- Joined

- Nov 26, 2005

- Messages

- 5,223

- Reaction score

- 10,882

Hi,

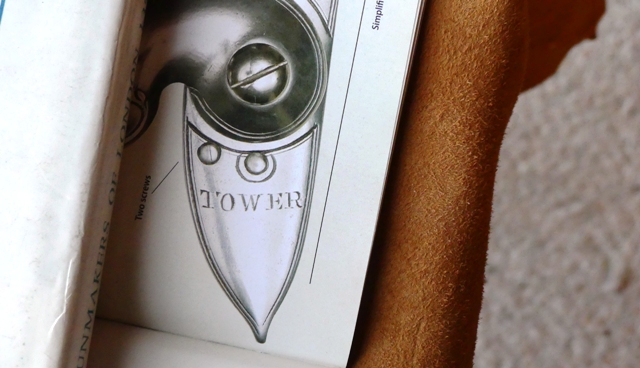

There was not a lot of cavalry action during our War for Independence on either side. The American army had very few mounted troops. Despite some special combined loyalist and British units like Tarleton's British Legion, only 2 British mounted units served in the war, the 16th and 17th light dragoons. Several historians believe the 16th was armed with pattern 1776 Royal Forester's carbines and the 17th with the pattern 1773 Elliot carbine. Both were very similar with the main difference being the Royal Forester's carbine had a more expensive flat faced lock whereas the Elliot mounted a typical round-faced carbine lock. My shop is tasked with making a carbine for a recreated unit of 17th light dragoons. The problem is that nobody has a clear idea of what the pattern 1773 Elliot carbine looked like in detail and one prominent author doesn't believe any Elliots were ever issued to British troops serving in America. Nonetheless, there are several surviving Elliot carbines with purported Rev War provenance but they all show great variation in details and several of them may have been altered during their service life. We were asked to build a carbine representing one used early in the war (1776-1778). My shop works closely with the collections at Fort Ticonderoga so our first job was to visit the Pell Research Center at Fort Ti and examine any examples in their collection. Our research at Fort Ti and other collections convinced us that the pattern 1773 Elliot was issued and present in America. However, none of the surviving examples of which we know shows unambiguous features indicating use during the early part of the war. Most have locks and other details that could only be produced late in the war or even after the Rev War. We are using a stock and components made by the Rifle Shoppe, however, they represent Elliot carbines from the late 18th century or early 19th. For example, the marking's on the lock plate were clearly stamped like later India pattern Brown Besses. The marks on a real pattern 1773 lock plate from an early Rev War carbine would be engraved. So there is much remedial work to do with the parts set. Anyway, here is the beginning of the project showing Maria inletting the barrel lugs.

We already built the lock and fitted the barrel. As usual, we strengthened the barrel channel with a varnish thin coat of AcraGlas. The ramrod hole in the fore stock was routed from the bottom of the barrel channel so we glued in a strip of wood to cover the slot and then applied the AcraGlas. Inletting the barrel tang was a nightmare because TRS cuts the apron around the tang. What happens it when you stab downward to cut in the side of the tang mortise, the outside of the apron cracks away because it has little wood to support it. I wish TRS simply would not cut the apron. Leave the excess wood in place and let the maker cut the apron. It would not be a problem if the wood was English walnut or maple but the black walnut used by TRS just does not have the density or strength.

The lock plate is in and the we made the sideplate. The one included in the parts set is copied from the Royal Forester's carbine and is found on later Elliot carbines. However, early Rev War carbines may have had scaled down pattern 1769 short land musket sideplates. So we made one from sheet brass.

It is not simple because it also has to be able to attach the side sling bar.

Here is the side plate provided by TRS and it is copied from the Royal Forester's carbine. Some late 18th century Elliot carbines used the side plate as well but it is unclear what the early guns used other than one example with a short and pattern musket side plate.

The Elliot has an effective way to prevent the ramrod from sliding out while bouncing around on horse back. The swelled portion behind the tip has a groove, which catches the end of a groove in the nose cap. The ramrod catches the lip of the nose cap and is secured in the stock until needed.

More to come,

dave

There was not a lot of cavalry action during our War for Independence on either side. The American army had very few mounted troops. Despite some special combined loyalist and British units like Tarleton's British Legion, only 2 British mounted units served in the war, the 16th and 17th light dragoons. Several historians believe the 16th was armed with pattern 1776 Royal Forester's carbines and the 17th with the pattern 1773 Elliot carbine. Both were very similar with the main difference being the Royal Forester's carbine had a more expensive flat faced lock whereas the Elliot mounted a typical round-faced carbine lock. My shop is tasked with making a carbine for a recreated unit of 17th light dragoons. The problem is that nobody has a clear idea of what the pattern 1773 Elliot carbine looked like in detail and one prominent author doesn't believe any Elliots were ever issued to British troops serving in America. Nonetheless, there are several surviving Elliot carbines with purported Rev War provenance but they all show great variation in details and several of them may have been altered during their service life. We were asked to build a carbine representing one used early in the war (1776-1778). My shop works closely with the collections at Fort Ticonderoga so our first job was to visit the Pell Research Center at Fort Ti and examine any examples in their collection. Our research at Fort Ti and other collections convinced us that the pattern 1773 Elliot was issued and present in America. However, none of the surviving examples of which we know shows unambiguous features indicating use during the early part of the war. Most have locks and other details that could only be produced late in the war or even after the Rev War. We are using a stock and components made by the Rifle Shoppe, however, they represent Elliot carbines from the late 18th century or early 19th. For example, the marking's on the lock plate were clearly stamped like later India pattern Brown Besses. The marks on a real pattern 1773 lock plate from an early Rev War carbine would be engraved. So there is much remedial work to do with the parts set. Anyway, here is the beginning of the project showing Maria inletting the barrel lugs.

We already built the lock and fitted the barrel. As usual, we strengthened the barrel channel with a varnish thin coat of AcraGlas. The ramrod hole in the fore stock was routed from the bottom of the barrel channel so we glued in a strip of wood to cover the slot and then applied the AcraGlas. Inletting the barrel tang was a nightmare because TRS cuts the apron around the tang. What happens it when you stab downward to cut in the side of the tang mortise, the outside of the apron cracks away because it has little wood to support it. I wish TRS simply would not cut the apron. Leave the excess wood in place and let the maker cut the apron. It would not be a problem if the wood was English walnut or maple but the black walnut used by TRS just does not have the density or strength.

The lock plate is in and the we made the sideplate. The one included in the parts set is copied from the Royal Forester's carbine and is found on later Elliot carbines. However, early Rev War carbines may have had scaled down pattern 1769 short land musket sideplates. So we made one from sheet brass.

It is not simple because it also has to be able to attach the side sling bar.

Here is the side plate provided by TRS and it is copied from the Royal Forester's carbine. Some late 18th century Elliot carbines used the side plate as well but it is unclear what the early guns used other than one example with a short and pattern musket side plate.

The Elliot has an effective way to prevent the ramrod from sliding out while bouncing around on horse back. The swelled portion behind the tip has a groove, which catches the end of a groove in the nose cap. The ramrod catches the lip of the nose cap and is secured in the stock until needed.

More to come,

dave