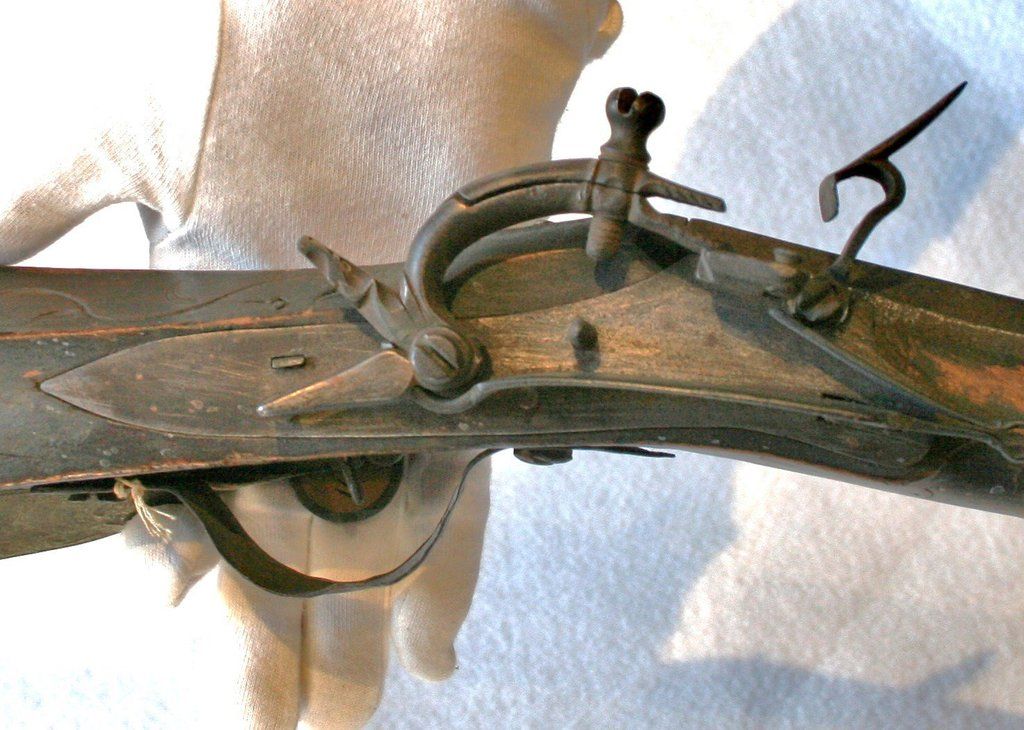

It is very obvious from the photos that none of the steel parts have ever been oiled.

As they were never oiled I don't know whether to blame the rust on the builder failing to neutralize the browning agent or it is just due to a lack of proper care.

Had a good coat of oil, even just plain old automotive engine oil been applied to the metal surfaces they would be in far better shape than they are now.

A short comment about browning and blueing:

Both browning and bluing protect the steel under the surface buy forming a layer of a special hard rust.

By itself, the rusty layer will not provide any protection at all. In fact, it will continue to rust unless it is oiled.

Rust will absorb the oil and hold it against the metal sublayer and it is this oil that keeps the oxygen and moisture in the air from getting access to the metal.

If oxygen and moisture can't get to the metal, further rusting will not happen.

From what I see, a through scouring with #00 steel wool on all rusted surfaces to remove all loose rust is needed.

Follow this with a through coating of motor oil on all surfaces, rusted or unrusted on all of the steel parts.

Following this, hand rub a coating of Tung or Linseed oil into all of the wood surfaces of the stock. Right now, the wood looks very dry.

PS: I can see why this rifle was so expensive.

There are no off the shelf parts for this gun and everything, (other than the barrel?) was hand made.

In that time he has had personal problems and I have not pushed. But, maybe time has come to insist just so I can get my $1,000.00 worth of parts back. From now on I'll get an estimated completion date and make a few calls along the way to assure it is in the works.

In that time he has had personal problems and I have not pushed. But, maybe time has come to insist just so I can get my $1,000.00 worth of parts back. From now on I'll get an estimated completion date and make a few calls along the way to assure it is in the works.