- Joined

- Jun 17, 2019

- Messages

- 8,509

- Reaction score

- 10,000

Thanks for the mention of Bronze Wool. I never liked steel wool much; I'll try to remember this next time I have to finish something.Love the fiish! It is what I strive for on a project!

Thanks for the mention of Bronze Wool. I never liked steel wool much; I'll try to remember this next time I have to finish something.Love the fiish! It is what I strive for on a project!

There’re kits but like gun kits there’re a base for lots of hand work. They give you the stuff for a raw frame. That then needs to be shaped. Follow up with planks made from thin strips of wood, 1/16 to 1/8 inch thick 1/4 to 1/2 inch wide.They are beautiful, do you use kits or are they scratch built?

Jim Kibler recommends it.What's the opinion on laurel mountain forge permalyn sealer?

Got any before and during photos? I can't believe you made those works of art from stir sticks.

Got my vote!Hi,

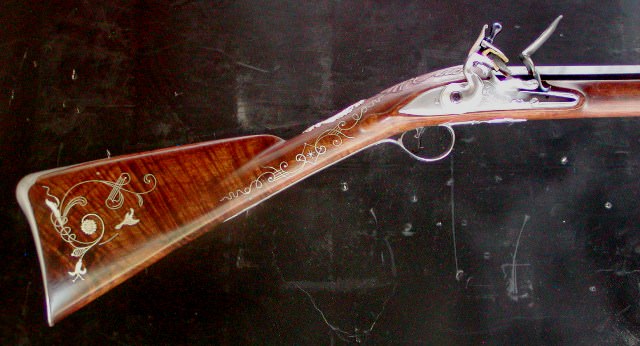

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

Occasionally, I make cased pistols with the accessories.

And once in a while I dabble in the 17th century.

Nice work Scot!

dave

Enter your email address to join: