-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

patent breach

- Thread starter bigmike

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The Blue Ridge has what people call a Patent Breech. But it isn't a true Patent Breech.

I have not disassembled my Blue Ridge but I have some TC's.

I think manufacturers use them because they can use the same barrel for either flint or percussion by just changing the breech plug.

Basically it is a chamber that is smaller than bore diameter. On a TC this smaller chamber is around .375 inch in a 50 cal. I understand the one Pedersoli uses on there’s is much smaller in diameter. This I have not seen and would only tend to believe certain people. Imagine that?

At any rate this Patent Breech on a TC is no issue at all and some say it is better. On Pedersoli's some say it is a problem because it is so small. I have never had an issue with mine. It shoots the way it is supposed to.

Don't worry about it but be aware of it.

I have not disassembled my Blue Ridge but I have some TC's.

I think manufacturers use them because they can use the same barrel for either flint or percussion by just changing the breech plug.

Basically it is a chamber that is smaller than bore diameter. On a TC this smaller chamber is around .375 inch in a 50 cal. I understand the one Pedersoli uses on there’s is much smaller in diameter. This I have not seen and would only tend to believe certain people. Imagine that?

At any rate this Patent Breech on a TC is no issue at all and some say it is better. On Pedersoli's some say it is a problem because it is so small. I have never had an issue with mine. It shoots the way it is supposed to.

Don't worry about it but be aware of it.

Here is drawing (not to scale) that will give you the idea of the patent breach.

I've found several British gun makers with their own take on the design and each claims to have a patent. Many drilled the channel from the touch hole completely through the barrel and put a plug in the opposite side. Some drilled this area of the breach plug in a larger size than the touch hole and used what we call a liner to reduce the touch hole to proper size.

One issue I've run into with modern patent breaches is the manufacturers seem to have one design for their larger caliber guns which they just scale down for smaller calibers this scaling results in the diameter from the breach to the false breach being reduce to a size that will not allow powder to travel from the false breach into the breach if there is a lot of humidity or the air is cold. (The humidity condenses on walls of this channel and the powder granules stick to this condensation and form a plug.) The temporary solution is to work priming powder (FFFFg) through the touch hole into the breach so it can set off the main charge trapped in the false breach. The permanent solution is to remove the breach and drill out this channel to larger size so it can't be plugged up with powder regardless of the weather.

I've found several British gun makers with their own take on the design and each claims to have a patent. Many drilled the channel from the touch hole completely through the barrel and put a plug in the opposite side. Some drilled this area of the breach plug in a larger size than the touch hole and used what we call a liner to reduce the touch hole to proper size.

One issue I've run into with modern patent breaches is the manufacturers seem to have one design for their larger caliber guns which they just scale down for smaller calibers this scaling results in the diameter from the breach to the false breach being reduce to a size that will not allow powder to travel from the false breach into the breach if there is a lot of humidity or the air is cold. (The humidity condenses on walls of this channel and the powder granules stick to this condensation and form a plug.) The temporary solution is to work priming powder (FFFFg) through the touch hole into the breach so it can set off the main charge trapped in the false breach. The permanent solution is to remove the breach and drill out this channel to larger size so it can't be plugged up with powder regardless of the weather.

Sir Michael said:Here is drawing (not to scale) that will give you the idea of the patent breach.

I've found several British gun makers with their own take on the design and each claims to have a patent. Many drilled the channel from the touch hole completely through the barrel and put a plug in the opposite side. Some drilled this area of the breach plug in a larger size than the touch hole and used what we call a liner to reduce the touch hole to proper size.

One issue I've run into with modern patent breaches is the manufacturers seem to have one design for their larger caliber guns which they just scale down for smaller calibers this scaling results in the diameter from the breach to the false breach being reduce to a size that will not allow powder to travel from the false breach into the breach if there is a lot of humidity or the air is cold. (The humidity condenses on walls of this channel and the powder granules stick to this condensation and form a plug.) The temporary solution is to work priming powder (FFFFg) through the touch hole into the breach so it can set off the main charge trapped in the false breach. The permanent solution is to remove the breach and drill out this channel to larger size so it can't be plugged up with powder regardless of the weather.

