You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blacksmiths, lets see yer stuff!

- Thread starter blacksmithman64

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- May 22, 2008

- Messages

- 640

- Reaction score

- 1,146

blacksmithman64

50 Cal.

- Joined

- Jan 2, 2007

- Messages

- 1,114

- Reaction score

- 1

that is about the coolest set of flint tools I ever saw! :thumbsup:

skunkskinner

50 Cal.

- Joined

- Aug 10, 2005

- Messages

- 1,107

- Reaction score

- 2

I like your "sporks" Loyd.

skunkskinner

50 Cal.

- Joined

- Aug 10, 2005

- Messages

- 1,107

- Reaction score

- 2

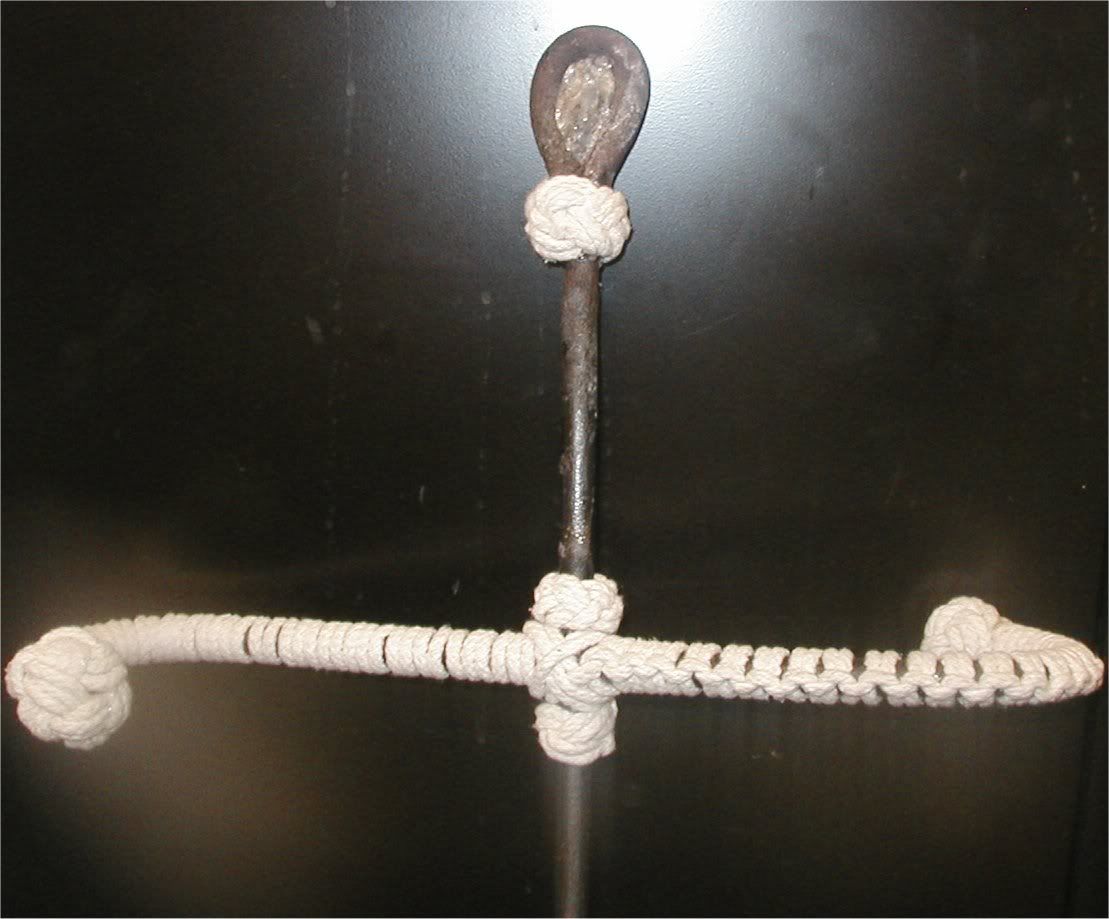

freedom475, what did you wrap your pan brush with? Looks good.

jimmytheshank

40 Cal.

- Joined

- Sep 23, 2007

- Messages

- 472

- Reaction score

- 1

Man! I need a set of those. :shocked2:

- Joined

- May 22, 2008

- Messages

- 640

- Reaction score

- 1,146

Stumblin Wolf said:that is about the coolest set of flint tools I ever saw! :thumbsup:

Thank you very much...I've seen some of your work so a compliment like that really means a lot to me. :hatsoff:

- Joined

- May 22, 2008

- Messages

- 640

- Reaction score

- 1,146

skunkskinner said:freedom475, what did you wrap your pan brush with? Looks good.

