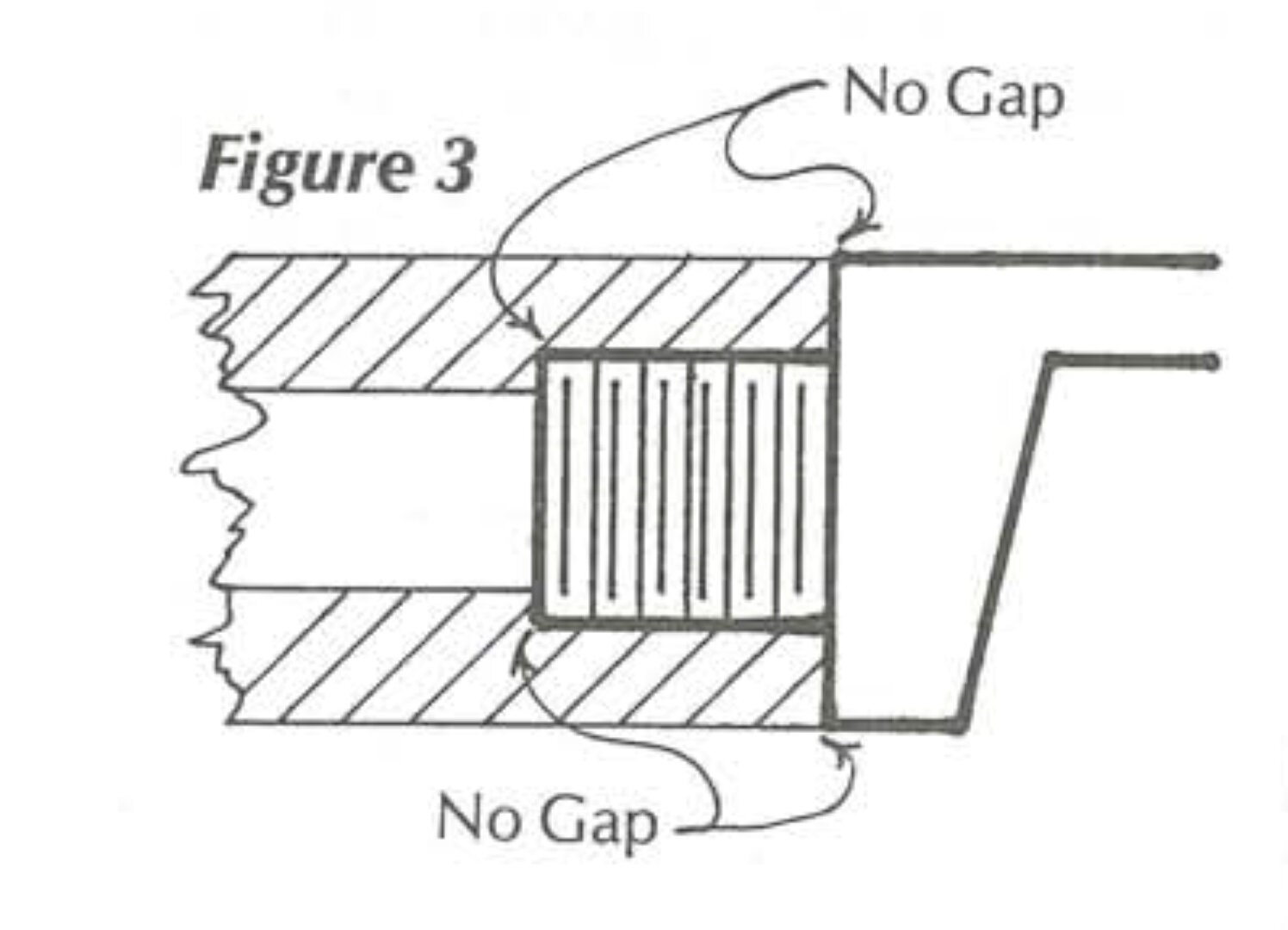

Your photo does not show the sholder in the barrel. The plug must seat on the counter bore sholder! Please see figure 3 from National Muzzleloading Association

Larry

Muzzle Loader Building,

Muzzleblasts,

Muzzle Blasts Archives

The Apprentice’s Notebook

Installing a Breechplug

By Jay T. Close, Kentucky

INTRODUCTION

A good measure of your rifle's safety, reliability and durability de pends in how the breech plug is installed. Fitting that plug is not a job to be taken lightly but it is how I usually begin a rifle. If I do a good job here, I can approach the rest of the rifle with confidence that the finished gun will be a safe one. If you're intimidated by this work, some manufacturers -- e.g. the Getz Co. -- sell barrels already breeched. You can be assured of this work. Also, if you buy a barrel and breech plug from Track of the Wolf, they'll install the plug for a modest charge. They too guarantee the work is done right. Nevertheless, the only way to learn to install a breech plug is to fit a few. Moreover, installing a breech plug is a very basic skill, certainly, one required of anyone aspiring to the appellation of "gunsmith". So, buy a barrel and a breech plug to match the barrel threads. You'll minimize frustration if you purchase one of the so-called premium barrels. These have the exterior of the barrel-shaped con centric to the bore and allow you to match the tang of the breech plug to any of the eight flats of the barrel.

GETTING STARTED

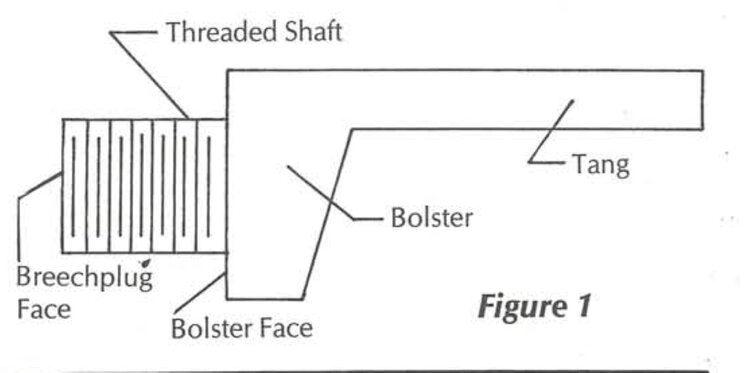

Figure 1 shows a schematic of a common breech plug with its various parts named. When you buy a barrel and breech plug make sure that the threads of the two components match. Be careful here because the threads used for various caliber barrels have not been standardized. The thread sizes employed by G. R. Douglas Co. in the past are fairly common so I'll list those below:

- .32 and .36caliber........9/16 x 18UNC

- .40 and .45 caliber........5/8x 18 UNC

- .50, .54 and .62 caliber.. ... 3/4 x 16 UNC

Also, make sure that the width of the breech- plug tang and height of the bolster will match the diameter of the octagon barrel you choose.

