-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smacking the lock

- Thread starter Sharpie44

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

R.M. said:OK, can somebody answer me this? We hear about picking the vent to create a hollow. Then we hear about coning the vent to get the charge closer to the pan.

Aren't the 2 opposite each other?

No. Picking the vent opens the path from the priming to the main charge. Coning the inside of the vent brings the main charge closer to the priming and shortens the path between the two.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

No. Picking the vent does create a hole in the powder charge, but it does not remove powder from the inside cone, save in the very center. There is still powder on the bottom of the cone, and occasionally, stuck to the top and sides of the cone, too.

Trust me, If using a vent pick to move powder around and create a hole would remove all the powder from the inside-coned vent liners, ignition would be slowed, and I would not be recommending the procedure. I learned about picking a hole( Or leaving a vent pick in the barrel during loading of the powder and PRB) from a friend of mine who had grown up with flintlocks, and knew more about tuning them than any other man I had ever met. The few flintlock shooters in our club were " USED TO " the slow, fuse effect delayed firing of their guns. They thought that was just how a flintlock is fired- ala Davy Crockett TV Show. When he came to the club, and his gun was firing off almost instantly, EVERYONE STOPPED. Everyone wanted to know how he did that. The 2 flinters walked down the line to listen, and watch, and then try it with their own guns under his supervision and direction. I remember the first guy to shoot his gun after picking the main charge physically jumped back when his gun went off so fast. He laughed at his silliness, with the rest of us, and then said, " Let's try that again!" The other shooter fired and had a 10X. The percussion shooters all hollered, " HEY, Stop that!" All he could do was turn around and give them a huge Cheshire Grin. Within 2-3 years almost every percussion rifle shooter in the club owned and shot a Flintlock- all because Don was there to teach them how to load and shoot flintlocks, to make repairs, and "tune" the locks on their guns.

Trust me, If using a vent pick to move powder around and create a hole would remove all the powder from the inside-coned vent liners, ignition would be slowed, and I would not be recommending the procedure. I learned about picking a hole( Or leaving a vent pick in the barrel during loading of the powder and PRB) from a friend of mine who had grown up with flintlocks, and knew more about tuning them than any other man I had ever met. The few flintlock shooters in our club were " USED TO " the slow, fuse effect delayed firing of their guns. They thought that was just how a flintlock is fired- ala Davy Crockett TV Show. When he came to the club, and his gun was firing off almost instantly, EVERYONE STOPPED. Everyone wanted to know how he did that. The 2 flinters walked down the line to listen, and watch, and then try it with their own guns under his supervision and direction. I remember the first guy to shoot his gun after picking the main charge physically jumped back when his gun went off so fast. He laughed at his silliness, with the rest of us, and then said, " Let's try that again!" The other shooter fired and had a 10X. The percussion shooters all hollered, " HEY, Stop that!" All he could do was turn around and give them a huge Cheshire Grin. Within 2-3 years almost every percussion rifle shooter in the club owned and shot a Flintlock- all because Don was there to teach them how to load and shoot flintlocks, to make repairs, and "tune" the locks on their guns.

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

Hi Paul,

I wrote this early this morning in response to your earlier post and then sat on it thinking about how to run the test mentioned at the end:

Separating heat from fire in a flintlock world is futile. I can ignite a pan with a red hot wire and avoid using a flame. But I can’t introduce a flame without heat. It may be possible to hold a match above a pile of prime close enough to ignite from the match’s heat with out touching the prime with the flame, but in a flintlock world that serves no purpose.

What we want to do is introduce a massive, intense amount of heat as quickly as possible through to vent hole. In flintlocks, that is done with the flame front produced when the pan ignites. The speed of the flame front traveling from the ignition point has not been measured when dealing with flintlocks. It is studied carefully in the field of internal combustion engines. The flame front in engines travels insanely fast. (My son’s Yamaha 600 crotch rocket redlined at 15,000 rpm. A spark ignites a gas mix 125 times a second.)

Where we’re at in this discussion is to ask is, “Which affects barrel ignition the most ”“ convection speed (heat rising) or flame front speed? Since I have not measured this I will only speculate; but IMHO the speed of the flame front trumps convection every time.

Paul, I agree that heat ignites the barrel charge, but I also believe that the flame front is the carrier. I deliver heat by delivering flame. If the high, level, and low vent positions were affected by convection, then the high vent position should have been noticeably faster. It wasn’t; times from all locations were largely the same.

I believe that this question can be studied by additional photography. I can’t photograph heat, but I can photograph the flame that delivers it. All the previous photography was done with the vent in the level position. I think I’ll set up to do the same shot but use low, level, and high vent positions. If heat rising (convection) is the dominating factor, we should see the high vent have the advantage, noted by the amount of flame in the shot. If flame front is the dominating factor, the resulting flame should be unaffected by vent location.

Regards,

Pletch

I wrote this early this morning in response to your earlier post and then sat on it thinking about how to run the test mentioned at the end:

Separating heat from fire in a flintlock world is futile. I can ignite a pan with a red hot wire and avoid using a flame. But I can’t introduce a flame without heat. It may be possible to hold a match above a pile of prime close enough to ignite from the match’s heat with out touching the prime with the flame, but in a flintlock world that serves no purpose.

What we want to do is introduce a massive, intense amount of heat as quickly as possible through to vent hole. In flintlocks, that is done with the flame front produced when the pan ignites. The speed of the flame front traveling from the ignition point has not been measured when dealing with flintlocks. It is studied carefully in the field of internal combustion engines. The flame front in engines travels insanely fast. (My son’s Yamaha 600 crotch rocket redlined at 15,000 rpm. A spark ignites a gas mix 125 times a second.)

Where we’re at in this discussion is to ask is, “Which affects barrel ignition the most ”“ convection speed (heat rising) or flame front speed? Since I have not measured this I will only speculate; but IMHO the speed of the flame front trumps convection every time.

Paul, I agree that heat ignites the barrel charge, but I also believe that the flame front is the carrier. I deliver heat by delivering flame. If the high, level, and low vent positions were affected by convection, then the high vent position should have been noticeably faster. It wasn’t; times from all locations were largely the same.

I believe that this question can be studied by additional photography. I can’t photograph heat, but I can photograph the flame that delivers it. All the previous photography was done with the vent in the level position. I think I’ll set up to do the same shot but use low, level, and high vent positions. If heat rising (convection) is the dominating factor, we should see the high vent have the advantage, noted by the amount of flame in the shot. If flame front is the dominating factor, the resulting flame should be unaffected by vent location.

Regards,

Pletch

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

Yeah, we still agree, Larry. I did my learning watching a candle flame, noting the cone of air inside the flame, around the wick, and upwards from there. The HOttest part of the flame is always at the top, and even slightly above the highest visible flame. When we were in Junior High science, we kids spent hours trying to put a stick match head quickly through the side of a candle flame, to get it in the middle of that air "bubble" inside the flame. Of course, the match stick burned eventually ( a few seconds) while sitting in the side of the flame, but it was fun to see the fire work inward to the matchhead to ignite it INSIDE the flame.

A Misspent Youth, to be sure. :shocked2: :rotf:

Phil Quaglino has been building guns for many years, and it was he who told brother Peter that the optimum location, IHHO, was .030" above the top of the pan. He wanted to maximize the amount of powder in the pan to produce the biggest FLAME. He also always picked hit vent hole with his vent pick, to create a hole in the main charge to speed barrel ignition.

My Gunmaker, Craig Witte, is the man who widened the frizzen, and then polished it to a mirror finish to give as wide a target for the sparks to hit coming down off the frizzen. The mirror polish not only made it much easier to clean the pan between shots, but it apparently reflects HEAT from the flame upward, and toward the barrel, too( The curve around the outside edge of the pan). I have the high TH on my fowler that Craig built, and I have tried ignition with my usual 1/2 pan full of priming powder( 4Fg), and then again with a full pan of priming powder. The gun seems to go off a little bit faster with the full pan. There is no doubt about the amount of flame a full pan produces, that is for sure!

Craig has shot the Primitive matches at Friendship for many years, and has his own flintlock rifle and smoothbore set up the same way he made my lock and TH. He says he has never experienced a misfire, or hangfire with his guns on the line doing this. He is a second generation gunsmith and gun builder, and he was taught very well by his father.( O.E. "Curly" Witte, now of Salmon River, British Columbia).

When two different gun makes, with years of both personal and practical knowledge and advice from their own mentors indicate that the Th should optimally be located above the pan, and they live in different parts of the country, and have never met, I think the information is worth considering. I have been converted: I want a big flame now, too. :hatsoff:

A Misspent Youth, to be sure. :shocked2: :rotf:

Phil Quaglino has been building guns for many years, and it was he who told brother Peter that the optimum location, IHHO, was .030" above the top of the pan. He wanted to maximize the amount of powder in the pan to produce the biggest FLAME. He also always picked hit vent hole with his vent pick, to create a hole in the main charge to speed barrel ignition.

My Gunmaker, Craig Witte, is the man who widened the frizzen, and then polished it to a mirror finish to give as wide a target for the sparks to hit coming down off the frizzen. The mirror polish not only made it much easier to clean the pan between shots, but it apparently reflects HEAT from the flame upward, and toward the barrel, too( The curve around the outside edge of the pan). I have the high TH on my fowler that Craig built, and I have tried ignition with my usual 1/2 pan full of priming powder( 4Fg), and then again with a full pan of priming powder. The gun seems to go off a little bit faster with the full pan. There is no doubt about the amount of flame a full pan produces, that is for sure!

Craig has shot the Primitive matches at Friendship for many years, and has his own flintlock rifle and smoothbore set up the same way he made my lock and TH. He says he has never experienced a misfire, or hangfire with his guns on the line doing this. He is a second generation gunsmith and gun builder, and he was taught very well by his father.( O.E. "Curly" Witte, now of Salmon River, British Columbia).

When two different gun makes, with years of both personal and practical knowledge and advice from their own mentors indicate that the Th should optimally be located above the pan, and they live in different parts of the country, and have never met, I think the information is worth considering. I have been converted: I want a big flame now, too. :hatsoff:

I used to turn the lock side down and tap the sideplate to move the prime away from the vent hole. I don't do that anymore after doing some squirrel hunting where the prime gets tossed around the pan before I take my shots. The rifle always went off great no matter where the primer was sitting.

I still always tap my barrel 8 times after I pour my main charge down the barrel to settle the powder.

I still always tap my barrel 8 times after I pour my main charge down the barrel to settle the powder.

Joel/Calgary

50 Cal.

- Joined

- Oct 19, 2004

- Messages

- 1,251

- Reaction score

- 6

I read somewhere mention of a test of whether radiant heat alone could ignite the main charge, by using a thin muscovite mica "window" between the pan and the touchhole. It fired. This test would not establish that this was the primary mode of ignition in the real world, just that it was possible to ignite the main charge purely by the radiant heat of the priming, in the absence of direct contact with flame or sparks. I have no idea of the rate of heating of a portion of a powder grain by the radiant heat vs. contact with the hot gasses or hot particles.

