With all of the things that must be considered, a written list of guidelines could end up looking like a giant book so that isn't practical.

The forum's moderators and Claude are the ones who figure out what is OK and what is not.

We don't need a bunch of members appointing themselves as the HC or PC Forum Police and as should be apparent from the 3 pages this topic has become, their comments usually turn into arguments which resolve little or nothing.

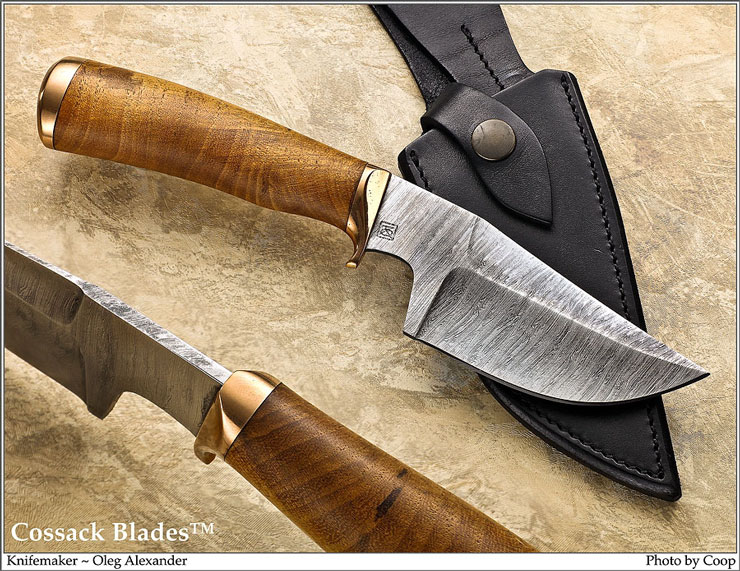

If someone wants one thing that would not be HC or PC it would be using stainless steel for anything.

Stainless steel was not used for anything until after 1913.

The forum's moderators and Claude are the ones who figure out what is OK and what is not.

We don't need a bunch of members appointing themselves as the HC or PC Forum Police and as should be apparent from the 3 pages this topic has become, their comments usually turn into arguments which resolve little or nothing.

If someone wants one thing that would not be HC or PC it would be using stainless steel for anything.

Stainless steel was not used for anything until after 1913.