Thank you.

I used brass wire to wrap the horse hair broom. It took a little practice and some powerful hurt on the fingers to get them tight as I liked. :haha:

And a nice ring and linked chain on that flint tools set as well!

There is always some "worry" associated with chain made from small wire if you don't somehow weld/solder or "lock" the loops together so that they don't pull apart in use. You did a nice job on that ... double wrap ... of the ends. Tricky thing to do, and keep symetrical/even.

Copper or Brass slug for the the knapping hammer?

And the sporks/awls posted earlier are nice as well.

One thing I have learned is that the smaller the item is that you want to forge up, the harder it is to make it - and have it turn out right. People look at small iron work, and usually think that it should be easier to make. But it is often just the opposite.

Case in point: zigzag canoe awls. I've figured out one way to forge that "zig" in the middle and have it turn out right. But it is easier to do on an awl that is 5 to 8 inches long than it is on one that is 3 to 4 inches long. So I'm still searching for a better way to make them. They were such a "cheap" common trade item that there had to be a much quicker and simpler way to forge them up. So I'm still searching for new ways to make them. The ones with the "bent" zig are easy.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

There is always some "worry" associated with chain made from small wire if you don't somehow weld/solder or "lock" the loops together so that they don't pull apart in use. You did a nice job on that ... double wrap ... of the ends. Tricky thing to do, and keep symetrical/even.

Copper or Brass slug for the the knapping hammer?

And the sporks/awls posted earlier are nice as well.

One thing I have learned is that the smaller the item is that you want to forge up, the harder it is to make it - and have it turn out right. People look at small iron work, and usually think that it should be easier to make. But it is often just the opposite.

Case in point: zigzag canoe awls. I've figured out one way to forge that "zig" in the middle and have it turn out right. But it is easier to do on an awl that is 5 to 8 inches long than it is on one that is 3 to 4 inches long. So I'm still searching for a better way to make them. They were such a "cheap" common trade item that there had to be a much quicker and simpler way to forge them up. So I'm still searching for new ways to make them. The ones with the "bent" zig are easy.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

- Joined

- May 9, 2005

- Messages

- 5,147

- Reaction score

- 26

:bow: the talent on this forum never ceases to AMAZE me! great work guys! ya done good! :thumbsup: thanks fer sharin!................. :hatsoff:

Okay all you black smiths- question time. For some reason there doesn't seem to be that many craftsmen focused on the mountain man era. (refer to the other thread on this forum posted about knives by Rusty).

so.... what about some pure mountain man stuff. No artistic interpretation- just copies of original gear.

1. Butcher knife. I think most folks like the 6" blade more than the 7" so a 6" forged blade with a tapered half tang. The blade should also taper from the front of the tang to the point. There should be pin holes punched in tang- two in front and one in the middle.

2. Spade- what you have looks good.

3. Grub hoe- In the Miller painting "Digging the Cache"- it looks like a modern grub hoe but maybe a little lighter in weight. If grub hoes did double duty in making guttered out log roofs, dug out canoes, etc- maybe a cupped blade.

4. Oval fire steel.

5. Iron fitting on a picket pin for your horse

6. PC tack for horse hardware.

7. A square center bar belt buckle. 1 1/2" 2" maybe 1" for hunting pouch strap.

8. spurs that fit moccasins.

9. sheet iron pots, not tinned.

10. hatchets, axes.

I can't think of anything else right now and I realize some of the stuff I've mentioned is already shown.

so.... what about some pure mountain man stuff. No artistic interpretation- just copies of original gear.

1. Butcher knife. I think most folks like the 6" blade more than the 7" so a 6" forged blade with a tapered half tang. The blade should also taper from the front of the tang to the point. There should be pin holes punched in tang- two in front and one in the middle.