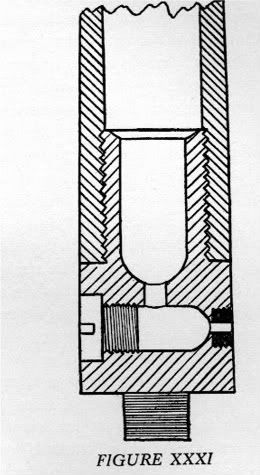

This is a Nock. I have been told in England its the only patent breech.

There are others. Few percussions look and this and I know of no Nock breeches other than on custom guns. They are not, so far as I know available other wise.

The Nock will not work with low grade powder. At least mine does not and it has a .175 hole to the antechamber.

I have never had a problem with Swiss. Even if blowing in the bore the dampen the fouling.

These are plain breeches from my 50 cal Swivel and these are simply drilled back to allow a vent to be drilled into the powder chamber.

This is the percussion patent breech from a Browning Mountain Rifle.

Its the only percussion I have a photo of. Its not a particularly good percussion breech threads too long and its cross drilled and the hole plugged to give nipple flash access to the powder.

The best of them have a shorter threaded shank and are drilled at an angle to the base of the nipple. Track of The Wolf calls this "direct drilled" I believe.

Since these are invariably hooked to allow quick removal of the barrel for cleaning by submerging the breech in a container of water or pouring water through without wetting the stock.

My Nock breech cleans up very easily in this manner and the antechamber is always spotless the random times I pull the left side plug to check it.

Dan

i hate the "patent breech" on my pedersoli long rifle. its extremely prone to fouling and required that i develop a system to fire the gun reliably.

if i swab the gun even a single time while shooting i must fire off a cap without powder to clear the breech path or the gun will not work with powder and ball.

i love my guns that do not have this "patent breech". while they do tend to build up some serious fouling, they are much easier to clean out and have been more reliable for me.

if i swab the gun even a single time while shooting i must fire off a cap without powder to clear the breech path or the gun will not work with powder and ball.

i love my guns that do not have this "patent breech". while they do tend to build up some serious fouling, they are much easier to clean out and have been more reliable for me.

- Joined

- Jun 12, 2005

- Messages

- 7,995

- Reaction score

- 1,003

Mt T/C flinter has what you might call a patent breech, and it's never been hard to clean- although i do occasionally run a .22 brush into the skinny section to scoop out the 'crud.' Usually i gert nothing, 'cause i shoot real BP and it all comes out with the warm soapy water method.

Good luck with your new rifle!

make good smoke!

Good luck with your new rifle!

make good smoke!

Run a .38 brush instead. You might get more.

Personally, I avoid brushes in muzzleloaders.

Personally, I avoid brushes in muzzleloaders.

Matt85 said:i hate the "patent breech" on my pedersoli long rifle. its extremely prone to fouling and required that i develop a system to fire the gun reliably.

if i swab the gun even a single time while shooting i must fire off a cap without powder to clear the breech path or the gun will not work with powder and ball.

i love my guns that do not have this "patent breech". while they do tend to build up some serious fouling, they are much easier to clean out and have been more reliable for me.

Try using a somewhat smaller jag, put one in a drill and spin it against a file to reduce the diameter, trying the fit as you go. Too small and it may lose the patch in the bore. For a 45 for example you need a jag that is about 2/3s to 3/4 of the way between 40 and 45. Use a somewhat larger dimension cleaning patch not too wet, less than dripping but uniformly wet, heavily damp is a good description. I wet them at least the night before using them and do them is batches of 40-50 at a time.

The loose patch will slide over much of the fouling but will bunch up with pulled back up and bring more fouling out. I do this once each side. Then a dry patch once each side.

The patch not being too wet does not run water into the reduced diameter part of the breech and the looser patch does not jam all the fouling in the bore into the breech.

