awesome manRecently started dabbling in horn making. This is my first one. Everybody says it's fantastic craftsmanship. I'm humbled.

You, do any powderhorns, "dave"?

View attachment 140480View attachment 140481View attachment 140482View attachment 140483

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tried and True Danish Oil versus Boiled Linseed Oil finish--question on application

- Thread starter K_P

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

very very great work"dave"...do you build tomahawks?View attachment 140477View attachment 140478

- Joined

- Mar 13, 2020

- Messages

- 7,532

- Reaction score

- 21,154

- Location

- On the Border in Idaho looking at BC

He certainly established something.Well, I have to say that Appalachian Hunter has established his bonafides!

- Joined

- Nov 26, 2005

- Messages

- 5,246

- Reaction score

- 11,025

Hi,

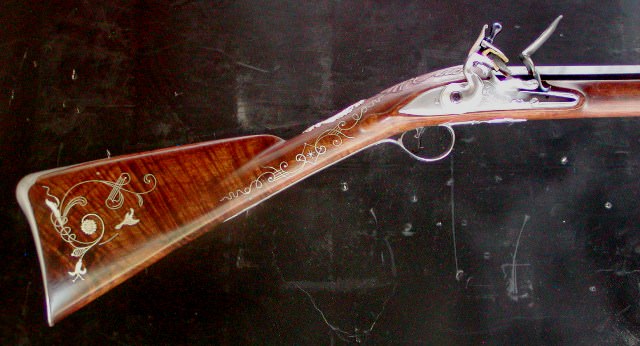

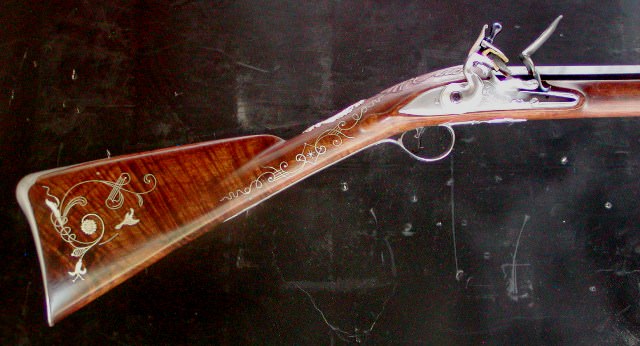

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

Occasionally, I make cased pistols with the accessories.

And once in a while I dabble in the 17th century.

Nice work Scot!

dave

I dabble in other things but mainly just build muzzleloading guns and have contributed to this site for over a decade.

Occasionally, I make cased pistols with the accessories.

And once in a while I dabble in the 17th century.

Nice work Scot!

dave

- Joined

- Jul 8, 2019

- Messages

- 3,279

- Reaction score

- 5,987

Tung oil,Danish oil, shellac and and any other types of finish needs proper preperation before using. I love Tung oil , it is easy to repair damage and does have some water resistance . The down side to me is it does little to protect the stock from natural wear and tear. Remington had a polymer finish they used years back called Zytel. It was the worst finish I ever dealt with. although it was hard and water resistent it would get a white cloudy film under it if water ever got under it via a chip which chipped easy. If one is leaning toward this type of finish you might want to reconsider.Hi,

When someone posts a method and implies it is "THE" way to do something, be skeptical. There are always multiple ways to do any task and meet any objective. I also wish that folks describing their favorite stains and finishes would post photos of their work. That way readers can judge if the methods fit their needs. I've used many different finishing products over the years but homed in on 2 based on my experience. Both use tung oil. The first is 25% raw tung oil, 25% urethane varnish, and 50% mineral spirits. I used this mix while living in SE Alaska because I could not easily get polymerized tung oil, my favorite finish, and developed an excellent alternative that was more readily available. It stood up very well to the harsh conditions of rain, salt air, and sea spray encountered during hunting in that environment. My second and favorite finish is Sutherland-Wells polymerized tung oil. I use it because it can match the appearance of any original finish, which were mostly linseed oil and copal varnish mixes, but has superior weather resistance to linseed-based finishes and it does not darken over time. Tung oil is ancient and was sometimes referred to in centuries past as "China" oil. I doubt 17th-19th century European and American gun makers ever used it. They used linseed oil, not because it made a great finish, but it was cheap and available. There is also evidence from some Lehigh Valley rifles, that some gun makers sealed stocks first with shellac and then applied linseed oil varnish on top. Anyway, I substitute tung oil for linseed because it has superior qualities and I can make its appearance match any of my objectives. Every stock I finish is a different story because of the serendipitous nature of wood, the species of wood, and my objectives for the appearance of the gun. Sometimes I apply just the finish, sometimes I tint it with oil soluble dyes or alkanet root, some times I apply the finish with sandpaper to create a grain filling slurry on the surface, sometimes I apply a few coats for a low sheen, and sometimes I let finish build up so I can rub it back with rottenstone and create the glassy smooth finishes found on Purdeys and Holland & Hollands . Each stock is different.

dave

If you seal the wood and use Danish oil you can correct a proplem that may arise . It is a little harder than Tung oil and is the only reason I rarely use Tung oil on a project like a rifle stock. I will admit you do have a large window of options with Tung oil.