2. Spade- what you have looks good.

3. Grub hoe- In the Miller painting "Digging the Cache"- it looks like a modern grub hoe but maybe a little lighter in weight. If grub hoes did double duty in making guttered out log roofs, dug out canoes, etc- maybe a cupped blade.

4. Oval fire steel.

5. Iron fitting on a picket pin for your horse

6. PC tack for horse hardware.

7. A square center bar belt buckle. 1 1/2" 2" maybe 1" for hunting pouch strap.

8. spurs that fit moccasins.

9. sheet iron pots, not tinned.

10. hatchets, axes.

I can't think of anything else right now and I realize some of the stuff I've mentioned is already shown.

Well, the initial question was about blacksmith

iron work OTHER THAN knives and hawks - since they

often get pictures of them posted. Yeah, I did

break down and include one pic of that sheep shear

knife, but I've tried to keep pics to things other

than knives/hawks.

Here's a pic of some OVAL fire steels - "polished bright".

And a few variations. A friend made the third one

over, and another friend gave me the far right one.

These started my quest to make proper oval strikers

for the fur trade.

The more I look into flint strikers in North

America, the more often I find the Oval flint

striker showing up. From those early trade goods

lists in the 1750's on up through the 1850's. And

we now have some "almost first hand" evidence that

the oval was they type/shape that Lewis and Clark

took on their Voyage of Discovery - almost first

hand. No direct evidence has been found so far to

definitively state what the shape/style of the

strikers were. But in 1811, Clark sent an order

for Trade Goods for his American Fur Company. The

list is almost exactly like the list of "trade

goods" they took on their voyage. And next to the

line for "fire steels" he drew an Oval one - to

make sure that is what he got.

Rex Allen Norman wrote an article in Muzzleloader

Magazine July/August 2007 called "Strike A Light".

He includes a drawing of typical flint strikers for

the Western Fur Trade. Next to the Oval he wrote:

"This may have been the most common style available

to the beaver trappers."

Some more flint strikers. The top two were

recovered from Mohawk Indian village sites - late

1600's and early 1700's.

The middle two are from Seneca Indian village

sites dated to 1650 to 1680. The bottom one

is a Scottish flint striker - yeah, not just

labeled as a Brit or English striker, but

Scottish.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

iron work OTHER THAN knives and hawks - since they

often get pictures of them posted. Yeah, I did

break down and include one pic of that sheep shear

knife, but I've tried to keep pics to things other

than knives/hawks.

Here's a pic of some OVAL fire steels - "polished bright".

And a few variations. A friend made the third one

over, and another friend gave me the far right one.

These started my quest to make proper oval strikers

for the fur trade.

The more I look into flint strikers in North

America, the more often I find the Oval flint

striker showing up. From those early trade goods

lists in the 1750's on up through the 1850's. And

we now have some "almost first hand" evidence that

the oval was they type/shape that Lewis and Clark

took on their Voyage of Discovery - almost first

hand. No direct evidence has been found so far to

definitively state what the shape/style of the

strikers were. But in 1811, Clark sent an order

for Trade Goods for his American Fur Company. The

list is almost exactly like the list of "trade

goods" they took on their voyage. And next to the

line for "fire steels" he drew an Oval one - to

make sure that is what he got.

Rex Allen Norman wrote an article in Muzzleloader

Magazine July/August 2007 called "Strike A Light".

He includes a drawing of typical flint strikers for

the Western Fur Trade. Next to the Oval he wrote:

"This may have been the most common style available

to the beaver trappers."

Some more flint strikers. The top two were

recovered from Mohawk Indian village sites - late

1600's and early 1700's.

The middle two are from Seneca Indian village

sites dated to 1650 to 1680. The bottom one

is a Scottish flint striker - yeah, not just

labeled as a Brit or English striker, but

Scottish.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

blacksmithman64

50 Cal.

- Joined

- Jan 2, 2007

- Messages

- 1,114

- Reaction score

- 1

Mike, would there be any difference in welding tool steel such as files and general run of the mill hot rolled 1020? I have a coal forge and flux with borax on the 1020. Never tried to weld tool steel, wondering about welding those oval strikers if I made them out of files.