I also use this loser fit with a water slosh (plugged vent or sealed nipple) for the first couple of passes when cleaning a barrel in the rifle, fixed breech type as most of mine are. Then go to a tighter jag for the rest of the cleaning.

Many of the breech designs are made to be easy to produce not necessarily for optimum ignition.

I have a friend with a rifle I made that has ignition problems and we need to pull the breech and look at it. Its a direct drilled Hawken type from TOW. I was surprised that he has problems with it. Will have to watch him wipe between shots but he is VERY experienced this is why I wonder what the heck is going on.

My 50 Swivel with 3/8" recess back to the vent location if wiped as I describe will shot 20 shots with no problem so long as I make sure the vent is clear. My cupped breech 50 will give problems if the patches are too wet. It has a cup in the breech face with the vent near the bottom of the cup to get the lock fence where it needed to be for the rifle I was using as a guide.

The wiping method may help, may not but it is worth a shot.

Dan

robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 20

Henry Nock's patent breech was an accidental improvement for shotguns. Zeke Baker claims to have given him the idea for the fancy curve behind the powder but Zeke never used it on his rifles because it was undesirable.

The problem they had with shotguns was they had no cartridge end to roll over and delay the shot until the pressure built up. That roll counts for a lot with BP shells and they couldn't do it.

The patent breech was supposed to focus the explosion, what it actually did was provide a separate chamber where it was impossible to compress the powder when ramming down. The loose powder detonates and lights the whole of the main charge so the pressure builds much faster. Not really desirable on a rifle because you don't want to strip the ball.

It was good for shotguns though, bore sizes increased and barrels shortened.

The problem they had with shotguns was they had no cartridge end to roll over and delay the shot until the pressure built up. That roll counts for a lot with BP shells and they couldn't do it.

The patent breech was supposed to focus the explosion, what it actually did was provide a separate chamber where it was impossible to compress the powder when ramming down. The loose powder detonates and lights the whole of the main charge so the pressure builds much faster. Not really desirable on a rifle because you don't want to strip the ball.

It was good for shotguns though, bore sizes increased and barrels shortened.

I have suffered through several noch-patent breeches and got rid of them and replaced them with plain breeches.Happy to hear they improve shotguns.At some time it must have been thought that putting the fire into the center of the charge would improve ignition in rifles,maybe it does but any improvement is offset by the cleaning and firing problems IMHO.

Squire Robin said:Henry Nock's patent breech was an accidental improvement for shotguns. Zeke Baker claims to have given him the idea for the fancy curve behind the powder but Zeke never used it on his rifles because it was undesirable.

The problem they had with shotguns was they had no cartridge end to roll over and delay the shot until the pressure built up. That roll counts for a lot with BP shells and they couldn't do it.

The patent breech was supposed to focus the explosion, what it actually did was provide a separate chamber where it was impossible to compress the powder when ramming down. The loose powder detonates and lights the whole of the main charge so the pressure builds much faster. Not really desirable on a rifle because you don't want to strip the ball.

It was good for shotguns though, bore sizes increased and barrels shortened.

Other than recoil I have yet to find a downside to the Nock breech in my 67 caliber rifle.

It fouls very little with 140 gr of FF Swiss.

Never damages a patch. Shoots as well as I could want.

But it does kick.

Click on the image.

Could be that with small bores or lighter charges there might be a problem.

Dan

- Joined

- Mar 16, 2007

- Messages

- 542

- Reaction score

- 52

That sort of reminds me of the, "Any landing that you can walk away from is a good one." school of shooting.

- Joined

- Jan 31, 2009

- Messages

- 12,721

- Reaction score

- 6,848

Had a Traditions .36 rebored a while back to use .451 round ball and reworked the breech at the same time. Now a smaller sized brush or jag isn't needed and it isn't prone to post-swabbing failure to go boom. Huge improvement.

Thank you Mr. Hoyt.

