fantasticHey, Guys, I build railroad cars out of coffee-stirrers - does that count for anything?

View attachment 140533

View attachment 140534

View attachment 140535

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tried and True Danish Oil versus Boiled Linseed Oil finish--question on application

- Thread starter K_P

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Most of my customers like a matte finishWhich glossines(?) version do you use? Do you use the gloss version for everything, and then rub it down to a satin finish if desired?

The Appalachian

Feral American

- Joined

- Jan 26, 2022

- Messages

- 861

- Reaction score

- 1,630

No....Dude.A bit snarky, aren't we?

Nice work, Appalachian, but getting your panties in a twist and attacking a respected, well established member doesn't reflect well.

I didn't attack anyone. I've addressed an attempted insult, defended my methods, and responded to a call out by your "well established member". If you paid attention, snarky happening is what got that ball rolling in the first place.

And, my panties are FAR FAR FAR from being twisted yet.......

The Appalachian

Feral American

- Joined

- Jan 26, 2022

- Messages

- 861

- Reaction score

- 1,630

As I've already explained it's been 30 years since I built a traditional muzzleloader. Yes, I have pictures of finished gunstocks using my BLO method, but last I checked folks get fussed at for posting non traditional firearms here.Very nice WIP photographs. Do you happen to have any of finished gun stocks using an oil finish?

I digress though, probably less fussed at than for defending one's methods by so called pros with opinions on stock finishes..

- Joined

- Mar 13, 2020

- Messages

- 7,532

- Reaction score

- 21,154

- Location

- On the Border in Idaho looking at BC

Twisted Knickers?

The Appalachian

Feral American

- Joined

- Jan 26, 2022

- Messages

- 861

- Reaction score

- 1,630

Hi,

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

There's no doubt you do exquisite work Dave, never implied you didn't.

My gun work for the past 45 of nearly 60 years is just what I do for fun, in my spare time when I have it. A hobby to blow money on, if nothing else. You should see the houses I've built, the concrete I've poured, the landscaping I've done, the clear cuts I've cleared, the power stations I've welded on, the bridges I've repaired, the commercial doors I have hanging in US Embassies, the semi truck cabs I've welded on and painted. And that's just the high spots. Unfortunately my hard labor days are over. Fortunately my family is grown and supporting themselves now.

I like gun work better than any of the above, and can only hope my next 30 or 40 years will be enjoying my new shop and turning out a few nice flinters for folks to enjoy long after I'm gone. I've felt the calling back to the 18th century, which is why I signed up for this forum. I'm here to learn, mainly history not so much methods, but I'm willing to help others if they're asking.

May I suggest a truce........

- Joined

- Mar 13, 2020

- Messages

- 7,532

- Reaction score

- 21,154

- Location

- On the Border in Idaho looking at BC

Appalachian, may i suggest that your work is wonderful, your life achievements are outstanding and impressive.

it is the thickness of your skin and attitude that some here have questioned. attacking Dave because of a perceived slight is a sure way to achieve that exalted position of Ignore here.

you have alot to contribute here. take a deep breath and consider the real possibility that you and Dave could most likely be fast friends in a real world setting. i know i would love the chance to meet and work alongside both of you.

it is the thickness of your skin and attitude that some here have questioned. attacking Dave because of a perceived slight is a sure way to achieve that exalted position of Ignore here.

you have alot to contribute here. take a deep breath and consider the real possibility that you and Dave could most likely be fast friends in a real world setting. i know i would love the chance to meet and work alongside both of you.

- Joined

- Aug 6, 2005

- Messages

- 7,128

- Reaction score

- 5,426

Got any before and during photos? I can't believe you made those works of art from stir sticks.

I have dozens of building pics, but I'm aware that this is a gun forum, and not a train forum. Can I send you email shots? More than happy to do that, me. BTW, the stir sticks from the three most common suppliers just happen to be 3.5 and 5 inches in 1/20.3 scale - the MoW van - and 6" in 1/19th - the yellow caboose scale. The reefer was built from scrap bits of styrene - trucks were converted, though - THAT is in 1/32nd scale, AKA Gauge 1.