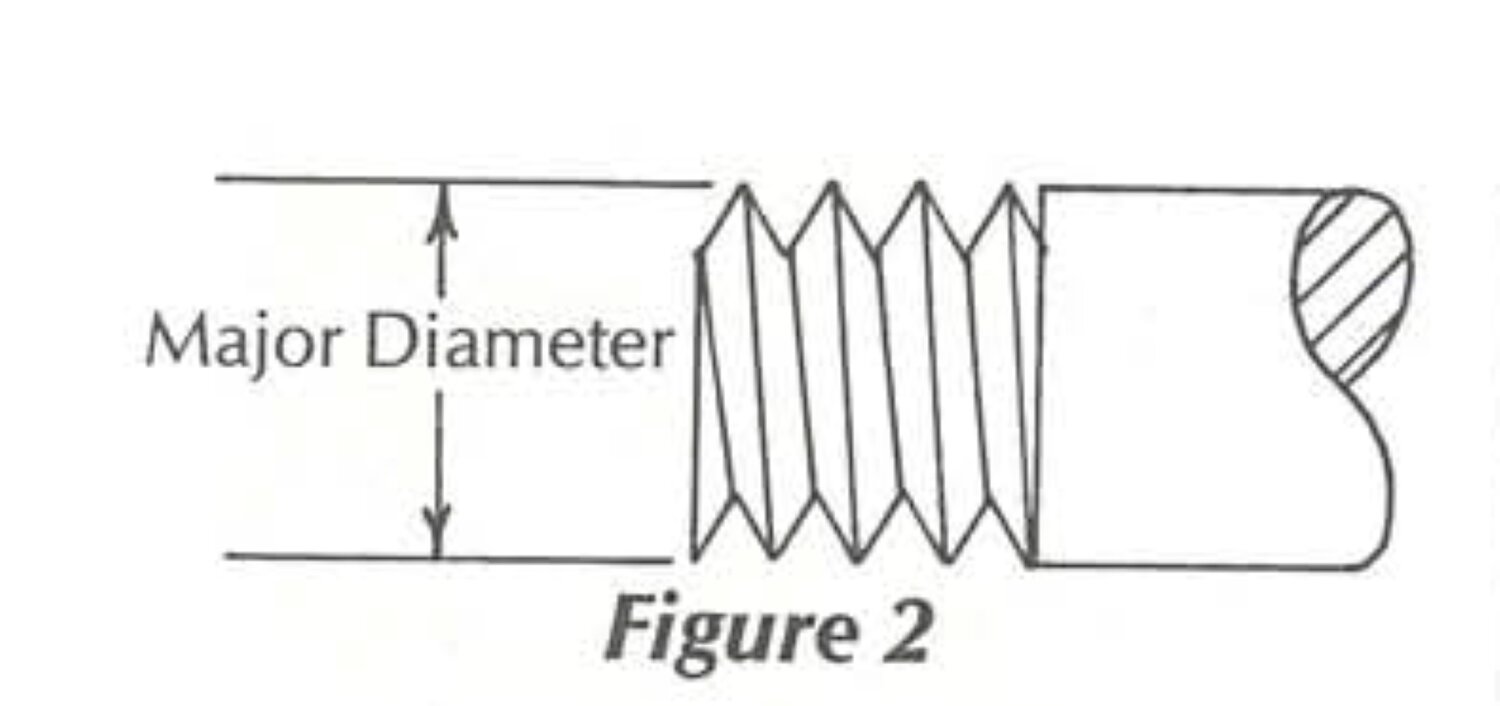

The height is most important, the width will fall into place. For those not familiar with the thread notes like "5/8 x 18 UNC" , I' ll try to explain. The "5/8" refers to the diameter of the threaded shaft, or the major diameter of the thread (Figure 2).

The number "18" tells the number of threads per lineal inch. You can have a threaded shaft 12 inches long or 1/2 inch long, but a 5/8 x 18 thread will still have 18 threads per inch. Eighteen threads per inch has a couple of consequences. First, to screw a 5/8 x 18 threaded shaft forward one full inch, the shaft will have to revolve 18 complete revolutions. Second, for each complete revolution, the shaft will move

forward (or back) 1/18 of an inch. A machinist or engineer would say the thread has a pitch of 1/8 inch or about .056 of an inch. This is all simple geometry and you can easily figure similar consequences for any known thread size.

Finally, "UNC" stands for Unified National Coarse. This is a standardized set of thread sizes rec oganized throughout the United States. Unified Nation Fine (UNF) is another common series in this country; and then, of course, metric threads....you can look that up for yourself! Seriously, there's a lot more to know about threads (e.g. class of fit, left hand threads, thread forms), but if you remember that the first number in a common thread note refers to the diameter of the threaded shaft and the second number to the threads per inch, you'll be in good shape.

To breech your barrel, you need to install the plug to fit three sur faces precisely. Most important for the safety of your rifle is the fit of the breechplug face. This must bottom tightly in the threaded portion of the barrel. Any gap there will collect powder fouling, harboring sparks and corrosion. See Figure 3.

Second, at the same time the face of the plug bottoms in the barrel threads, the face of thebolster must screw tightly to the back of the bar rel. Any gap here will be obvious on thefinished gun and detract from its appearance (Figure 3).