You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rust Bluing

- Thread starter Siringo

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

plmeek

40 Cal.

There are some semantics that need to be clarified to address your question.

Rust bluing usually refers to the process of placing a piece of metal that has been rust browned into boiling water which causes a change in the iron that in turn causes it to turn from brown to a blue/black color. So rust bluing probably followed closely behind rust browning which became more common near the end of the 18th century in America.

There are other blueing techniques that are probably older.

One is temper bluing aka heat bluing aka fire bluing. This is the process of heating a piece of iron or steel in a controlled manner until it reaches the desired temperature and color. A temper blue finish is not very durable.

The other is charcoal bluing. This process places the metal part in a bed of coals and allowing it to heat up until it attains the desired color. The benefit of this process is that a thin layer of forge scale usually forms that provides a layer of protection to the finish and makes it more durable. The drawback it that the finish can be mottled or blotchy.

Temper bluing and charcoal bluing evidently date back a long ways as they easily could have been observed and perfected in a blacksmith forge.

Rust bluing usually refers to the process of placing a piece of metal that has been rust browned into boiling water which causes a change in the iron that in turn causes it to turn from brown to a blue/black color. So rust bluing probably followed closely behind rust browning which became more common near the end of the 18th century in America.

There are other blueing techniques that are probably older.

One is temper bluing aka heat bluing aka fire bluing. This is the process of heating a piece of iron or steel in a controlled manner until it reaches the desired temperature and color. A temper blue finish is not very durable.

The other is charcoal bluing. This process places the metal part in a bed of coals and allowing it to heat up until it attains the desired color. The benefit of this process is that a thin layer of forge scale usually forms that provides a layer of protection to the finish and makes it more durable. The drawback it that the finish can be mottled or blotchy.

Temper bluing and charcoal bluing evidently date back a long ways as they easily could have been observed and perfected in a blacksmith forge.

- Joined

- Nov 26, 2005

- Messages

- 5,229

- Reaction score

- 10,903

Hi Phil,

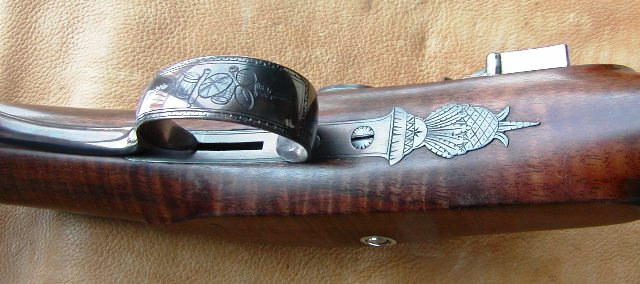

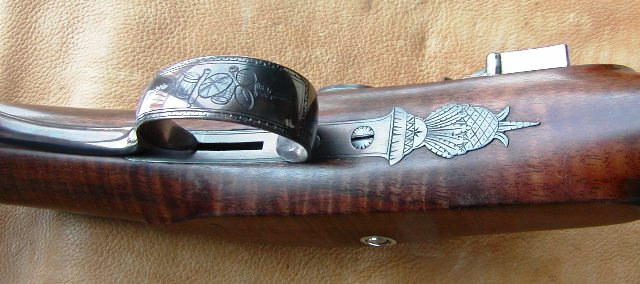

Charcoal bluing is only blotchy when done by folks who cannot control the process very well. Here is charcoal bluing done correctly as the British did it during the late 18th and early 19th centuries:

dave

Charcoal bluing is only blotchy when done by folks who cannot control the process very well. Here is charcoal bluing done correctly as the British did it during the late 18th and early 19th centuries:

dave

plmeek

40 Cal.

Charcoal bluing is only blotchy when done by folks who cannot control the process very well.

Ok, Dave, I'll bite. What's the secret to controlling the process?

- Joined

- Nov 26, 2005

- Messages

- 5,229

- Reaction score

- 10,903

Hi Phil,

The most important part is the surface of the metal has to be highly and evenly polished and then thoroughly degreased. Parts and barrel are packed in charcoal and heated. The heat needs to be kept within 800-900 degree range and held there for 2-3 hours. Then the barrel or parts are removed, cooled just sufficient to handle, and rubbed with linseed oil and rottenstone, degreased again, packed in charcoal, and heated again. The cycle is repeated until the barrel and components are evenly colored. It is a very labor intensive process but yields a deep metallic blue with an almost mirror finish. The blotchiness seen on some barrels is because the finisher did not evenly polish or thoroughly degrease the barrel and/or did not perform enough cycles to get even color.

dave

The most important part is the surface of the metal has to be highly and evenly polished and then thoroughly degreased. Parts and barrel are packed in charcoal and heated. The heat needs to be kept within 800-900 degree range and held there for 2-3 hours. Then the barrel or parts are removed, cooled just sufficient to handle, and rubbed with linseed oil and rottenstone, degreased again, packed in charcoal, and heated again. The cycle is repeated until the barrel and components are evenly colored. It is a very labor intensive process but yields a deep metallic blue with an almost mirror finish. The blotchiness seen on some barrels is because the finisher did not evenly polish or thoroughly degrease the barrel and/or did not perform enough cycles to get even color.

dave

Siringo

32 Cal.

- Joined

- Nov 25, 2014

- Messages

- 324

- Reaction score

- 264

Mike Lee (?) offers a Rust Blue product. Heat barrel to 200 degrees and apply solution. Card and then immerse in boiling water. Repeat. I guess it is supposed to be more blue than using browning solution and immerse. That turning more black.There are some semantics that need to be clarified to address your question.

Rust bluing usually refers to the process of placing a piece of metal that has been rust browned into boiling water which causes a change in the iron that in turn causes it to turn from brown to a blue/black color. So rust bluing probably followed closely behind rust browning which became more common near the end of the 18th century in America.

There are other blueing techniques that are probably older.

One is temper bluing aka heat bluing aka fire bluing. This is the process of heating a piece of iron or steel in a controlled manner until it reaches the desired temperature and color. A temper blue finish is not very durable.

The other is charcoal bluing. This process places the metal part in a bed of coals and allowing it to heat up until it attains the desired color. The benefit of this process is that a thin layer of forge scale usually forms that provides a layer of protection to the finish and makes it more durable. The drawback it that the finish can be mottled or blotchy.

Temper bluing and charcoal bluing evidently date back a long ways as they easily could have been observed and perfected in a blacksmith forge.

- Joined

- Nov 26, 2005

- Messages

- 5,229

- Reaction score

- 10,903

Hi,

You can rust blue a barrel by browning it and then immersing it in boiling water. It will turn blue-black. Both rust browning and rust bluing are very durable. Generally the slower the process the more durable the finish.

dave

You can rust blue a barrel by browning it and then immersing it in boiling water. It will turn blue-black. Both rust browning and rust bluing are very durable. Generally the slower the process the more durable the finish.

dave

Phil Coffins

69 Cal.

This pistol was charcoal blued by polishing then cleaning before packing in wood charcoal. I held it at 800f for three hours and let it cool over night in the pack. Then oiled with light machine oil. With out the extra steps that Dave described you can see the blotchy color. I was young (60) and didn’t know any better.

IMG_0400 by Oliver Sudden, on Flickr

IMG_0400 by Oliver Sudden, on Flickr

IMG_0400 by Oliver Sudden, on Flickr

IMG_0400 by Oliver Sudden, on Flickrplmeek

40 Cal.

Thank you Dave.

I do recall David Rase posting a thread on another forum where he was charcoal bluing barrels in a charcoal pack. He was using steel pipe to hold the charcoal and barrel and surrounded this with heat tape, insulation and an aluminum tube around the outside. Here is a photo of his setup.

