Hi,

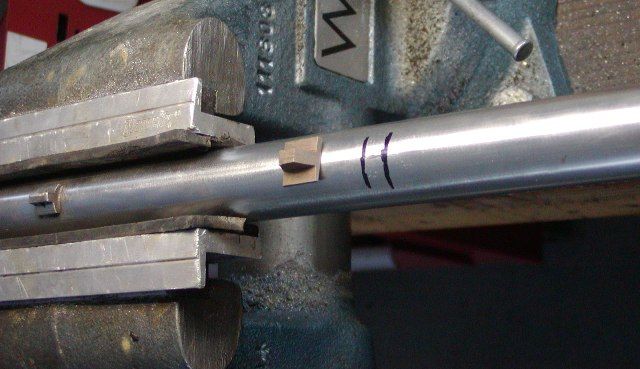

Before moving on to metal work, I wanted take care of the missing butt plate tang pin. Original Besses have a lug cast into the underside of the butt plate tang through which a pin is inserted. The location is always where the final shoulder is on the tang. On real Besses, the pin secured the top of the butt plate. On the Pedersoli, it cannot serve that purpose because there is no lug, however, the pin shows on originals so why not just add a pin to the Pedersoli. I simply drill a 1/16” hole through the butt and tap in a 1/16” pin trimmed to the width of the stock minus a little so the ends are sunken in the wood a tiny bit.

Oh boy, now to clean up the barrel. I think I’ll let my minion, Kenny, do this job.

After cleaning the bore with oil, patches, and steel wool to get out pitting, I began taking off the browning. I scrubbed the barrel with comet and a green Scotch-Brite pad, which cleans up the gunk and rubs away much of the brown. Then I use a 60 grit (yellow) 3-M bristle burr mounted on my Dremel to clean off the rest of the brown and polish the barrel. I wear a face mask when I do this because the burr kicks up a lot of very fine powder containing the browning. The little bristle burrs do a great job and work fast. I then rub the barrel with medium and fine Scotch-Brite pads dipped in water to polish the barrel a bit more. I’ll leave it at that for now.