- Joined

- Jul 8, 2019

- Messages

- 3,279

- Reaction score

- 5,987

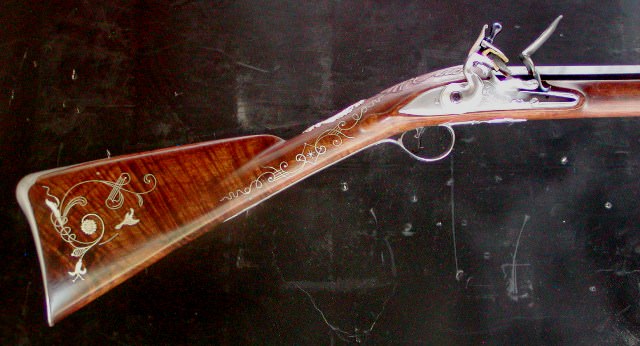

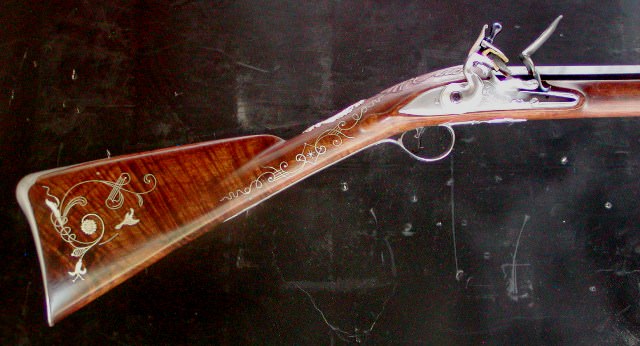

Beautiful work! Where did you learn to engrave so well?Hi,

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

Occasionally, I make cased pistols with the accessories.

And once in a while I dabble in the 17th century.

Nice work Scot!

dave

DuncNZ

54 Cal.

As much as my ships View attachment 140544View attachment 140545View attachment 140546

View attachment 140544View attachment 140545View attachment 140546

[/QUOTE]

How many guns and muskets on board ?

[/QUOTE]

How many guns and muskets on board ?

Top is Rattlesnake, privateer from 1780. Eighteen guns, four pounders, second is Golden Hind, sort of. We don’t have plans of Golden Hind, so this is a ‘typical’ sixteenth century English galleon, eight guns. Last is Bellona English ‘74 1760- 1816. Twenty eight 24 pounders, twenty eight 12s, eighteen 9s. This is the way she looked at time of ARW.

- Joined

- Nov 26, 2005

- Messages

- 5,246

- Reaction score

- 11,025

Hi

Appalachian we don't need a truce, we need to establish friendship. This forum is a good place populated by good people and some that have strong opinions. In my case, I don't tell people what to do. I inform them about what I do and why I do it that way. Like you, I don't care if they follow my advice or not. I have a lot of experience building more than 80 guns over 3 decades and I share those experiences all the time with many, many images, which are very important to establishing credibility and enabling people to judge if a method likely will work for them, or not. Think about it, most people don't read long posts but they do like to view pictures, which is one of the key strengths of an internet forum. With respect to stock finishes, what could be more important than a discussion accompanied by good images? But there are weaknesses too as you put very well. We do need to be skeptical of information on the internet. And that is why for most of the guns I showed above, I posted the complete building process on this site and the American Longrifles site. Folks can see the whole work, warts and all because I hide nothing. If I screw up, I show it and then how I fix it, which often is of more value to forum members than what we do right. My late wife, Gail, and I posted a thorough tutorial on the ALR site showing how to make a historically correct English pistol case. There are internet and you tube sites that show making cases but none I've seen care much for authenticity. If someone wants to make a case but not with all the details we show, fine, but they at least know those details. Also, I don't hide my identity. People know who I am, many attended seminars and demos I've given at Dixon's Gunmakers Fair over the years and will again this summer in Kempton, PA, where I will be demonstrating how to cast those sculpted inlays, how to shape the wrist and lock panels of stocks, and how to make a historically correct English fowler. I am very committed to education but not preaching.

dave

Appalachian we don't need a truce, we need to establish friendship. This forum is a good place populated by good people and some that have strong opinions. In my case, I don't tell people what to do. I inform them about what I do and why I do it that way. Like you, I don't care if they follow my advice or not. I have a lot of experience building more than 80 guns over 3 decades and I share those experiences all the time with many, many images, which are very important to establishing credibility and enabling people to judge if a method likely will work for them, or not. Think about it, most people don't read long posts but they do like to view pictures, which is one of the key strengths of an internet forum. With respect to stock finishes, what could be more important than a discussion accompanied by good images? But there are weaknesses too as you put very well. We do need to be skeptical of information on the internet. And that is why for most of the guns I showed above, I posted the complete building process on this site and the American Longrifles site. Folks can see the whole work, warts and all because I hide nothing. If I screw up, I show it and then how I fix it, which often is of more value to forum members than what we do right. My late wife, Gail, and I posted a thorough tutorial on the ALR site showing how to make a historically correct English pistol case. There are internet and you tube sites that show making cases but none I've seen care much for authenticity. If someone wants to make a case but not with all the details we show, fine, but they at least know those details. Also, I don't hide my identity. People know who I am, many attended seminars and demos I've given at Dixon's Gunmakers Fair over the years and will again this summer in Kempton, PA, where I will be demonstrating how to cast those sculpted inlays, how to shape the wrist and lock panels of stocks, and how to make a historically correct English fowler. I am very committed to education but not preaching.

dave

- Joined

- Mar 13, 2020

- Messages

- 7,532

- Reaction score

- 21,154

- Location

- On the Border in Idaho looking at BC

well, Dave it is plain to see that if you keep practicing you will be able to produce an acceptable product someday!Hi,

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

Occasionally, I make cased pistols with the accessories.

