Mike Brooks said:

No apologies here, I will suggest instead that everyone go out and buy several of these wonderful India made guns. I mean why in the hell shouldn't we run the American gun business out of existence like we have every other business in America....

You might find this from the old "Buckskin Reprot" interesting.

Some might ask why the musket barrel did not simply bulge as this barrel did.

This report seems to follow your previous comments on barrels with bore obstructions bulging rather than failing catastrophically.

Dan

=============

From February 1976 issue The Buckskin Report

Best Barrel Makers Use Quality Steel

John D. Baird

The December 1972 issue of Muzzle Blasts, the monthly publication of the National Muzzle Loading Rifle Association, carried an article, written by Roy Keeler, designed to stress the fact that all muzzleloading guns ought to be proof fired, for the sake of safety. The article showed a picture of a Douglas .45 caliber, 13-16th barrel that had failed with the first shot, using 50 grains of 2fg powder and one .437 patched round ball. That the barrel was flawed is beyond doubt - very likely it was a mill end from a run of steel but whatever the reason, it is unlikely that either the steel producer, the barrel maker or the riflesmith could have discovered the flaw, using normal quality control methods, without proofing the finished barrel.

The article in question was not written to denigrate barrels made by Douglas - it was written to stress the need for prooftesting of all muzzleloading barrels, before putting them into regular service. With that same view in mind, we ran that particular article, verbatim, in our book Who's Who in Buckskins, published in 1973. Hopefully, the article has impressed rifle builders of the need to always proof a new barrel, before sending it out on a new rifle being built for a customer.

In past issues of the Report we have often expressed our position that muzzleloading firearms have to be designed and built with a capability of handling inadvertent abuse - with a strength factor built into the barrel and breech that can handle overloading, improper ball seating, etc. We do not mean to imply that we feel the barrel manufacturer or riflesmith is to be accountable for utter foolishness or stupidity on the part of the shooter, but we do feel that a muzzleloading rifle should carry a safety factor that will help prevent, or reduce damage from, accidents caused by improper use of propellants. High quality steel in rifle barrels, proper design and installation of breeches, proper barrel wall thickness; these are but three different areas where the barrel maker-rifle builder can design safety into a firearm that, by its very nature, can be subjected to abnormal loads and undue pressure.

Nor is it just the inexperienced newcomer to muzzleloading that are prone to make mistakes that could conceivably create a dangerous situation. More experienced shooters, in a moment of thoughtlessness, or carelessness, can create a situation where a burst gun is eminently possible. Such a situation did happen recently, and is the basis for this particular article. We also harbor the hope that this article might restore any faith in the strength and quality of Douglas barrels that was lost on account of our running the article mentioned at the beginning of this account.

Don King, a well known riflesmith who now lives in Big Timber, asked me to come down and look at a barrel he had in his shop. Upon arrival at his establishment I found that he had received from a customer one of the rifles he had built several years earlier. This was a beautiful, .45 caliber fullstock Kentucky flintlock, for which the owner had paid Don a very substantial sum of money to build especially for him. The owner, whose name we won’t mention so as to avoid any embarrassment, had been shooting muzzleloaders since 1948, so he was not a newcomer to our sport.

However, he had not shot his King rifle for some time, but had, instead, been shooting another gun and as a result his powder measure was set for a much larger charge of powder than he would normally use in the King flintlock rifle. Taking the King gun out to shoot, he forgot to change the powder measure back to the proper setting

and, shot several times, quite unintentionally, using 135 grains of 2fg DuPont powder. On the 3rd or 4th shot, the barrel became so fouled with the overcharge of powder that, while attempting to reload, he stuck a patched ball in the barrel, some 18 inches down from the muzzle. Attempting to pull the stick ball and patch combination, he managed to pull the end of his ramrod off, and in a pique, decided to shoot the darn thing out.

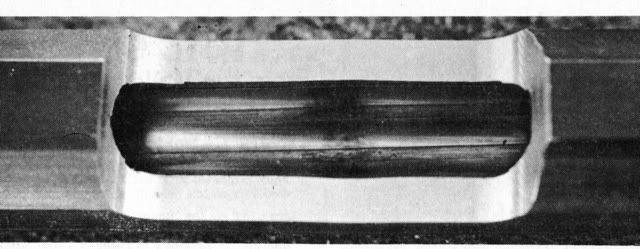

That the barrel did not burst is a tribute to the high quality barrels being produced by G. R. Douglas. It would be difficult to estimate the amount of pressure that was developed in this barrel, as a result of the obstruction formed by the lodged ball and patch, but suffice it to say that it was extremely high. The heat generated had to be terrific - the polished surface of the bore, where the escaping gas went around the stuck ball, turned blue, while the pressure forced an inner ring in the barrel at that point, before the ball and patch ~ combination came loose and was blown out the muzzle. The outside of the barrel suffered no change in shape, nor was the rifle otherwise damaged; something that would not have been the case had the barrel burst. A fine, handcrafted rifle would have been destroyed, had that occurred.

The barrel, 44 inches in length, 7/S" across the flats, had a bore diameter of .450". The ball, patched in oiled linen measuring .012", had a diameter of .440". As reported in a preceding paragraph, the powder charge at the time was 135 grains of 2fg DuPont. The shooter had been shooting muzzleloading firearms since 1948 - an indication that even the most experienced muzzleloading enthusiast can occasionally get into trouble. Had this particular barrel been of lesser quality, in terms of tensile strength, the shooter would have suffered possible physical injury, to say nothing of the grave financial loss due to destruction of his rifle. As it turned out, a new barrel was installed to replace the damaged one and the rifle was returned to a much wiser, very thankful black

powder shooter.

This Douglas barrel withstood tremendous pressure caused by a bore obstruction 18 inches from the muzzle. Cut-away view of barrel shows fire-ring caused by heat and pressure of escaping gas.