So I have had this gun for about 30 years. It used to have such a great dual set trigger Back story here. I sourced a new stock and .54 barrel Ever since the rebuild I just cant get the trigger right. I keep coming back to it from time to time with the same results no progress made. The trigger is just mushy with no wall and so light its un-usable for hunting. Its just plain mushy with no wall or break. The trigger is drop safe when set but releases at about 4 ounces with break with no wall just mush. The lock seems to be fine as it takes quite a bit of pressure to get it to fire. With the trigger in or out of the gun remains the same no matter how it is adjusted. I've gone as far as adjusting it till it won't set and operate to the other extreme to where it will set but won't release. There is just no sweet spot to get the travel out and a trigger over 4 ounces. Short of sourcing a new trigger I'm plumb out of ideas.

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My CVA Hawken Trigger Woes!

- Thread starter Icemanxxxv

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

What is the distance from the single trigger pivot point to the sear bar?

I maybe a bit slow on the uptake here, so bear with me. Are we talking about the release trigger to lock sear bar? I'm a bit confused by what you are asking. Are we talking about how far the release trigger is from the lock sear bar? Sorry I'm a bit confused. I was playing with the trigger the other night. It appears to me that once the trigger is set. The catch portion of the release trigger is just barely hanging on to the trigger bar. The best I could do was 14 oz. Average over 5 pulls. I did this 3 or 4 times with the same results within .2 of an ounce.What is the distance from the single trigger pivot point to the sear bar?

