I have a cva barrel on a hand made custom full stock. the rife had a cva lock, but I had the local gun Smith install a l&r rpl lock. he adjusted the angle of the powder drum so there was a better nipple alignment. the drum has notches so a wrench can turn it. after shooting I cleaned it. I poured water down the barrel and when I swab the bore water pushed out between the drum and barrel. it has never done this before. what can I do to fix this. I don't want to take it back because the gunsmith took for ever, and did not do a good job. there is a small gap on top between the barrel and the drum.

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

powder drum not sealed

- Thread starter vega72

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

galamb

58 Cal.

If water can get out between the drum and the barrel that indicates the hole is probably too big for the drum that is in there.

I personally would not shoot this anymore until you have it checked out by someone "competent".

A poorly fitted nipple can exit from the side of the rifle at extremely high speed when you pull the trigger.

You could kill someone standing beside you.

A CVA factory drum was never meant to be removed. If someone "messed with it" you could have a whole can of worms on your hands.

Seriously - based on what you note this rifle is potentially very very dangerous - have it checked out...

I personally would not shoot this anymore until you have it checked out by someone "competent".

A poorly fitted nipple can exit from the side of the rifle at extremely high speed when you pull the trigger.

You could kill someone standing beside you.

A CVA factory drum was never meant to be removed. If someone "messed with it" you could have a whole can of worms on your hands.

Seriously - based on what you note this rifle is potentially very very dangerous - have it checked out...

Bad gunsmithing from git-go.

You need a barrel replacement with a new, and properly fitted, drum.

BTW, IMHO, putting a CVA barrel on a custom rifle is like putting work boots on a sprinter. :shake:

Tough lesson.

You need a barrel replacement with a new, and properly fitted, drum.

BTW, IMHO, putting a CVA barrel on a custom rifle is like putting work boots on a sprinter. :shake:

Tough lesson.

if you saw the rifle you may think different. it has a real nice curly maple. the barrel is the older 33 inch cva barrel with 1-66 twist. it is very accurate, and shoots very nice groups. the barrel has a very nice patina and I get lots of complements from people at shoots. the only thing I did not like was the cva lock so I changed it to an l&r rpl lock. I did some more research and I took a wrench and turned the bolster (drum) a short turn back (tightend) to its original position. the cock still clears the nipple. the gunsmith maybe should have left it alone. I pressure checked it with water and a swab. it does not leak between the bolster and barrel. maybe being an older barrel the bolster screws out.

stinkyfeet

50 Cal.

- Joined

- Dec 3, 2012

- Messages

- 1,008

- Reaction score

- 1

The last used percussion gun I bought the drum was loose on and didn't line up correctly. I ended up taking it to my buddies machine shop and he turned down the thread on the drum a bit until it lined up properly when tightened. Now everything is great. I am glad ya figured yours out once its tightened after a few shots the pressure placed on it while shooting should lock it in place well, for good.

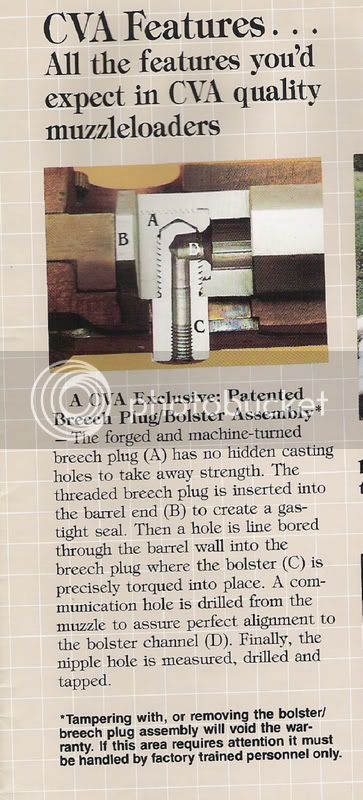

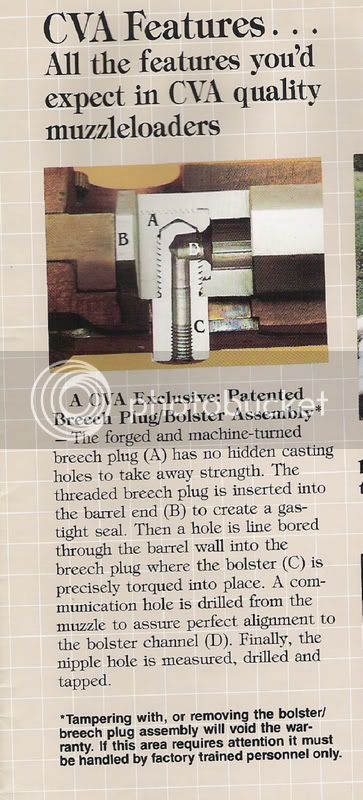

There will be someone soon who will hopefully post a picture of that actual drum barrel breech configuration. Or if you do a search you will find it here somewhere. When you look at it you will notice the drum goes all the way back into the other side of the breech plug. The front of the breech plug threads next to where the breech plug enters the barrel is not far from where the drum enters the barrel. This is where I always believed the water and gas leakage comes from. CVA probably had a sealant on the threads originally. When it was turned (and I'll bet he had to use heat)the seal was compromised. If he was able to move it, I would remove it all the way and use some red locktite or some kind of compound and put it back permanently.

Let me see if I can explain a little better by using random numbers.

The breechplug screws into the barrel say 1 inch. THe drum screws into the side of the barrel through the breech plug with the front of the drum threads about a 1/4 inch from the front of the breechplug and from the actual firing chamber. When someone posts that picture you will see that water and gas only has to wiggle by 4 or 5 threads and one turn to get out where the drum enters the barrel. I've seen a lot of CVA's with black fumes in this area from gas leakage.

Bob

Let me see if I can explain a little better by using random numbers.

The breechplug screws into the barrel say 1 inch. THe drum screws into the side of the barrel through the breech plug with the front of the drum threads about a 1/4 inch from the front of the breechplug and from the actual firing chamber. When someone posts that picture you will see that water and gas only has to wiggle by 4 or 5 threads and one turn to get out where the drum enters the barrel. I've seen a lot of CVA's with black fumes in this area from gas leakage.

Bob

I would bet the factory used some type of sealer on the threads. probably just like with an air hose you need something on the threads or the air leaks out. I bet someone out there got a wild idea to remove the breech plug and did not remove the bolster first, and really screwed things up. with the way cva designed the barrel that would probably ruin it.

This one?

As said, a lot of those leak. It seem's people just can't leave those things alone.

There's another forum out there that has 2-3 guy's that scream immediately their distain for this type of breech.

If and when they're messed with enough they will blow out, :idunno:

As said, a lot of those leak. It seem's people just can't leave those things alone.

There's another forum out there that has 2-3 guy's that scream immediately their distain for this type of breech.

If and when they're messed with enough they will blow out, :idunno:

vega72 said:if you saw the rifle you may think different. it has a real nice curly maple. the barrel is the older 33 inch cva barrel with 1-66 twist. it is very accurate, and shoots very nice groups. the barrel has a very nice patina and I get lots of complements from people at shoots. the only thing I did not like was the cva lock so I changed it to an l&r rpl lock. I did some more research and I took a wrench and turned the bolster (drum) a short turn back (tightend) to its original position. the cock still clears the nipple. the gunsmith maybe should have left it alone. I pressure checked it with water and a swab. it does not leak between the bolster and barrel. maybe being an older barrel the bolster screws out.

Sounds like a nice stock, and that is a good lock. But the leak and yer bubble gum and bailing wire fix :shake: on the drum still sounds potentially dangerous to me. :td: Good luck. Wear shooting glasses and don't shoot with anyone standing within a 100 yards to your right. :shocked2:

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 44

If it were my gun, I'd back out the bolster a few turns and apply the kind of Lok-Tite that you can break loose if you ever need to. Just a drop or two on the threads and then screw it back in until the nipple lines up with the hammer properly. If you do not actually remove the bolster, it will line up with the bore correctly when you turn it back in. The Lok-Tite will seal the threads and stop any gas leaks.

I had a CVA Mountain Rifle back in the 70's that developed a leaky drum. I tried brazing the drum to the barrel, but by the time I filed the brazing so the lock fit properly it would soon leak again. I returned the barrel to CVA and they sent me a new barrel. I turned around and traded it in on a new Lyman GPR.

- Joined

- Nov 10, 2005

- Messages

- 439

- Reaction score

- 46

Bottom line: the CVA breeching system is extremely strong and effective, but, as Necchi demonstrates, is not to be tinkered with. Too many kitchen table mechanics in our hobby think they are qualified gunsmiths and end up creating problems like this. Oh, and, by and large, the Spanish made barrels are of good quality and are very accurate shooters.

from the picture that was posted the threads go quite deep. unless the integrity of the threads have been compromised the system should be strong. I tightened it back to its original position, only a degree or two, and its tight.

I think it should be fine. test fire it with light loads and gradually increase them slowly and monitor for leakage. Gunsmith never should have messed with it, there are other ways to line up the hammer correctly. Usually those drums(CVA) are so tight you have to almost tear them up trying to turn them so I am surprised he was even able to turn it some.

rafterob

62 Cal.

I have to assume that turning it some to line up the nipple was a very minimal amount. My biggest concern here is that the pilot hole drilled in that drums shaft does not now line up fully with the powder chamber. Again, probably not a huge deal. As mentioned the shaft of that drum goes all the way accross the barrel into the opposite side so a few degrees turn of the drum isn't going to suddenly weaken the whole deal. The suggestion of backing it out some and applying locktite or antiseize is not a bad idea. I had a slightly leaky drum on my mountain rifle which has self-sealed after years of use. You have to be very careful when attempting to remove those drums. I snapped one off once, and many others have done the same thing.

I removed mine once so I could do a flint conversion. It took allot of force and I screwed it up abit bit that didn't matter since I didn't need it any more with the flint conversion.

don hepler

58 Cal.

- Joined

- Nov 19, 2010

- Messages

- 2,260

- Reaction score

- 10

Sounds like the gunsmith, was unaware of how the bolster is torqued, and drilled thou the muzzle to create the necessary alignment. He probably took the easy way out by turning the bolster, rather than bending the nose of the hammer, in order to achieve the alignment necessary for the hammer to strike the nipple, squarely.

I think, I would be looking for an experienced smith used to working on black powder firearms.

I think, I would be looking for an experienced smith used to working on black powder firearms.

The suggestion of backing it out some and applying locktite or antiseize is not a bad idea.

:shocked2: Yes it is. Very bad idea. :td: Akin to doing surgery on yerself with a table knife and scotch tape. Ye might survive.

probably

Love that word. Comes directly out the sermons of the "it ain't blowed up yet" crowd.

- Joined

- Dec 25, 2011

- Messages

- 9,345

- Reaction score

- 4,522

I've been trying to figure out the motivation for such a bad drum and breech plug design when the problem could have been so easily mitigated by moving the barrel back so the drum could be placed ahead of the breech plug through the barrel wall.

If one wants to go this route than why not go with the patten breech idea and dispense with the separate drum altogether. Mike D.

If one wants to go this route than why not go with the patten breech idea and dispense with the separate drum altogether. Mike D.

- Joined

- Nov 10, 2005

- Messages

- 439

- Reaction score

- 46

M.D. said:I've been trying to figure out the motivation for such a bad drum and breech plug design when the problem could have been so easily mitigated by moving the barrel back so the drum could be placed ahead of the breech plug through the barrel wall.

If one wants to go this route than why not go with the patten breech idea and dispense with the separate drum altogether. Mike D.

I wouldn't call it bad, only different. The drum/bolster is a much stronger arrangement than the conventional drum you describe. As to a patent breech, that's just another different system also, and also with a narrowed channel from the base of the bore.