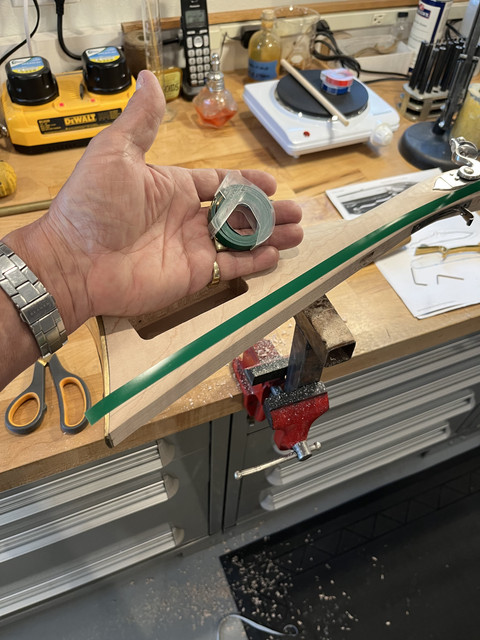

One thing I forgot to take pictures of when I was shaping the butt area around the cheek piece.....for the first time I used this.....

Like a computer, this angle grinder, with a 36 grit disk, will allow one to screw things up at the speed of light. However, I hate removing the wood on the cheek piece side in slow motion with chisels so I thought I would try this method. It worked great to rapidly remove a lot of unwanted wood and get me very close to a surface that did not take much additional wood removal with a small spoke shave and scrapers to get this.....besides, I am old enough where I can't afford to move too slowly. Eight bells might call me out before I get the next rifle done...

So....on with a little more peripheral carving while trying to decide on some major carving issues....Using the same technique as the molding on the lower edge of the butt, I ran a molding bead along the fore stock upper edge from the lock beaver tail to the rear ram rod pipe.

I also took a whack at a sketch of the carving around the barrel breach tang.....Haven't decided if i like it yet....

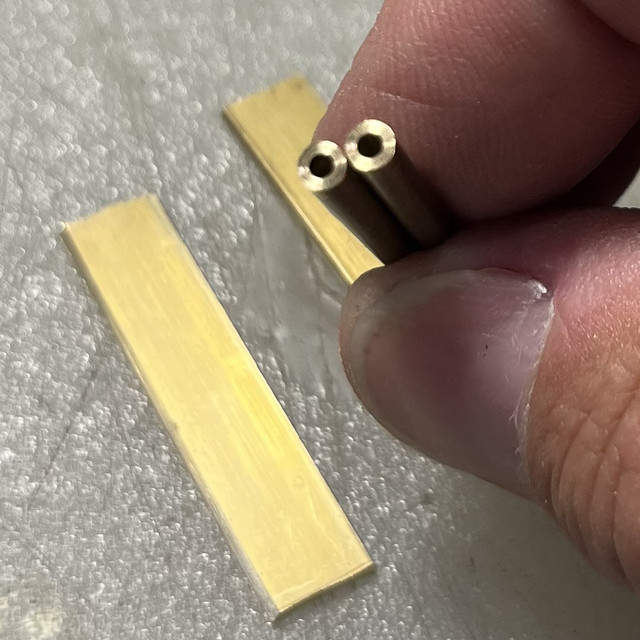

While I am deciding, I made up the hinge for the patch box. In other posts I have explained how and why I do this, b ut is has become my usual method for making a patch box hinge and is, to me, much simpler and less trouble than bending the knuckles out of the box plates themselves. First step is the take two pieces of 1/8" brass rod and drill them lengthwise with a 1/16" through hole, and then cut two pieces of 1/16" thick pieces of brass plate ~ 3/8" wide and 1 1/2" long.

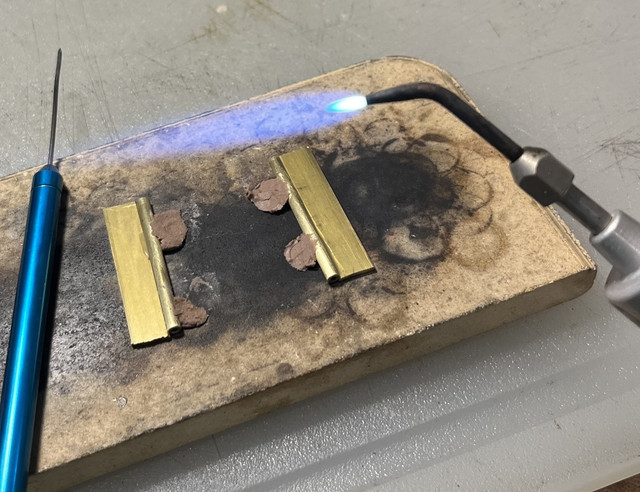

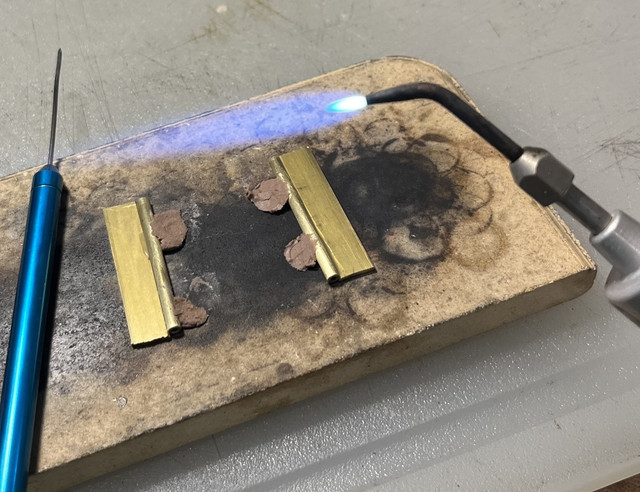

The two rods are then silver brazed to the edges of the plates....

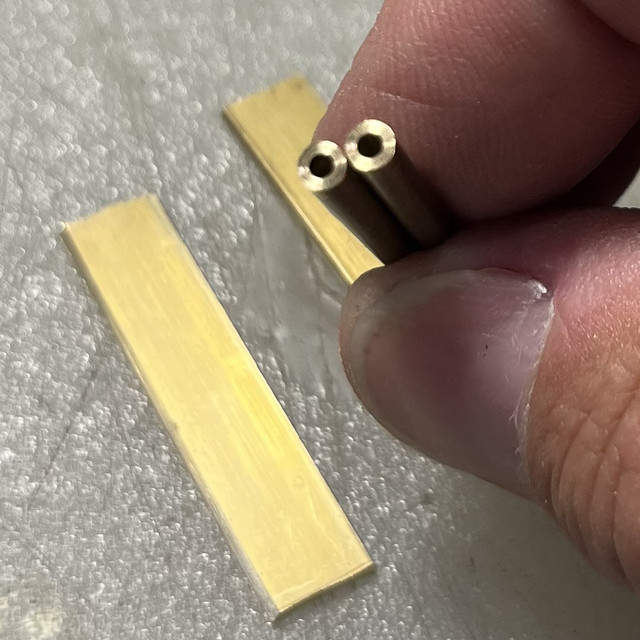

Acid pickled and cleaned up......

Cutting and filing the knuckles.......

Finished hinge. I will show later how this hinge is prepared for and attached to the box parts in a historically correct manner.