I think this was mentioned by a poster in another of these discussions on flintlock ignition dynamics, possibly on this board, but I can find no reference to either that discussion or the original tests referred to. Maybe someone with better search skills can locate it.

Regards,

Joel

I think this was mentioned by a poster in another of these discussions on flintlock ignition dynamics, possibly on this board, but I can find no reference to either that discussion or the original tests referred to. Maybe someone with better search skills can locate it.

Regards,

Joel

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

In a previous post I mentioned a photography test:

"I believe that this question can be studied by additional photography. I can’t photograph heat, but I can photograph the flame that delivers it. All the previous photography was done with the vent in the level position. I think I’ll set up to do the same shot but use low, level, and high (.030")vent positions. If heat rising (convection) is the dominating factor, we should see the high vent have the advantage, noted by the amount of flame in the shot. If flame front is the dominating factor, the resulting flame should be unaffected by vent location."

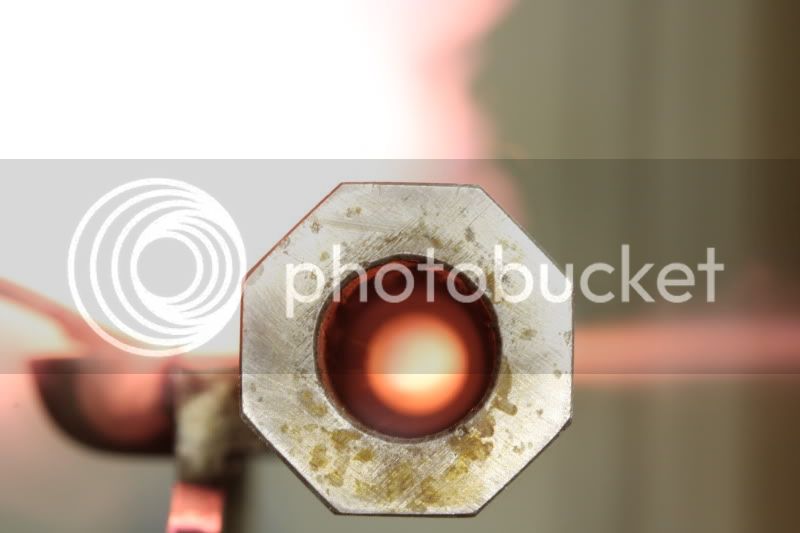

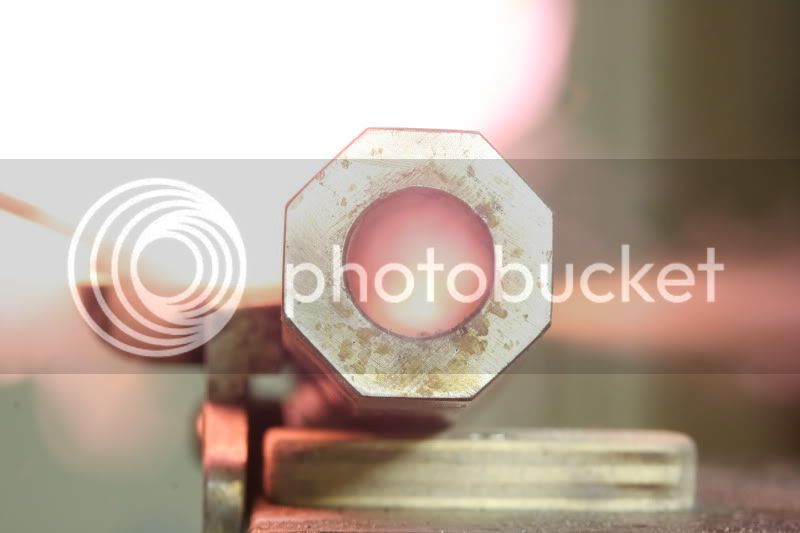

I did the photogtaphy this weekend and had a surprise. I had expected the photos from all vent locations to look the same. They were not. I used 3/4 grain Swiss null b as close to the barrel as possible. The vent positions were .030" above level, level, and bottom of the pan. I lit the prime with a red hot copper wire and took 3 photos per position. The camera was set at f13 and the shutter to 4 seconds. I heated the wire, tripped the shutter, and touched the wire to the prime. (A cable release helps, but is not necessary.)

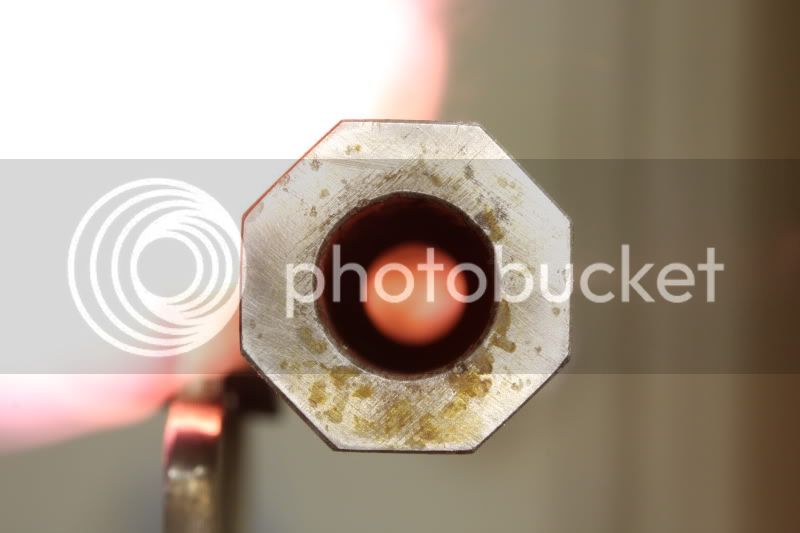

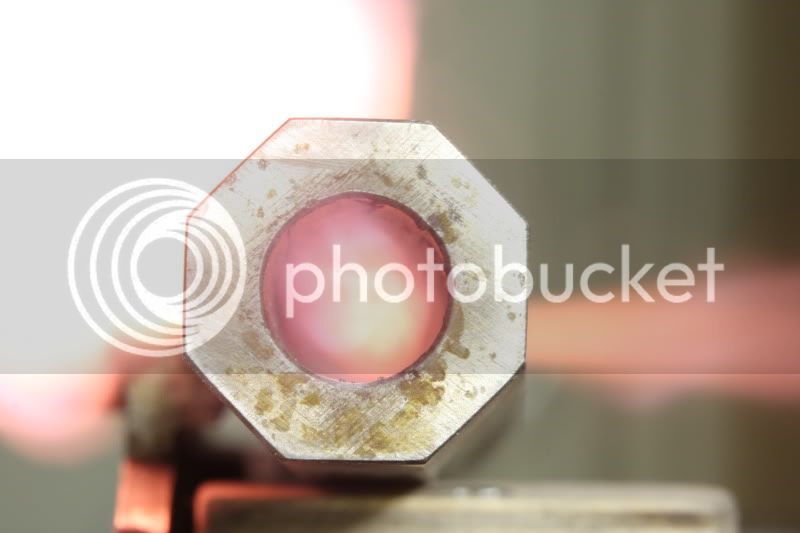

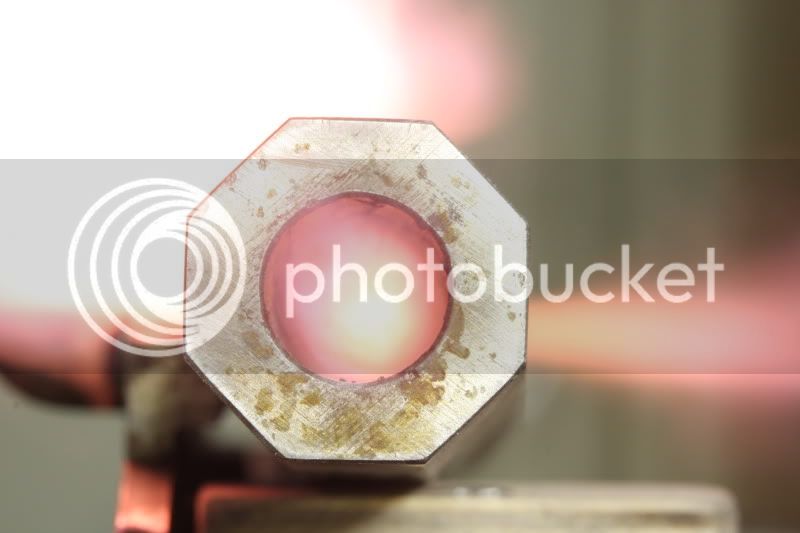

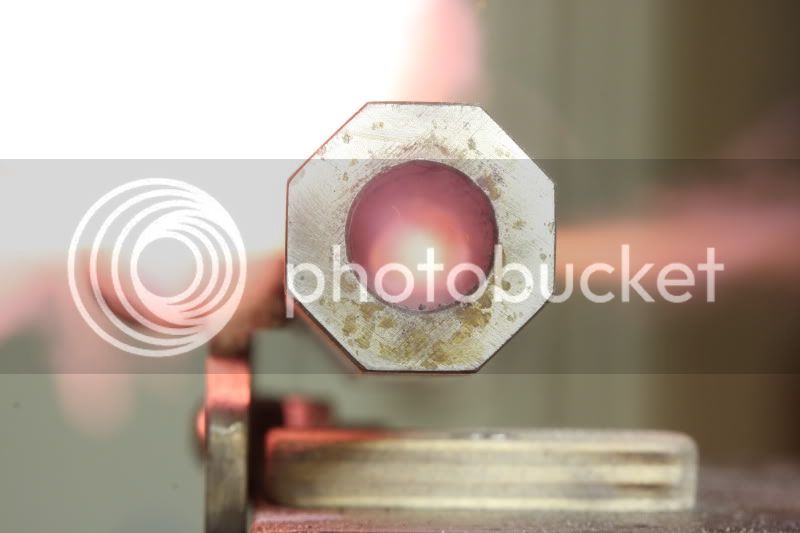

Here are the photos from the high .030" location:

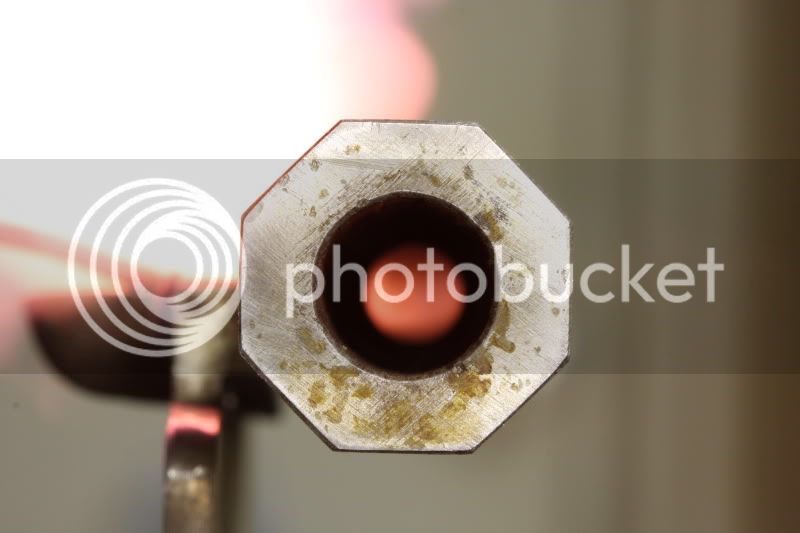

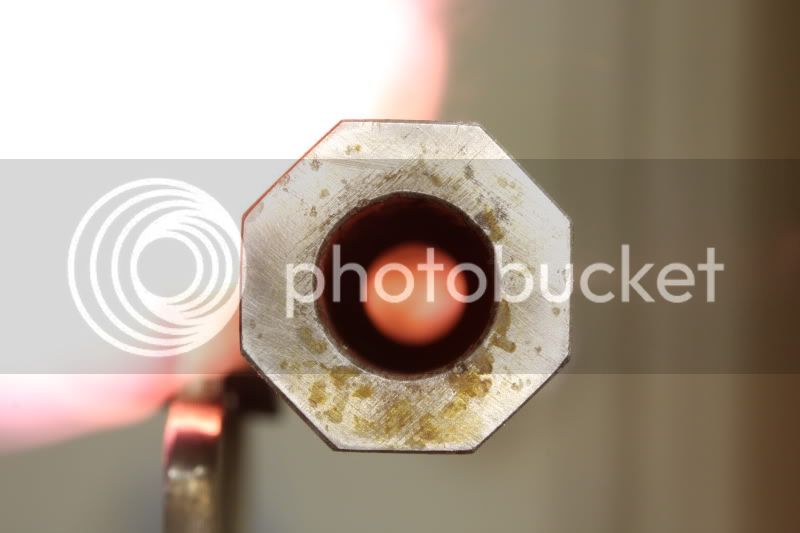

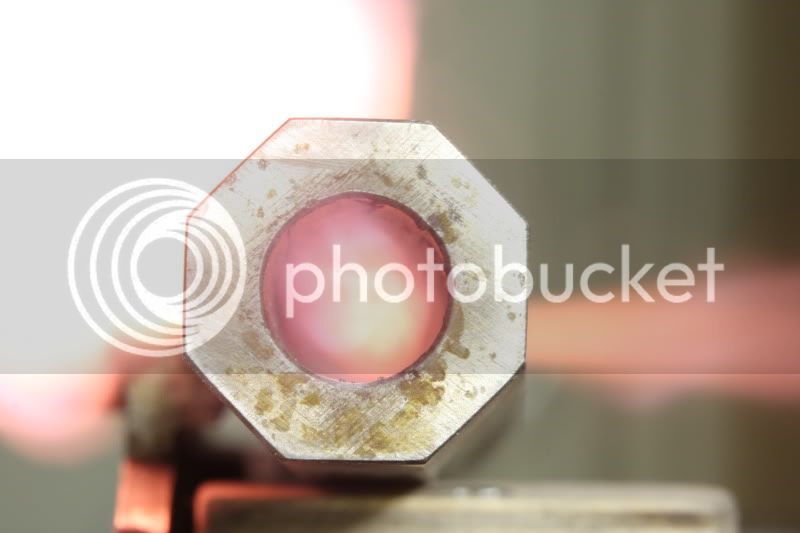

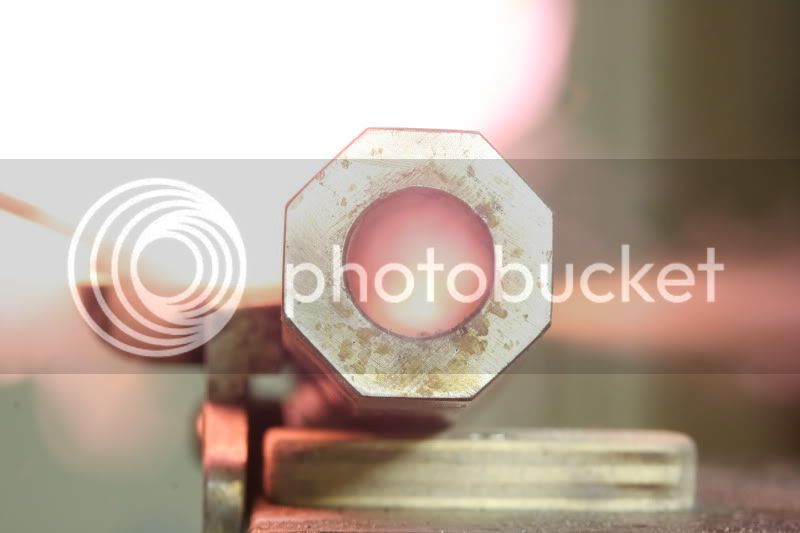

Here are the photos taken with the level pan location:

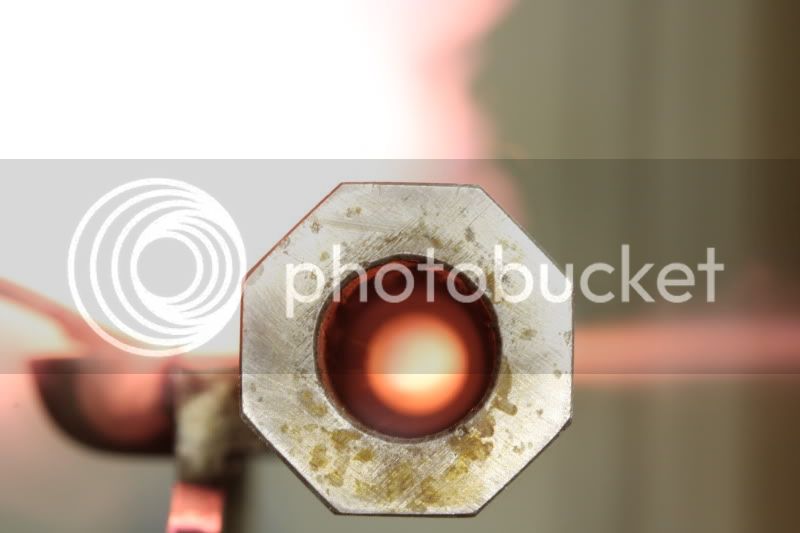

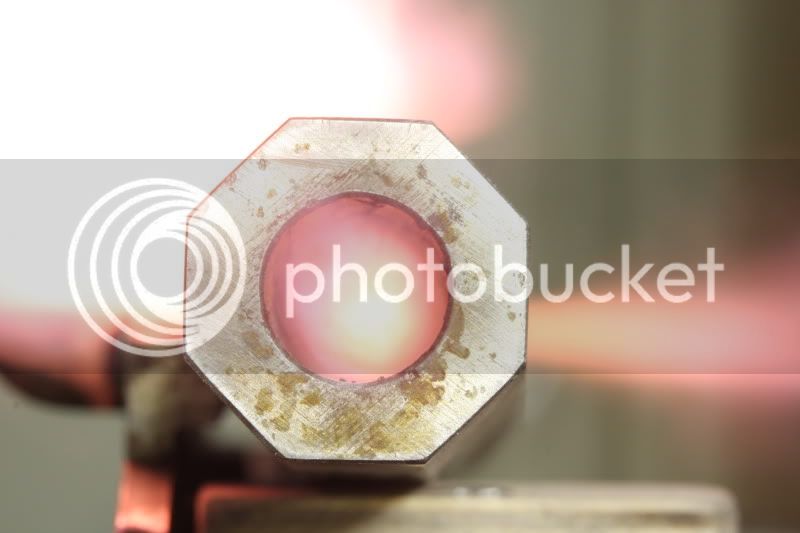

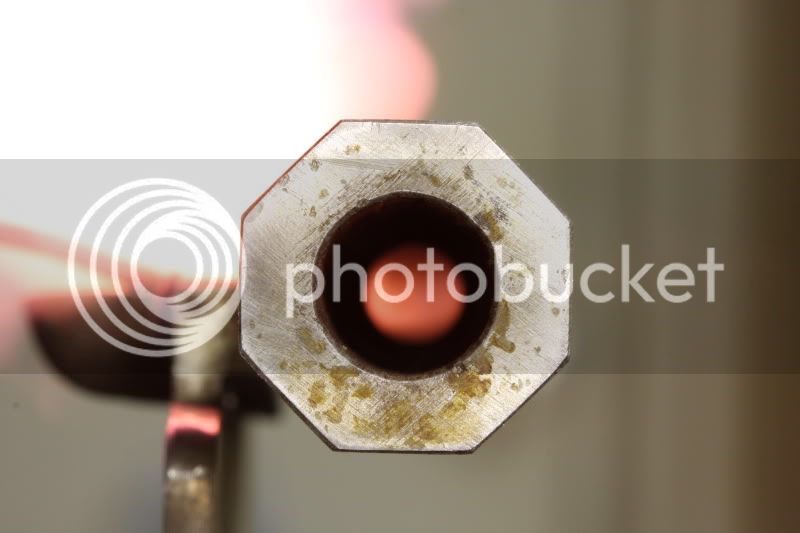

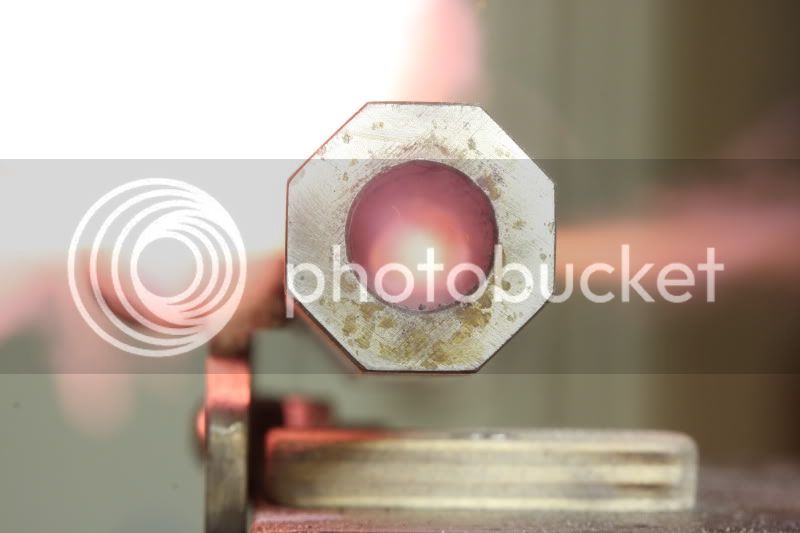

Here are the photos with the low pan location:

I was not expecting the difference between the .030" vent and the rest. I thought the .030" position would be the equal of the others.

I am beginning to think that one can have a vent too high. But it's possible that a high vent can be made to work if the shooter uses more prime. Perhaps a level or low vent can produce a good flame front through the vent with less powder, while a high vent needs a larger amount. If that would be the case, then maybe the high vent can work, it's just less efficient with powder????

Maybe it's the angle at which the flame enters the vent. Would a counter sink angled from below make a difference?

This test does make me doubt the effect of convection on flint ignition.

Regards,

Pletch

"I believe that this question can be studied by additional photography. I can’t photograph heat, but I can photograph the flame that delivers it. All the previous photography was done with the vent in the level position. I think I’ll set up to do the same shot but use low, level, and high (.030")vent positions. If heat rising (convection) is the dominating factor, we should see the high vent have the advantage, noted by the amount of flame in the shot. If flame front is the dominating factor, the resulting flame should be unaffected by vent location."

I did the photogtaphy this weekend and had a surprise. I had expected the photos from all vent locations to look the same. They were not. I used 3/4 grain Swiss null b as close to the barrel as possible. The vent positions were .030" above level, level, and bottom of the pan. I lit the prime with a red hot copper wire and took 3 photos per position. The camera was set at f13 and the shutter to 4 seconds. I heated the wire, tripped the shutter, and touched the wire to the prime. (A cable release helps, but is not necessary.)

Here are the photos from the high .030" location:

Here are the photos taken with the level pan location:

Here are the photos with the low pan location:

I was not expecting the difference between the .030" vent and the rest. I thought the .030" position would be the equal of the others.

I am beginning to think that one can have a vent too high. But it's possible that a high vent can be made to work if the shooter uses more prime. Perhaps a level or low vent can produce a good flame front through the vent with less powder, while a high vent needs a larger amount. If that would be the case, then maybe the high vent can work, it's just less efficient with powder????

Maybe it's the angle at which the flame enters the vent. Would a counter sink angled from below make a difference?

This test does make me doubt the effect of convection on flint ignition.

Regards,

Pletch

As I've mentioned before, I think that the strong forces involved with a pile of black powder exploding are far too strong to allow convection, or the idea of rising heat affect a flintlocks ignition.

The results of your experiment seem to suggest that rather than the "heat rising" theory what we are seeing is similar to a "Micro Burst".

Micro Bursts are the rapid downward movement of wind in a thunderstorm. When that downward moving air hits the ground it blasts outward, parallel to the surface blowing down houses, trees and anything else that gets in its way.

With exploding powder in a flintlocks pan a lot of the blast goes out sideways and up but the force that is going downward towards the pan can't move the pan so instead it blasts out sideways, like a Micro burst.

If this is happening, not only the flame that normally is traveling sideways but the added blast of flame that was deflected from a downward direction to a sideways direction is hitting the barrel and the vent.

It's just a theory but your photos would seem to support it.

Your pictures are also screwing up a lot of "common knowledge". Keep up the good work. :grin:

The results of your experiment seem to suggest that rather than the "heat rising" theory what we are seeing is similar to a "Micro Burst".

Micro Bursts are the rapid downward movement of wind in a thunderstorm. When that downward moving air hits the ground it blasts outward, parallel to the surface blowing down houses, trees and anything else that gets in its way.

With exploding powder in a flintlocks pan a lot of the blast goes out sideways and up but the force that is going downward towards the pan can't move the pan so instead it blasts out sideways, like a Micro burst.

If this is happening, not only the flame that normally is traveling sideways but the added blast of flame that was deflected from a downward direction to a sideways direction is hitting the barrel and the vent.

It's just a theory but your photos would seem to support it.

Your pictures are also screwing up a lot of "common knowledge". Keep up the good work. :grin:

"The problem with LOW Vents-where its right down at the bottom of the pan is that HEAT rises! Its heat, not flame that ignites the main charge"

While it is true that heat rises, I doubt that if it could be measures there would be little if any difference in the heat from one side of the pan over an arc to the other side upon ignition,it is just to small of an area and the difference between a low and high vent are to small to really be noticable, likely less than the difference between 2f and 3f, maybe someone can set up an experiment in a closet to test this?

"As I've mentioned before, I think that the strong forces involved with a pile of black powder exploding are far too strong to allow convection, or the idea of rising heat affect a flintlocks ignition."

Sounds very reasonable, if you sit on a grenade and it pops off it aint the heat that will scorch your ass.

While it is true that heat rises, I doubt that if it could be measures there would be little if any difference in the heat from one side of the pan over an arc to the other side upon ignition,it is just to small of an area and the difference between a low and high vent are to small to really be noticable, likely less than the difference between 2f and 3f, maybe someone can set up an experiment in a closet to test this?

"As I've mentioned before, I think that the strong forces involved with a pile of black powder exploding are far too strong to allow convection, or the idea of rising heat affect a flintlocks ignition."

Sounds very reasonable, if you sit on a grenade and it pops off it aint the heat that will scorch your ass.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

As your tests suggest, and you surmise, my fowler has the TH set at .030" above the pan, and my gunmaker recommended using a full pan of powder for fastest ignition. It does work faster as observed by me, and now suggested by your test. I also agree, and have stated, that I am known to be " frugal", and am not yet comfortable using so much priming powder in a pan as required in my fowler. Since I have plenty of 4F and 3F powder on hand, I am not likely to run short of priming powder in the next couple of year, however.

With my .50 cal. rifle, the touch hole splits the line along the top of the pan. I use less priming powder in the pan- about half full- but bank it towards the outside with a trick of powder along the entire bottom of the pan right up to and UNDER the TH. I found this gave my rifle the fastest ignition. If I put too much powder in that pan, or if I bank it up to the TH, ignition is slowed, by comparison.