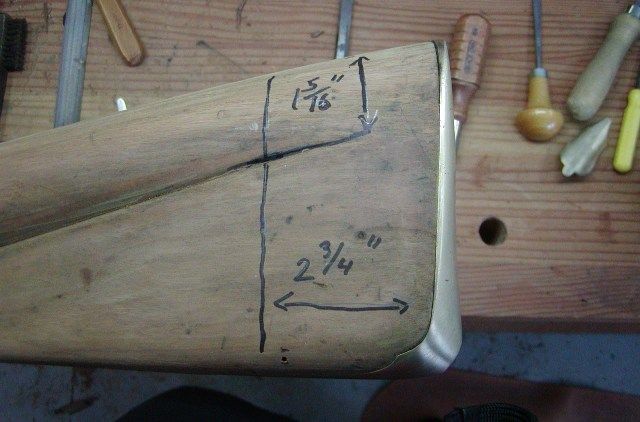

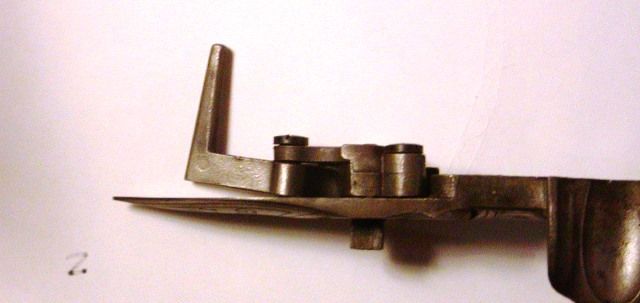

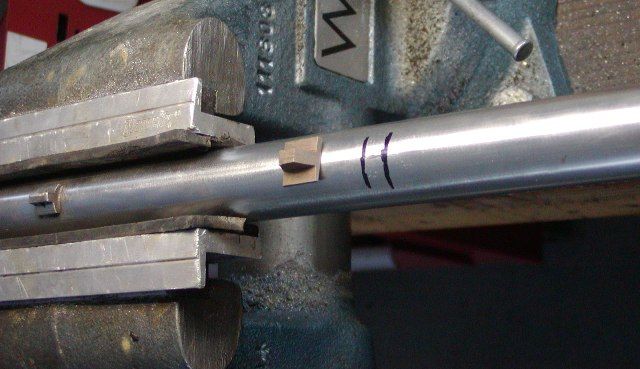

Original Besses have a lug brazed on the barrel through which the screw for the foreward slig swivel passes. This provides support for the swivel so that it is not entirely bearing on the wood. Pedersolis do not have the lug, which is a weakness. I will add a lug. I mark the location on the barrel and make a small lug with concave bottom from some mild steel scrap. It should be about 1/2”-5/8” long, about 7/16” wide, and 1/4” high. I basically make it using a hacksaw and some files. Making sure it fits nicely on the curve of the barrel, I solder it in place using Brownell’s Hi-Force 44 low temp silver bearing solder. This stuff is very strong but you have to make sure the surfaces to be soldered are very clean or the solder will not flow.

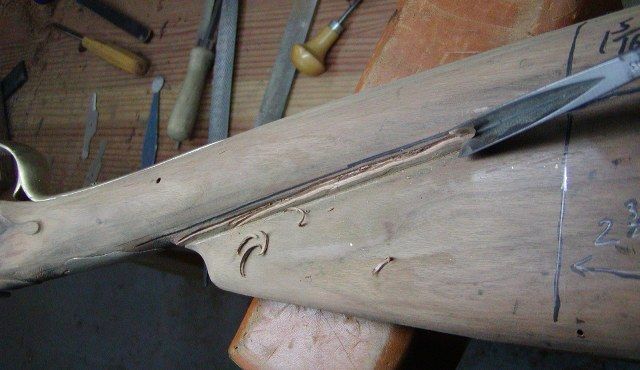

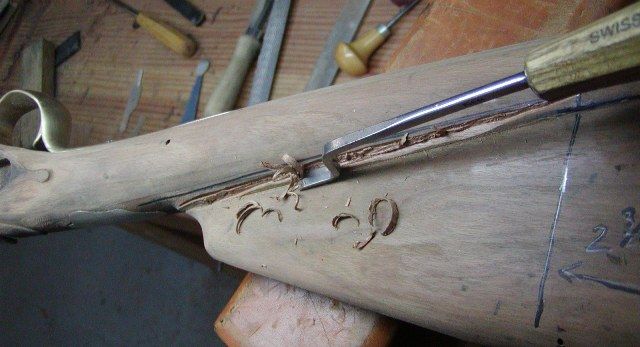

Once the lug is soldered in place, I coat the top with some inletting black and press the barrel into the barrel channel to mark the location for inletting the lug. Using 1/4” and 1/8” flat chsiels and a small #3 sweep gouge, I inlet the lug and its base. It is easy to do and don’t worry if it breaks into the ramrod channel because it is about 1/4” high, which is about the thickness of the web of wood between the barrel and ramrod. After inletting the lug, put the barrel in the stock and put the barrel pins in and tang bolt screwed into the trigger plate to set the barrel tightly in place. Then using a drill about half the diameter of the swivel screw, drill in the swivel hole from one side into the lug but don’t go completely through the lug. Then drill from the other side until through the lug. The holes should meet pretty closely. Then use a drill the diameter of the screw or a tiny bit larger, and repeat the drilling from both sides. If you are careful, it will all line up just fine. After mounting the swivel on the gun, I check to make sure it overlaps the ramrod thimble behind it. It must do that, or the swivel will block the ramrod going back down the channel during loading. Original swivels were welded rod. This one is cast and the loop is too neatly compressed such that it barely overlaps the thimble. I heat it and bend it to open it up so the overlap increases. In doing that, the swivel loop also looks a lot more authentic.

dave