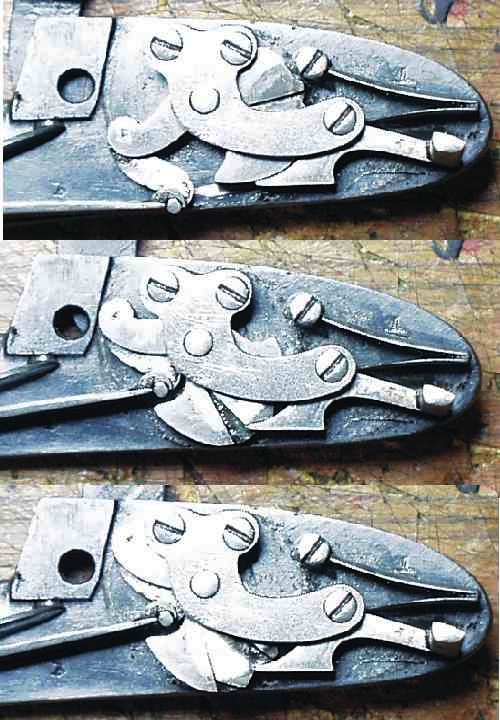

I don't know how to post a picture or I'd show you how I did one for my Charleville. One that would work well in your fusil, which I assume has a musket lock, though maybe a little smaller, is a piece of hardened steel about 3/8" long by about 1/4" wide and about 1/16" thick. It is rounded on both ends with flattened sides. You drill a hole (centered) near one end. This is for a pin about 1/16" diameter and about 3/16" long. You will need to mill a recess as deep as the fly is thick in your tumbler. I don't have any measurements handy, but the recess needs to be large enough to allow the fly to move enough to swing out of the way of the sear when setting it on half cock. The upper end of the recess needs to be near the spindle of the tumbler and a hole for the pin drilled near that end. Now, the figures I gave above are only approximate, as I don't have my lock in front of me and I believe my lock is bigger than yours anyway. Another type of fly such as come with Siler lock kits are cast with the fly and pin as one piece.

When you cock the piece to fire, the fly drags on the nose of the tumbler and when it clears it, it swings down in front of the half cock notch. When the trigger is squeezed, the tumbler is released and as it rotates the fly rotates with it and blocks the nose of the sear from catching in the notch. That's one of the reasons it is rounded on the ends. It allows the sear to slide by it. Only a small portion of the outer edge of the sear contacts the fly. The fly needs to be hardened somewhat so that the sear won't wear a notch in it.

I'm sure one of the moderators can post some good pictures that will detail what I'm talking about. I need to learn how to do that. Also, you need to get with a shooter who has a rifle with a fly, or better yet, a builder, and they can help you figure how big a recess to mill and the proper length for the fly. My Charleville would hang up if I squeezed the trigger and I had to jerk it to clear the notch which didn't help accuracy. I looked at how it was done on my rifle lock, allowed for a much bigger lock, crossed my fingers and started milling. It made a huge improvement. I hope this poor description helps a little.

How 'bout one of you Moderators post this feller a picture? It would have to be clearer than my description.

:: :results: :m2c: