Hi Folks,

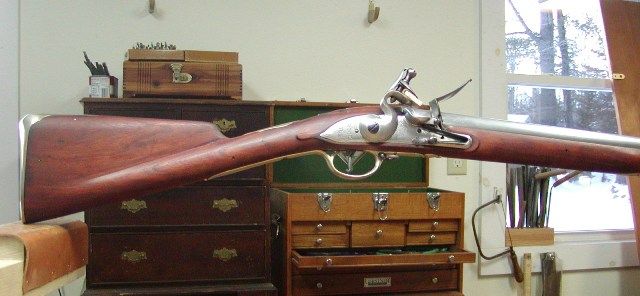

OK, a big post about the lock work. This will be a doozy. This particular Pedersoli Bess lock saw a lot of use and was abused. First, some history. The lock on the Pedersoli Besses are the style used on pattern 1756 and 1769 Besses with the wrong markings. It shows only one screw hole behind the flintcock because it has a long sear spring. Later Bess locks showed 2 screws because they shortened the sear spring and they added a hole to the top jaw screw. The Pedersoli Bess lock does not represent a late Rev War or Napoleonic War Bess lock.

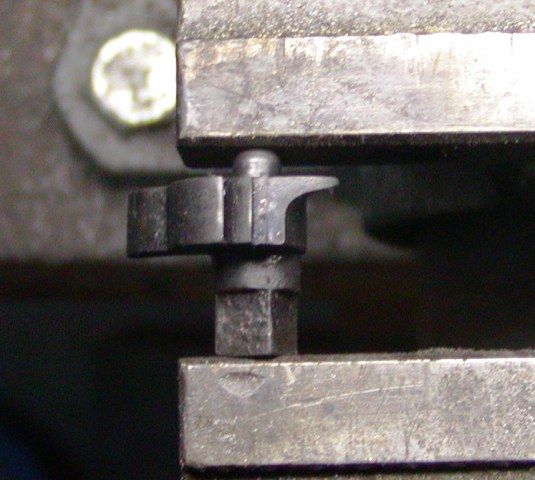

The frizzen was very worn, the plate and flintcock were very rust pitted, and the internal parts needed a lot of work. First, I had to clean it up. I washed it in hot soapy water and then sprayed it with Ballistol to disperse the water and clean off the gunk. I previously showed the problem with the sear screw hole. I annealed all the internal parts by heating them to bright orange with a MAPP torch and letting them cool slowly. To fix the sear, I annealed it and then filed the screw hole true using a rat tailed needle file. Once the hole was corrected, I cleaned it up by using a proper sized drill and my drill press to ream the hole. I then filed a slightly larger screw to fit the hole in the sear and threaded it to fit the lockplate. That solved the problem. Next, I straightened the lower leaf of the sear spring so it contacted the sear closer to the sear screw. I’ll discuss hardening and tempering springs later. Note the contact between the sear spring and the sear in the photo below.

I also heated and modified the mainspring so that the lower leaf was almost straight at full cock instead of having a bend upward in the middle of the leaf. I added preload to it and I also opened up the hook so it engaged the tumbler a little deeper at rest. I harden springs by heating them bright orangy red and quenching in canola oil. Then I clean them up and temper them in my oven at 750 degrees F for 1 hour. That creates perfect springs.

The cock on Pedersoli Bess locks have much too long a throw because the full cock notch on the tumbler is too far from the halfcock notch. I annealed the tumbler and then cut a new full cock notch about 1/16” in front of the existing notch. The old line of the fullcock notch is clear in the photo below.

When changing the notch, the face of the full cock notch must be in a direct line with a radius drawn from the center of the tumbler pivot. After cutting the notch, I stoned it to match that geometry. The flintcock now has a shorter throw but a distance that makes the lock faster, less likely to fall into the halfcock notch during firing, and less damaging of flints. It is a better lock.

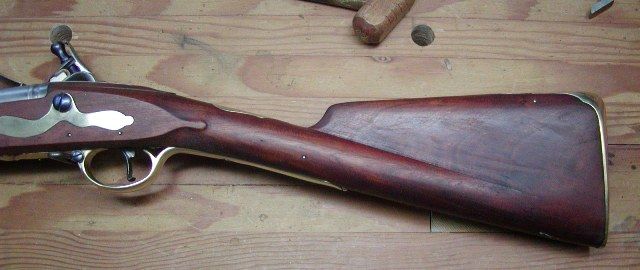

The next job was the frizzen. I polished the surface of the frizzen to remove most of the gouges and then modified the toe so it snaps open faster. The photo below shows the angle of the frizzen above the pan at the point at which it will snap open from the spring pressure. It is about 30 degrees above the pan. I adjust that point by grinding the toe of the frizzen at the angle shown by the red line in the photo. I also make sure the upper leaf of the frizzen spring is highly polished so there is little friction owing to a rough surface.

By grinding off the front edge of the toe at an angle, you create a cam in which the spring knocks the frizzen forward when pushed beyond that point. Keep in mind, that a good flintlock should produce great sparks even if there is no spring on the frizzen. The frizzen spring is really meant to provide a little resistance to the flint but more to keep the pan cover closed over the priming even if knocked about. I polish the inside of the pan so it is easier to clean and resist rust.

I cleaned up all the lock parts using 3-M bristle burrs mounted on my Dremel but then stoned them using stones lubricated with mineral oil to smooth and polish the surfaces. Then I rubbed the surfaces with a steel burnisher to create the authentic shine and polish.

I polished the screws and cut the screw slots wider, and then hardened, and tempered all the screw heads so they resist rust and wear. I heat them with a MAPP torch to bright orange, dip them in KaseNit, heat them back to orange, and then quench in water. After hardening, I clean off the residue with 3M bristle burrs and then heat them with a butane mini-torch until they turn indigo blue. That tempers them. I dip them hot into Vaseline containing carbolic acid and let them smoke. That creates a very rust resistant surface on the metal. I get the Vaseline from Ron’s Apothecary in Juneau, Alaska. It is the same as “medicated Vaseline” that used to be widely sold. The original screws were not hardened but today’s reenactors may want to protect their investments as best they can.

Finally, I pack all of the sear, bridle, frizzen, and tumbler into a box containing bone and wood charcoal, and then heat them in my oven to 1575 degrees for 1 hour. The pack is quenched in water and then the frizzen is tempered at 400 degrees for 1 hour and the other parts 575 degrees for 1 hour. They are let cool slowly. I heat treat the sear, tumbler, and bridle together so they achieve equal hardness. That way no part wears on the other. I polish all the internal parts with stones and mineral oil. After assembling the lock, it is done.

Thanks for looking,

dave