And once in a while I dabble in the 17th century.

Nice work Scot!

dave

man o' man what beauty! i think i just saw my entire collection of builds slinking off into a dark corner.

don't know if your work inspires me or makes me despair of ever being satisfied with my own efforts!

- Joined

- Jul 8, 2019

- Messages

- 3,279

- Reaction score

- 5,987

Your work is on a level that the greater majority of builders can only dream about. I have never engraved any metal but your work is exquisite. Your ability is varied, mine not so much. I do like my finished product to look nice but find everything I do I find fault with? I am not a rifle builder mostly furniture although I have put kits together for a few people and work on rifles/pistols. I don't have the time nor talent to turn out work as complex as yours. As far as other people showing pictures of their work, good luck! After seeing your work I doubt many will post pictures. LOL!Hi,

When someone posts a method and implies it is "THE" way to do something, be skeptical. There are always multiple ways to do any task and meet any objective. I also wish that folks describing their favorite stains and finishes would post photos of their work. That way readers can judge if the methods fit their needs. I've used many different finishing products over the years but homed in on 2 based on my experience. Both use tung oil. The first is 25% raw tung oil, 25% urethane varnish, and 50% mineral spirits. I used this mix while living in SE Alaska because I could not easily get polymerized tung oil, my favorite finish, and developed an excellent alternative that was more readily available. It stood up very well to the harsh conditions of rain, salt air, and sea spray encountered during hunting in that environment. My second and favorite finish is Sutherland-Wells polymerized tung oil. I use it because it can match the appearance of any original finish, which were mostly linseed oil and copal varnish mixes, but has superior weather resistance to linseed-based finishes and it does not darken over time. Tung oil is ancient and was sometimes referred to in centuries past as "China" oil. I doubt 17th-19th century European and American gun makers ever used it. They used linseed oil, not because it made a great finish, but it was cheap and available. There is also evidence from some Lehigh Valley rifles, that some gun makers sealed stocks first with shellac and then applied linseed oil varnish on top. Anyway, I substitute tung oil for linseed because it has superior qualities and I can make its appearance match any of my objectives. Every stock I finish is a different story because of the serendipitous nature of wood, the species of wood, and my objectives for the appearance of the gun. Sometimes I apply just the finish, sometimes I tint it with oil soluble dyes or alkanet root, some times I apply the finish with sandpaper to create a grain filling slurry on the surface, sometimes I apply a few coats for a low sheen, and sometimes I let finish build up so I can rub it back with rottenstone and create the glassy smooth finishes found on Purdeys and Holland & Hollands . Each stock is different.

dave

- Joined

- Aug 16, 2021

- Messages

- 273

- Reaction score

- 334

Thank you! My interest in guns is now mostly black powder, but I have studied and appreciated for years the work of those that build the “classic” Ruger #1, M98 or other quality bolt rifle. A custom stocked rifle like that is a work of art. I am looking forward to learning some of your guild secrets and apply them to several BP projects that are waiting on me.a lot of guild guys including me want to be helpful. Im not wanting to take my so called "secrets of stock making to my grave". lol

- Joined

- Aug 16, 2021

- Messages

- 273

- Reaction score

- 334

Now thats cool. I find myself looking for likley places to put a G scale track in my yard....thanks for fanning THAT flameHey, Guys, I build railroad cars out of coffee-stirrers - does that count for anything?

View attachment 140533

View attachment 140534

View attachment 140535

- Joined

- Aug 16, 2021

- Messages

- 273

- Reaction score

- 334

Those ships are amazing. Do you build for museums or just for your own enjoyment?

Just me, they are no way near museum quality

They are beautiful, do you use kits or are they scratch built?

- Joined

- Jun 17, 2019

- Messages

- 8,509

- Reaction score

- 10,001

Interesting. Most ML guns aren't exposed to the raw weather very much. A few days a year for deer, turkey, etc., then carefully stored & cleaned. I don't imagine the stock has to be able to withstand being strapped to a space shuttle, but whatever finish guys like, it's a free country. Thanks for the tip on the Waterlox.One of the best oils I have found to use. Several guild members and myself use it. Also this and the "stop loss bag" one can keep finish in it for a long long time and it wont dry up it's like an IV bag at the hospital. One can get both of these at "woodcraft" on the internet. I hope this helps

Similar threads

- Replies

- 6

- Views

- 327