- Joined

- Aug 16, 2021

- Messages

- 273

- Reaction score

- 334

Which glossines(?) version do you use? Do you use the gloss version for everything, and then rub it down to a satin finish if desired?One of the best oils I have found to use. Several guild members and myself use it. Also this and the "stop loss bag" one can keep finish in it for a long long time and it wont dry up it's like an IV bag at the hospital. One can get both of these at "woodcraft" on the internet. I hope this helps

user 34300

54 Cal.

- Joined

- Nov 25, 2019

- Messages

- 1,743

- Reaction score

- 2,125

Remington had a polymer finish they used years back called Zytel.

I used to use a lot of that kind on thing. There were a couple that I could get and worked about the same, Fullerplast and Glasscote. You could prep the stock, no filler. Warm it up in a hot box. Then spray multiple coats one after the next in a few minuets. One and done. After it stopped out gassing it was cut back with 600 grit wet dry paper and rubbed out with automotive rubbing compound. It could be made to look like a Weatherby or almost like a traditional finish. Manufacturers love it because it is fast and extremely durable. It is also highly toxic. Proper PPE is a must. From what I gather it is the same stuff as Imron. Anyway, it would be difficult to make look right on a ML.

Remington polymer finish? Some the nastier paint removers, like "Aircraft" will take it off. The newer safer one do little. It is easier, for me, to sand it off.

I used to use a lot of that kind on thing. There were a couple that I could get and worked about the same, Fullerplast and Glasscote. You could prep the stock, no filler. Warm it up in a hot box. Then spray multiple coats one after the next in a few minuets. One and done. After it stopped out gassing it was cut back with 600 grit wet dry paper and rubbed out with automotive rubbing compound. It could be made to look like a Weatherby or almost like a traditional finish. Manufacturers love it because it is fast and extremely durable. It is also highly toxic. Proper PPE is a must. From what I gather it is the same stuff as Imron. Anyway, it would be difficult to make look right on a ML.

Remington polymer finish? Some the nastier paint removers, like "Aircraft" will take it off. The newer safer one do little. It is easier, for me, to sand it off.

Tru oil is all I use!. I thin it with paint thinner so I can spray it with a touch up gun. I put a coat on without runs, let it dry to tacky and in that way I apply 5 to 6 coats. Each coat melds with the rest to make one thick coat. I set it aside until I can no longer smell it, 2 weeks at least. After it can be rubbed out or polished without breaking through layers. Then wax it.

I did a friends new stock I made for his Springfield 03-A3 30 years ago and it has been carried to many states to hunt in all weather and it still looks new.

I was taken aback when he came with a plank of wood and his rifle. It took me weeks before I took tools to it. That piece of wood was $300!

I did a friends new stock I made for his Springfield 03-A3 30 years ago and it has been carried to many states to hunt in all weather and it still looks new.

I was taken aback when he came with a plank of wood and his rifle. It took me weeks before I took tools to it. That piece of wood was $300!

- Joined

- Aug 6, 2005

- Messages

- 7,128

- Reaction score

- 5,426

He repeated the test. Soaked with Lindseed, and wiped off. Let stand for a week. Buffed. One thin coat every day for a week. Then once a week for a month, then one a month for a year.

I've been saying that here for years....................

- Joined

- Aug 6, 2005

- Messages

- 7,128

- Reaction score

- 5,426

Hey, Guys, I build railroad cars out of coffee-stirrers - does that count for anything?

- Joined

- Mar 13, 2020

- Messages

- 7,532

- Reaction score

- 21,154

- Location

- On the Border in Idaho looking at BC

which coffee company do you use? i'm wanting stock in that one!

on my list of lusts, flintlocks being second on the list, RR is third!

will let one guess what is number one.

on my list of lusts, flintlocks being second on the list, RR is third!

will let one guess what is number one.

A bit snarky, aren't we?

Nice work, Appalachian, but getting your panties in a twist and attacking a respected, well established member doesn't reflect well.

Got any before and during photos? I can't believe you made those works of art from stir sticks.Hey, Guys, I build railroad cars out of coffee-stirrers - does that count for anything?

View attachment 140533

View attachment 140534

View attachment 140535

As much as my shipsHey, Guys, I build railroad cars out of coffee-stirrers - does that count for anything?

View attachment 140533

View attachment 140534

View attachment 140535

Very nice WIP photographs. Do you happen to have any of finished gun stocks using an oil finish?So, pictures are the measure of one's legitimacy on this forum.

Ok....

Having been out of traditional muzzleloaders for the past 30 years I have none of finished work, but I'm back into it, and currently building a Tennessee percussion as I've posted elsewhere.

I do have lots of pictures of what this forum doesn't allow posted, mostly walnut Marlin's I've rebuilt or refinished, not to mention scratch built synthetic stocks for long range centerfire rifles. That's been the bulk of my past 3 decades.

the Tennessee in progressView attachment 140469View attachment 140473View attachment 140474

View attachment 140464

Yes. I rub it down after I get the desired finish. Im leaving but when I get back I will give you an in depth description when I get back. I finish up with a nice matte finish and very very durable finish. If I dont get back to you then remind me. Thanks KabulrocksWhich glossines(?) version do you use? Do you use the gloss version for everything, and then rub it down to a satin finish if desired?

awesome

a lot of guild guys including me want to be helpful. Im not wanting to take my so called "secrets of stock making to my grave". lolWhich glossines(?) version do you use? Do you use the gloss version for everything, and then rub it down to a satin finish if desired?

Similar threads

- Replies

- 6

- Views

- 327