I wasn't sure how similar this approach was to how it might have been done in the 18th century. Obviously, they didn't have heat tape back then and I don't know if they had steel pipe of the appropriate length and diameter to hold the barrel and charcoal.

I can see that polishing the surface of the metal would be key to getting a really nice uniform finish. The process you describe sounds time consuming and therefore expensive. Something I would expect on a high quality European or English gun.

It does remind me of a reference I saw in the Henry Papers at the Hagley that J. Joseph Henry was charging more for blued barrels on his rifles than for brown or bright barrels. I'll have to check my notes for the specific reference. But anyway, it made me think that they were likely temper bluing or charcoal bluing rather than rust bluing because I didn't see how the latter would be much more expensive to do than just browning.

This is a page from the Shop Blotter that William Henry III kept in 1819-22, 1824 (part of the records at the Jacobsburg Historical Society). At the bottom, he has drawn a sketch of a barrel oven and included the dimensions. I can't quite make out the word where he writes , "Oven for ???? Barrels". It looks like it could be creative spelling for "annealing". But I'm not sure why they need to anneal wrought iron barrels. I wondered if the word was used to mean heating the barrels to temper blue them. Of course, if they had a container to pack the barrels in charcoal, they could have been charcoal bluing the barrels in a similar fashion to the process you described. Do you have any thoughts on what the oven might have been used for?

I've shown the document below before in another thread. It is part of a letter from Ramsey Crooks to J. J. Henry dated February 17, 1829 in which Crooks is expressing his disatifaction with Henry's bluing on some Northwest trade gun barrels.

It kind of sounds like Henry wasn't polishing the barrels on his NW guns as much as the English were and therefore not getting them a "bright lively blue" like on the English guns.

I do recall David Rase posting a thread on another forum where he was charcoal bluing barrels in a charcoal pack. He was using steel pipe to hold the charcoal and barrel and surrounded this with heat tape, insulation and an aluminum tube around the outside. Here is a photo of his setup.

I wasn't sure how similar this approach was to how it might have been done in the 18th century. Obviously, they didn't have heat tape back then and I don't know if they had steel pipe of the appropriate length and diameter to hold the barrel and charcoal.

I can see that polishing the surface of the metal would be key to getting a really nice uniform finish. The process you describe sounds time consuming and therefore expensive. Something I would expect on a high quality European or English gun.

It does remind me of a reference I saw in the Henry Papers at the Hagley that J. Joseph Henry was charging more for blued barrels on his rifles than for brown or bright barrels. I'll have to check my notes for the specific reference. But anyway, it made me think that they were likely temper bluing or charcoal bluing rather than rust bluing because I didn't see how the latter would be much more expensive to do than just browning.

This is a page from the Shop Blotter that William Henry III kept in 1819-22, 1824 (part of the records at the Jacobsburg Historical Society). At the bottom, he has drawn a sketch of a barrel oven and included the dimensions. I can't quite make out the word where he writes , "Oven for ???? Barrels". It looks like it could be creative spelling for "annealing". But I'm not sure why they need to anneal wrought iron barrels. I wondered if the word was used to mean heating the barrels to temper blue them. Of course, if they had a container to pack the barrels in charcoal, they could have been charcoal bluing the barrels in a similar fashion to the process you described. Do you have any thoughts on what the oven might have been used for?

I've shown the document below before in another thread. It is part of a letter from Ramsey Crooks to J. J. Henry dated February 17, 1829 in which Crooks is expressing his disatifaction with Henry's bluing on some Northwest trade gun barrels.

Crooks writes, "I do not think them of that bright lively blue which distinguishes the English and on which I trust you will bestow your most particular attention until your Guns are really of as fine a color as those we have been in the habit of importing when I shall readily pronounce them every way equal."

It kind of sounds like Henry wasn't polishing the barrels on his NW guns as much as the English were and therefore not getting them a "bright lively blue" like on the English guns.

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 3

- Views

- 197

- Replies

- 6

- Views

- 362