Thank you Mr. Hoyt.

robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 20

Hi Dan

Neat movie :hatsoff:

I think Baker had problems with his patches that you won't get with modern rifling. No reason to suppose that a patent breech isn't good for your gun.

best

Robin

Neat movie :hatsoff:

I think Baker had problems with his patches that you won't get with modern rifling. No reason to suppose that a patent breech isn't good for your gun.

best

Robin

I've made home made patent breeches on percussion guns with 13/16ths inch barrels with a drum. Not much metal to screw a drum in for my tastes. So I drill the end of the breechplug with a 5/16ths hole around the same depth and locate the drum from the side to instersect into this communication hole. Have to place the barrel farther forward to do this. That way I get full drum thread engagement through the barrel and into the breechplug to intersect the firing chamber. It takes an extra step in final cleaning to swab out the small chamber, but I'll swear a 13/16ths barrel flat doesnt seem thick enough to screw a drum into. OOPS I"m in the flintlock section.

Bob

Bob

This is Pedersoli's version of what Leatherbark describes. The plug is extra long and the vent liner or percussion drum is threaded through the barrel and into the plug. The powder chamber in the face of the plug is only .22 caliber, which is why they tend to misfire after a bit of fouling builds up and especially if you get any moisture down there. I think at least some CVA's are similar.

Squire Robin said:Hi Dan

Neat movie :hatsoff:

I think Baker had problems with his patches that you won't get with modern rifling. No reason to suppose that a patent breech isn't good for your gun.

best

Robin

This is something "moderns" often overlook. Some of the rifling forms of the 19th century caused problems that we, generally, don't have today.

I have often wondered about the rifles Forsythe had made and what the rifling forms and number of grooves were.

I have a friend with a Green River IIRC 69 caliber barrel with a 1:56 twist that causes him no problems with charges over 180 gr.

While this is not as fast as some English Rifles of the time its still faster than Forsythe would have recommended. I often wonder if Forsythe went overboard with his slow twists.

I do know that the Nock Breech does not work well with low quality powder.

Dan

I shoot a .50 Pedersoli Blue Ridge flintlock and haven't had any problems with fouling causing misfires. I do use a slightly undersize jag between shots and that seems to allow the moist patch to catch and absorb the fouling rather than jam it down against the hole in the breech plug.

I've tried the .22 jag for cleaning the port but have found that one of the CVA breech cleaner "pipecleaners" run through the touch hole opening followed by a blast of compressed air takes care of things.

Like the Pedersoli because of the extra large frizzen...sparks good. And the rifle is easy to take down to clean and it's light enough for an older man to handle comfortably.

I've tried the .22 jag for cleaning the port but have found that one of the CVA breech cleaner "pipecleaners" run through the touch hole opening followed by a blast of compressed air takes care of things.

Like the Pedersoli because of the extra large frizzen...sparks good. And the rifle is easy to take down to clean and it's light enough for an older man to handle comfortably.

Dan Phariss said:69 caliber barrel with a 1:56 twist that causes him no problems with charges over 180 gr.

holy cra....!

sorry to drag us off topic but 180 grains of powder under a 69 cal projectile sounds like trying to shoot a howetzer from the shoulder! i cant imagine the level of pain and bruising this would cause...

i fired a patched .685 ball over 90 grains of 2F out of my 1842 rifled musket once. the recoil was on par with a 12 gauge 3 1/2" magnum buckshot load outa a short barreled mossberg... i will never do either of those again!

Joel/Calgary

50 Cal.

- Joined

- Oct 19, 2004

- Messages

- 1,251

- Reaction score

- 6

Dan do you actually have a Nock type breech with the transverse chamber and rather tiny hole connecting forward, or is it a Manton type in-line chamber with the touch-hole just connecting into the bottom, like most of the modern-production flint (and percussion) patent breeches?Dan Phariss said:Other than recoil I have yet to find a downside to the Nock breech in my 67 caliber rifle.

Regards,

Joel

Similar threads

- Replies

- 0

- Views

- 346