JOHN ZUREKI

36 Cal.

- Joined

- Feb 21, 2005

- Messages

- 61

- Reaction score

- 5

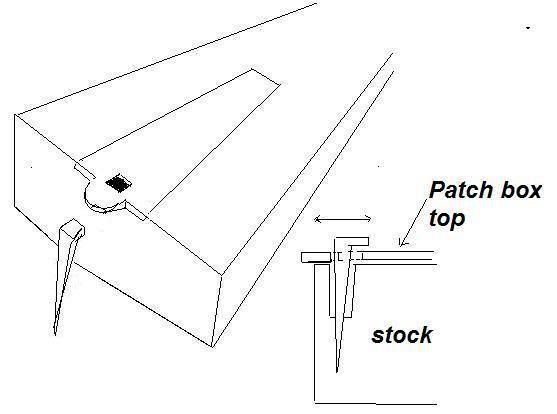

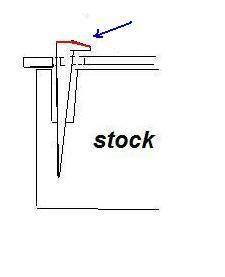

MR. MIKE BROOKS, I VERY MUCH ENJOYED YOUR TUTORIAL ON BUILDING FROM A BLANK. WHEN YOU WERE INSTALLING THE PATCH BOX, YOU MENTIONED THAT YOU WOULD IN THE FUTURE, EXPLAIN THE RELEASE THAT YOU USED ON THAT RIFLE. WOULD YOU BE SO KIND THAT WHEN YOU GET A CHANCE POST A PICTURE OF WHAT THE RELEASE LOOKS LIKE. THE BOX THAT I'M WORKING ON CALLS FOR SOMETHING OTHER THAN THE BUTTON AND ROD THRU THE COMB OF THE BUTT PLATE OR THE CAM OVER RELEASE ETC.... A SINGLE PICTURE WOULD A BIG HELP. THANK YOU VERY MUCH. JZ