Some Frizzens are seen in the pictures rebounding back during the ignition of the priming powder. That has to force the flame to travel sideways, contributing to what Jim describes as akin to a micro burst. Some frizzens don't open up very far, during the ignition phase, and the bottom of the frizzen is forcing some of the flame sideways in those cases, too. My Cochran lock actually has a beveled relief in the bottom of the frizzen yo angle flame upwards to ward the barrel and TH. This same kind of relief is common to other locks, as well.

With my .50 cal. rifle, the touch hole splits the line along the top of the pan. I use less priming powder in the pan- about half full- but bank it towards the outside with a trick of powder along the entire bottom of the pan right up to and UNDER the TH. I found this gave my rifle the fastest ignition. If I put too much powder in that pan, or if I bank it up to the TH, ignition is slowed, by comparison.

Some Frizzens are seen in the pictures rebounding back during the ignition of the priming powder. That has to force the flame to travel sideways, contributing to what Jim describes as akin to a micro burst. Some frizzens don't open up very far, during the ignition phase, and the bottom of the frizzen is forcing some of the flame sideways in those cases, too. My Cochran lock actually has a beveled relief in the bottom of the frizzen yo angle flame upwards to ward the barrel and TH. This same kind of relief is common to other locks, as well.

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

While I feel that every experiment done provides more knowledge about BP, it also leads to more questions. The rather poor flame front on the .030" vent begs the question why. Since Paul uses more prime with the high vent, I plan to rerun the pics and compare the flame front with a charge from my normal shooting equipment. My pan charger is advertized to throw 3 grains. That should be a significant increase in priming over the 3/4 grain used in the earlier pics. I'll do all three pan levels again. While I still believe flame front speed trumps the "heat rises theory", we should be able to see if a difference is noted with larger amounts of prime.

I'll work on the photography this evening. Who knows, maybe there is a MB article buried in this somewhere.

Regards,

Pletch

I'll work on the photography this evening. Who knows, maybe there is a MB article buried in this somewhere.

Regards,

Pletch

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

You let me know when you film a flame going downward, without an air assist. Heat does rise, but it also goes outward, too. In fact, it goes anywhere it can grab " Free air". Fire, is after all an oxidation process, that requires materials to be heated to their flash point to convert to gases that burn. :hatsoff:

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

Cute! :rotf:

Do you think gravity had a bit to do with that, Larry???

Do you think gravity had a bit to do with that, Larry???

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

paulvallandigham said:Cute! :rotf:

Do you think gravity had a bit to do with that, Larry???

Paul,

I think any ignition in air travels 360 deg from the ignition point unless blocked by a solid -like the side of a barrel, the pan, pan fence, etc. I suppose one could place 50gr of powder in a tissue bag, suspend on a string, and ignite with a match. My speculation is that we would get a 360 deg flame front in all directions.

Regards,

Larry

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 87

I was talking about the heat rising, not the flame, and we seemed to get off track. Of course fire is going to spread in a full sphere, unless blocked. But if you light a match, or candle, the flame goes upward.

I smoked a pipe for more than 25 years, and I am very aware what it takes to get HEAT to travel downward.

I smoked a pipe for more than 25 years, and I am very aware what it takes to get HEAT to travel downward.

Larry Pletcher

50 Cal.

- Joined

- Jul 27, 2006

- Messages

- 1,313

- Reaction score

- 67

The photos here are from last night's session. I tried a number of methods and finally decided to prime the three vent levels as I do my rifle. I have been working with a new Lancaster .54 with a Chambers lock and a Rice barrel. The rifle has already become my favorite. It uses a WL liner drilled to 1/16". I prime this rifle with a pan charger that is advertised to throw 3 grains. It actually throws a bit less. The Chambers lock has a large pan, so I use 2 plunger charges - one against the barrel and another farther out.

I used this priming method on these photos. The high vent was measured at .030" above the pan top. The level position places the center of the hole level with the pan top. (I tried to bisect the hole with a line running across the pan.) The low position places the exterior cone of the vent at the bottom of the pan. Here are the photos of each vent position:

Photo #1 -- High vent (.030" higher than pan)

Photo #2 -- Level vent

Photo #3 -- Low Vent on pan bottom

The photos IMHO make the argument for a level or lower vent position. Draw what ever conclusion you like. Your lock and vent may act differently than pictured here.

If you are a shooter who wants to check your own gun, this photo is not hard too set up. Most digital cameras have sufficient settings to do this. If you can set your shutter and f-stop manually, you can do this. Doing this shot with a full length barrel will result in a dimmer result, but should still work. Don't use flash or too much room light. My settings were f13 and a shutter set to 4 seconds.

Regards,

Pletch

I used this priming method on these photos. The high vent was measured at .030" above the pan top. The level position places the center of the hole level with the pan top. (I tried to bisect the hole with a line running across the pan.) The low position places the exterior cone of the vent at the bottom of the pan. Here are the photos of each vent position:

Photo #1 -- High vent (.030" higher than pan)

Photo #2 -- Level vent

Photo #3 -- Low Vent on pan bottom

The photos IMHO make the argument for a level or lower vent position. Draw what ever conclusion you like. Your lock and vent may act differently than pictured here.

If you are a shooter who wants to check your own gun, this photo is not hard too set up. Most digital cameras have sufficient settings to do this. If you can set your shutter and f-stop manually, you can do this. Doing this shot with a full length barrel will result in a dimmer result, but should still work. Don't use flash or too much room light. My settings were f13 and a shutter set to 4 seconds.

Regards,

Pletch

Similar threads

- Replies

- 15

- Views

- 910

- Replies

- 3

- Views

- 184

- Replies

- 18

- Views

- 750