. I removed a little wood around the lock and it might have helped it some.

Ok, removing wood from around the lock will accomplish nothing but make the panel look bad.

The trick is to remove wood and sometimes metal from

under not around the lock.

First you have to find where and what is keeping the lock from mating with the barrel.

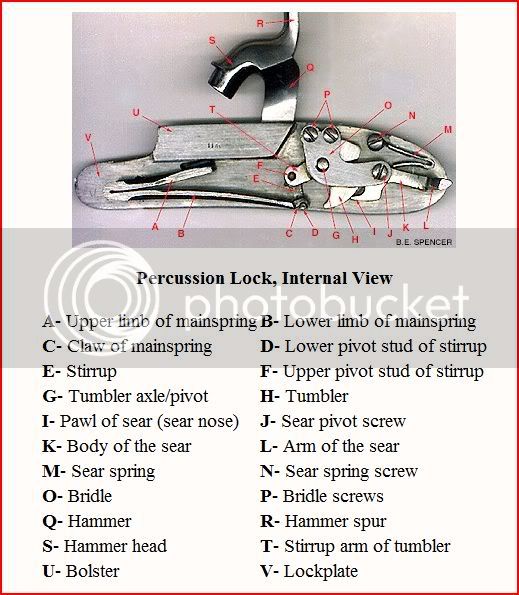

The first place to check is the spring and the guts. When you take the lock out look for any shiny areas where the parts have mashed or burnished the wood.

I cant stress how delicate and precise this operation is. We are talking about just a tiny little bit of material.

Secondly and most important it has to go down square in relation to the barrel. If it is canted one way or another, removal of wood in the wrong place may exacerbate the problem.

Remember you can always remove material but it is pretty hard to add it.

For instance, lets say the culprit is at the topside of the lock, removing wood at the bottom side will only widen the gap and make it even more crooked.

I use candle soot from a burning candle. I just hold the part over close or in the flame, whatever soots it up best. Dome use sharpie markers or even lipstick.

Remember what I said about whats under the lock not around it. You do not want to widen the gap between the metal and wood that's around the lock.

So you have to pay real close attention to understand just what the inlet marks are telling you.

A small chisel, emery finger nail file stick, exacto blade or even a properly shaped sharpened nail can be used to remove the colored imprints. Delicately scrape them away.

Once that's removed mark and repeat. Since you have so little to remove I would screw the lock down each time to make the imprint. It needs to be tight like you normally would install it but not "Hillbilly Tight" as that could warp the plate.

When all else fails...You can always apply a small bead of automotive high temp Black RTV gasket to the bolster. Wipe away the excess and it's pretty much invisible. That will at least keep you from blowing the lock off.