And a pic of one of my ... typical ... oval flint

strikers - based on many originals recovered all

around the Great Lakes and on down the Mississippi

River valley. 3 inch by 1 1/2 inch and 1/8 inch thick.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

strikers - based on many originals recovered all

around the Great Lakes and on down the Mississippi

River valley. 3 inch by 1 1/2 inch and 1/8 inch thick.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

Welding tool/spring steel will work pretty similar, but it will come up to welding temp a little bit faster. And it is easier to "burn out" some of the carbon in the steel. Scale tends to form faster/easier.

Several friends that I know make their oval flint strikers out of garage door springs. They clip out a complete ring, weld the ends, stretch the shape out to oval, and then flatten the round stock down. It works for them.

In the end, it is just like welding up chain link. Some like the weld to be on the ends, and some like it in the middle of one side. Personal choice.

I make mine a little differently - to more closely replicate the "mass production" of those originals. Those originals were made in large factories over in Europe, from big sheets of steel received from suppliers who just made STEEL from Wrought Iron, and "stamped" out using water-powered drop hammers. Then cleaned up and heat-treated as usual. Mass Produced in large quantities, and done cheaply enough that they could be sold/traded for almost nothing - even given away to encourage other trading. Yes, some were individually forged/welded up, but large numbers were required for the fur trade. So available technology and manufacturing processes were employed - just like in Trade Knife production. Stamp out the basic shape, and then hand forge to finish. The early version of the "assembly line" was applied, with everybody doing their "one step" in the whole process.

Now, most of this is my personal take on their processes, but the technology/tooling and end products all point toward it. And other people involved in early industrial technology agree.

But I'm still having problems on the final heat-treat of oval fire steels 1/16 inch thick or thinner! That thin steel cools off way to fast on me - even before the quench. And some originals were even thinner - like 1/32th inch thick (or thin as the case may be).

Just my humble thoughts to share, and best used in conjunction with your own research.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

Several friends that I know make their oval flint strikers out of garage door springs. They clip out a complete ring, weld the ends, stretch the shape out to oval, and then flatten the round stock down. It works for them.

In the end, it is just like welding up chain link. Some like the weld to be on the ends, and some like it in the middle of one side. Personal choice.

I make mine a little differently - to more closely replicate the "mass production" of those originals. Those originals were made in large factories over in Europe, from big sheets of steel received from suppliers who just made STEEL from Wrought Iron, and "stamped" out using water-powered drop hammers. Then cleaned up and heat-treated as usual. Mass Produced in large quantities, and done cheaply enough that they could be sold/traded for almost nothing - even given away to encourage other trading. Yes, some were individually forged/welded up, but large numbers were required for the fur trade. So available technology and manufacturing processes were employed - just like in Trade Knife production. Stamp out the basic shape, and then hand forge to finish. The early version of the "assembly line" was applied, with everybody doing their "one step" in the whole process.

Now, most of this is my personal take on their processes, but the technology/tooling and end products all point toward it. And other people involved in early industrial technology agree.

But I'm still having problems on the final heat-treat of oval fire steels 1/16 inch thick or thinner! That thin steel cools off way to fast on me - even before the quench. And some originals were even thinner - like 1/32th inch thick (or thin as the case may be).

Just my humble thoughts to share, and best used in conjunction with your own research.

Mikey - that grumpy ol' German blacksmith out in the Hinterlands

I'm seeing some great work here. Perhaps one of you smiths can direct me to someone willing to make a more period correct turnscrew for me. I'm looking for something like the loop handled version that Pichou pictures from the Wnuck collection. I'd actually be looking for two a longer version such as that pictured and a shorter version for pouch use.

The ones that I see for trade have a shepards crook handle, but every original that I see has a loop handle.

Any takers?

The ones that I see for trade have a shepards crook handle, but every original that I see has a loop handle.

Any takers?

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 28

- Views

- 1K

- Replies

- 12

- Views

- 541

Latest posts

-

-

-

-

-

-

-

-

-

Anybody here proficient in making Plains war shirts? (Need help)

- Latest: Flintlock Fellow