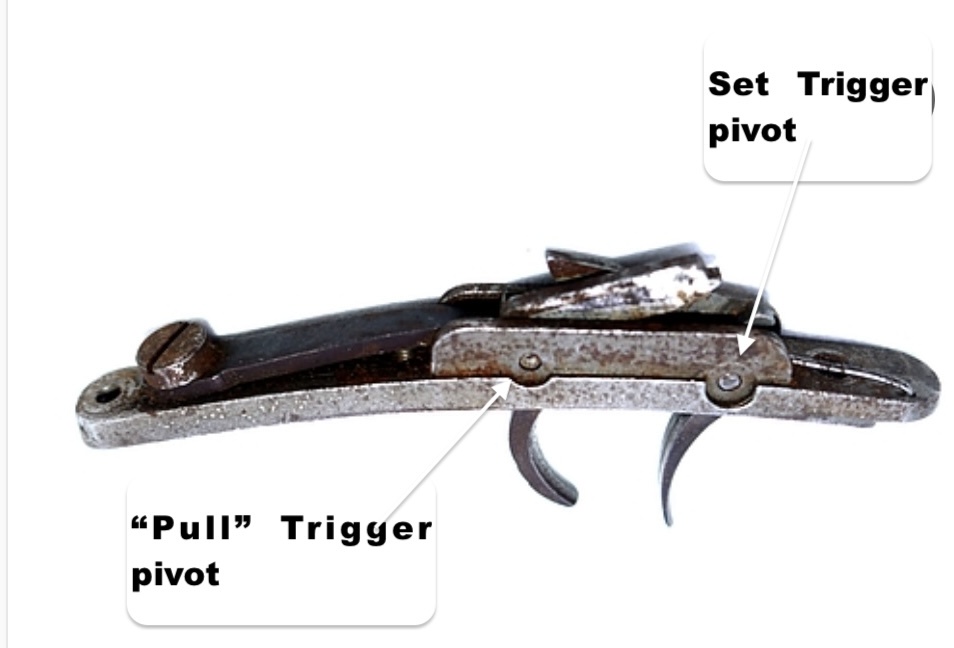

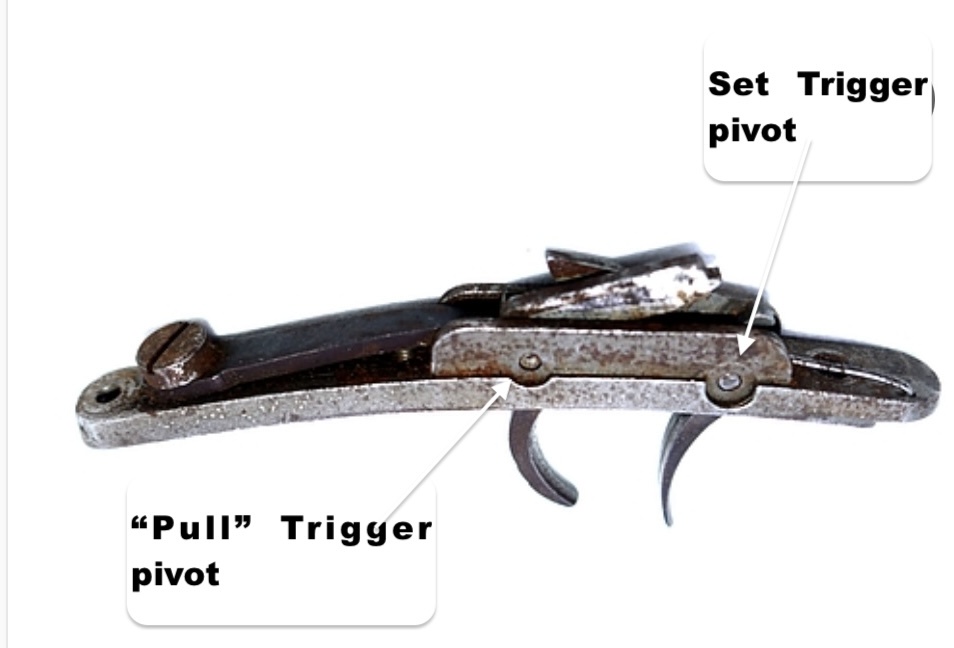

Both the set trigger, and the "pull" trigger have pivots. The pivot pin is what I'm speaking of and specifically the pivot pin of the "Trigger you pull to make it go BANG". (AKA the Pull trigger). How far from the locks sear bar is the pull trigger pivot point?

Since you stated you changed stocks I'm thinking this distance was changed when compared to the original placement in the factory stock.

Here's a quote from Jim Kibler on the subject of triggers:

"This is all very simple. Extend the trigger pivot distance as far as possible such that a desired pull can be achieved. This minimizes trigger travel to release the sear. A light pull and short trigger travel are desirable. With a proper lock, you can easily have. 2.5 pound pull with a short trigger travel with a 5/8” pivot distance. By shortening the distance to 5/16” you are effectively doubling the necessary travel to fire the lock. Not a good thing. This is elementary physics.

Why not just have a well set-up lock with a pivot distance of 5/8” or so and get the best of both worlds? Shortening the the pivot distance is a poor “fix” in my view.

It’s no wonder you see longer pivot distances on original work. Why these shorter distances became popular confuses me. Maybe to overcome lock problems…

As mentioned, I would be happy to help anyone with a heavier pull than they prefer to fix things properly."

Since you stated you changed stocks I'm thinking this distance was changed when compared to the original placement in the factory stock.

Here's a quote from Jim Kibler on the subject of triggers:

"This is all very simple. Extend the trigger pivot distance as far as possible such that a desired pull can be achieved. This minimizes trigger travel to release the sear. A light pull and short trigger travel are desirable. With a proper lock, you can easily have. 2.5 pound pull with a short trigger travel with a 5/8” pivot distance. By shortening the distance to 5/16” you are effectively doubling the necessary travel to fire the lock. Not a good thing. This is elementary physics.

Why not just have a well set-up lock with a pivot distance of 5/8” or so and get the best of both worlds? Shortening the the pivot distance is a poor “fix” in my view.

It’s no wonder you see longer pivot distances on original work. Why these shorter distances became popular confuses me. Maybe to overcome lock problems…

As mentioned, I would be happy to help anyone with a heavier pull than they prefer to fix things properly."

Last edited:

After trial and error tweeking the sear bar I have a reliable trigger at around 2 pounds. The crazy thing is if I set the trigger before cocking the hammer the trigger pull is about 5lbs to 7lbs

It's very difficult to analyze something like this with out pictures at a minimum, or actually having the piece. (Which I do not want)

From what you're telling me.....that if you set the trigger before cocking the hammer the pull lbs is increased. I'm thinking what that could be (or not) is the relationship between your sear bar and the contact point(s) of the trigger. When you set the trigger, all that should do is when you pull the regular trigger to fire, instead of the regular trigger engaging (hitting) the sear bar, the set trigger engages (hits) the sear bar. The set trigger is spring loaded so that energy causes the set trigger to "fly" up quickly and hit the sear bar.

So, if you set the trigger first, the **** the hammer....that seems to me that your trigger(s) may be binding against the sear bar when you set them first, then **** the hammer.

I would think if this is true, first set the trigger, then carefully look at the triggers when you **** the hammer. The triggers should not move. If you see movement, then the relationship between the triggers and the sear bar need looked at.

I'm not saying this is the issue, but it may be something to look at.

From what you're telling me.....that if you set the trigger before cocking the hammer the pull lbs is increased. I'm thinking what that could be (or not) is the relationship between your sear bar and the contact point(s) of the trigger. When you set the trigger, all that should do is when you pull the regular trigger to fire, instead of the regular trigger engaging (hitting) the sear bar, the set trigger engages (hits) the sear bar. The set trigger is spring loaded so that energy causes the set trigger to "fly" up quickly and hit the sear bar.

So, if you set the trigger first, the **** the hammer....that seems to me that your trigger(s) may be binding against the sear bar when you set them first, then **** the hammer.

I would think if this is true, first set the trigger, then carefully look at the triggers when you **** the hammer. The triggers should not move. If you see movement, then the relationship between the triggers and the sear bar need looked at.

I'm not saying this is the issue, but it may be something to look at.

Phil Coffins

69 Cal.

You should look at the set triggers as an independent device. With it out of the gun it must work in a clean crisp manner and be adjustable to your needs. That will require good materials, design, and finish. You have no control over the first two so stoning the engaging elements and lubricant any moving parts is where you can make a difference. Then deal with how it’s installed in the rifle.

Well I just broke the sear arm off my lock

It's my guess, but in your previous post stated you "tweeked" the sear bar. Sear bars are hardened and don't like to be filed, stoned, or twisted. If you twisted that sear bar previously, you likely cracked it. And if you tried to do that again, the result would be what you experienced.

Lock's are rather simple, but OTOH complex and need someone who understands them to make them right. I'd suggest you seek out a lock guy and get it fixed right. It may cost you a few bucks, but it's "fixed" forever.

Lock's are rather simple, but OTOH complex and need someone who understands them to make them right. I'd suggest you seek out a lock guy and get it fixed right. It may cost you a few bucks, but it's "fixed" forever.

It appears the Gun Works has CVA sears in stock. I'd call them to make sure which one fits your lock

https://thegunworks.com/shop/custom.../sear-right-big-bore-mtn-rifle-hunter-hawken/

https://thegunworks.com/shop/custom...ght-big-bore-hawken-mtn-frontier-and-shotgun/

https://thegunworks.com/shop/custom.../sear-right-big-bore-mtn-rifle-hunter-hawken/

https://thegunworks.com/shop/custom...ght-big-bore-hawken-mtn-frontier-and-shotgun/

In the process of fixing it now. Pretty sure it's not hardened steel more like a metal injected mould (MIM) part. Drilled way to easy for hardened steel. Maybe the sear surface was hardened. Anyhow i digress. I've got a request out for a sear from The Gun Works. Deer Creek has the newer style lock with the forward kock bolt that threads into bolster on the lock plate in stock. Pretty sure I can adapt that one. Option three is an L&R replacement. Pretty sure that option would be consistent with earnings on a  theme.

theme.

Gun works verified they had a sear in stock. In the mail Monday. 16 bucks and change shipped. Lessons learned.

Posting pictures of your existing broken sear and the new sear will be a huge help.

Sear replaced trigger works pretty darn good after inletting the stock a bit more.

Similar threads

- Replies

- 31

- Views

- 1K

- Replies

- 3

- Views

- 294