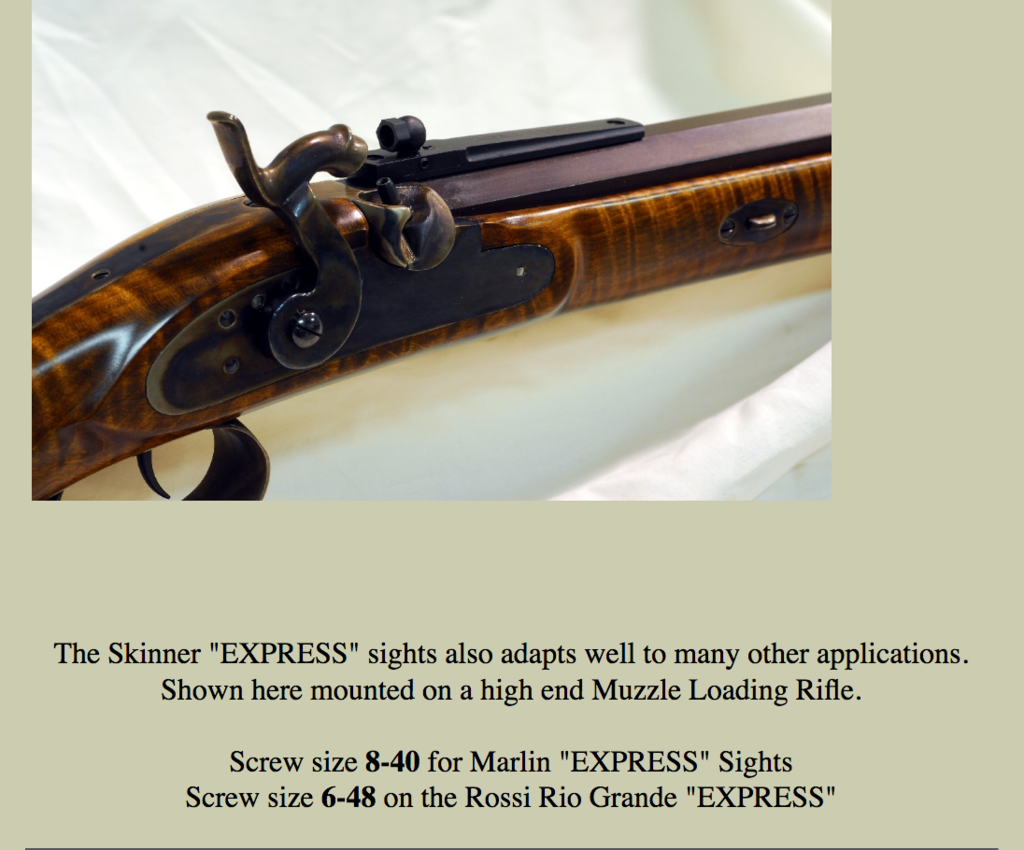

I put the Skinner Express sights on Betty's Marlin 1894CSS. Last picture. Also, put Skinner Brass front sight that is extra tall to file for sighting in.

Oh yeah, nice weather your having there in Texas. And, your making me hungry for some TexMex Barbecue!

I haven't gotten any shooting in here lately! Been thinning my gun collection down, giving to the young-uns in the family. I decided I've got way too many, and I want to see them being shot, used and appreciated before I croak! Besides, keeps them boys from asking Betty, "How's papaws health?" LOL

Grandson is Deputy Sheriff, Nephew is Indiana State Police Academy firearms instructor. Some of my tactical guns went to them. And some SASS fun guns as well. At this point in time, I really don't need enough guns and ammo to take out a banana republic!

I would contact Brownells if you decide to go with another Williams peep sight. They should be able to get you the right width for the factory dovetail. If you decide to go that route, you will need a dovetail file that is ground safe/flat on all but one side. Skinner sells these files as well. The sights should be slightly oversize (think .001" of inches here, not a lot). The way to do it is file only on one side of the barrel dovetail, going one light stroke at a time, and taking care to keep the stroke even. Check the fit, until the sight slides about 1/3 the way into the barrel dovetail by thumb pressure. If it goes that far, you should be able to tap it in with a brass hammer or plastic dead blow hammer, and finish with a brass punch the rest of the way in. At that point you should have enough of a press fit that you can adjust for windage with a brass punch if needed for sighting in. Another old trick is to center punch the flat of the dovetail if the sight is just slightly loose (or epoxy) you can heat it to make it soft again if need be to remove.

It is easy to do, if you take your time. I like to be in the right frame of mind for that job though. Not stressed, rushed, pissed off, agitated, angst or grumpy! Hey, I still have days I'm not like any of that!

If you don't have a drill press and the taps and you want to take advantage of F.G. Fords offer to fix your spoon sight for height adjustment that would work.

Also, Skinner Sights has screw in peep sight that you could drill and tap the spoon hole for, that way you can change peeps from Ghost sight to, small hole for fine target shooting. Click on the link below for

more info.

http://www.skinnersights.com/apertures_8.html

You would have to use a nut on the other side of the spoon since the spoon is so thin, and lock-tite of course. You have a ton of options here.

Another thought is low temp silver solder from Brownells. I'm impressed with the groupings your getting at 80 yards, so if you decide "if it ain't broke, don't fix it" that works for me too! I like the silver spoon with the built in engraving. Looks pretty cool to me! Bit of a large blind spot with the size of the spoon end, compared to peep hole, but again. I can't give you any grief with those groupings, and if you shoot with both eyes open probably don't even see a blind spot.

You think outside the box GoWacky. I like that.

I put the Skinner Express sights on Betty's Marlin 1894CSS. Last picture. Also, put Skinner Brass front sight that is extra tall to file for sighting in.

Oh yeah, nice weather your having there in Texas. And, your making me hungry for some TexMex Barbecue!

I haven't gotten any shooting in here lately! Been thinning my gun collection down, giving to the young-uns in the family. I decided I've got way too many, and I want to see them being shot, used and appreciated before I croak! Besides, keeps them boys from asking Betty, "How's papaws health?" LOL

Grandson is Deputy Sheriff, Nephew is Indiana State Police Academy firearms instructor. Some of my tactical guns went to them. And some SASS fun guns as well. At this point in time, I really don't need enough guns and ammo to take out a banana republic!

Similar threads

- Replies

- 5

- Views

- 196

- Replies

- 17

- Views

- 750