chawbeef

40 Cal.

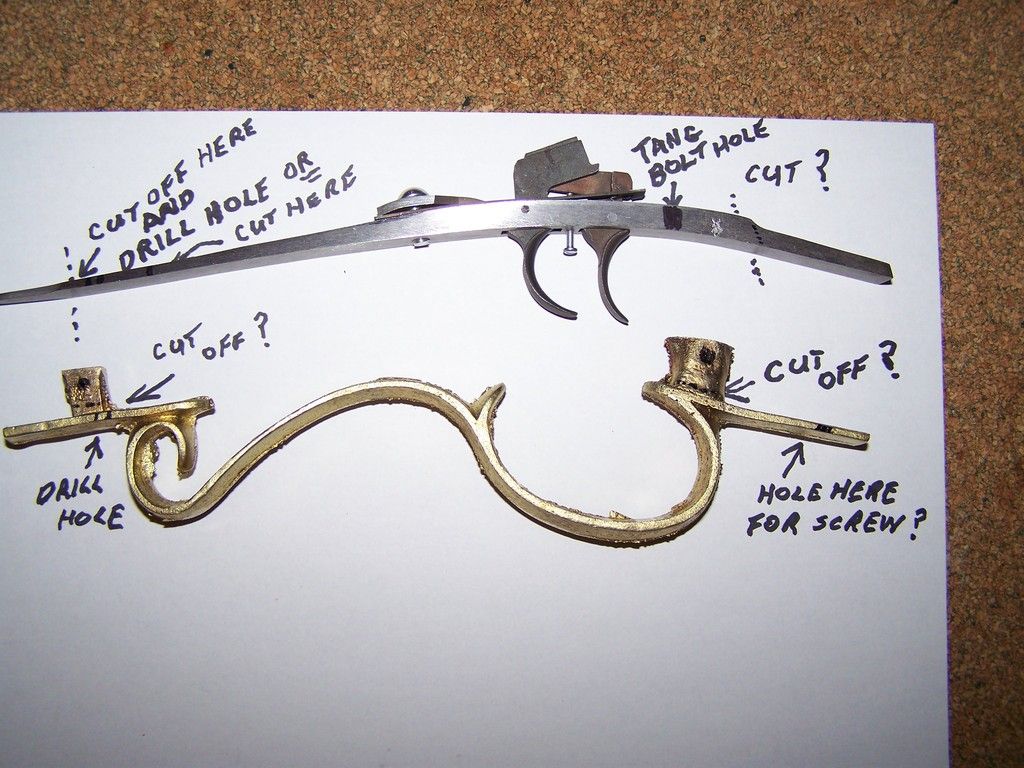

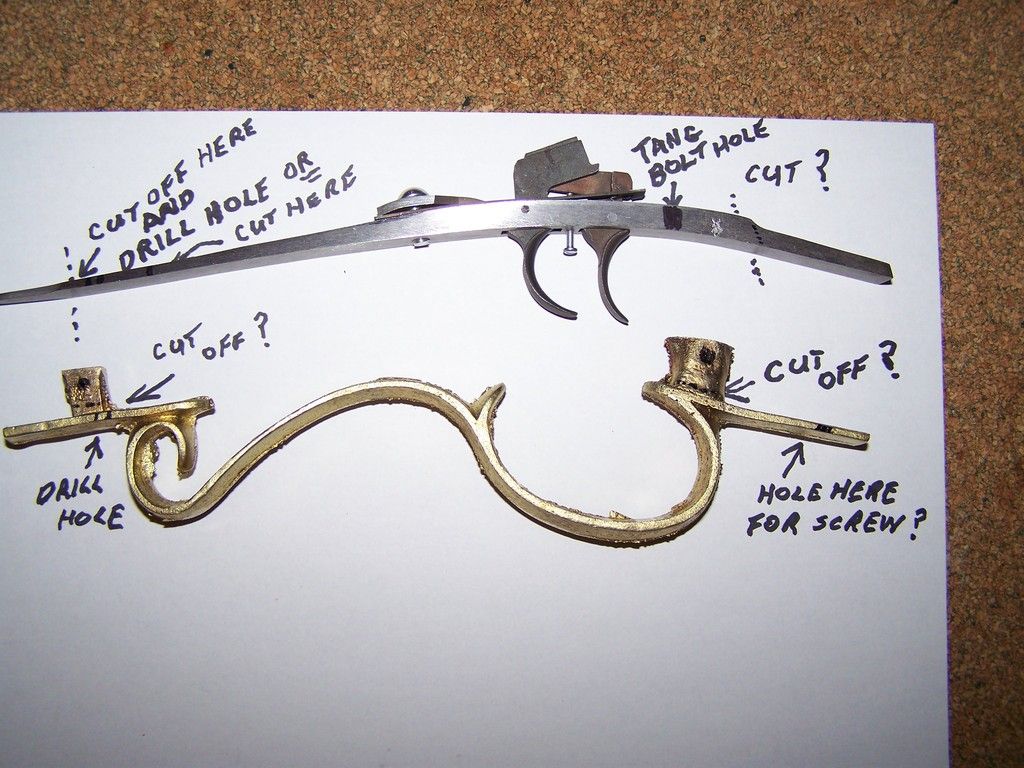

Hi all. Since my trigger plate is the same length as my guard, I am wondering if I should shorten the plate and fasten the guard at the rear with a screw thru both guard and plate (remove the lug) or cut the plate further forward and leave the lug and pin it.

Also, I think I may have to cut off the front lug as it looks like it will interfere with the tang bolt.

This being my first build I am a little intimidated at this point...............Daniel

Also, I think I may have to cut off the front lug as it looks like it will interfere with the tang bolt.

This being my first build I am a little intimidated at this point...............Daniel