What he said.Wow.....

Just wow,,,,,

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Apprentice and Her English Fowler

- Thread starter dave_person

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cruzatte

50 Cal.

It's really a treat to have a student like that. Congratulations to the both of you, Dave & Maria.

Positively inspiring. Passing on the crafts and trades of our founding...a calling of the highest order. Well done to BOTH of you.

Thanks again for doing what you do to share your knowledge and skills with the youth of today. You will be rewarded in due time I'm sure. Thanks again.Hi,

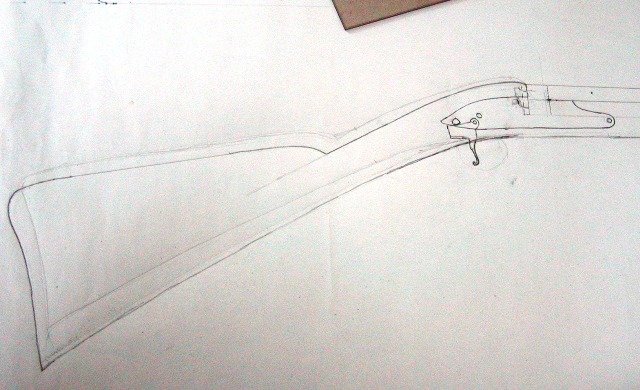

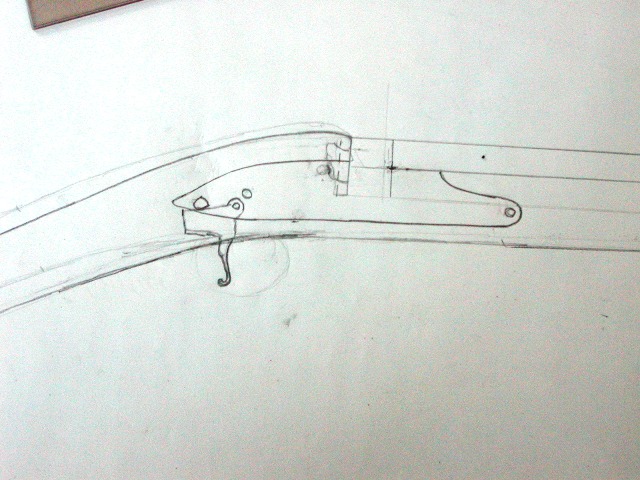

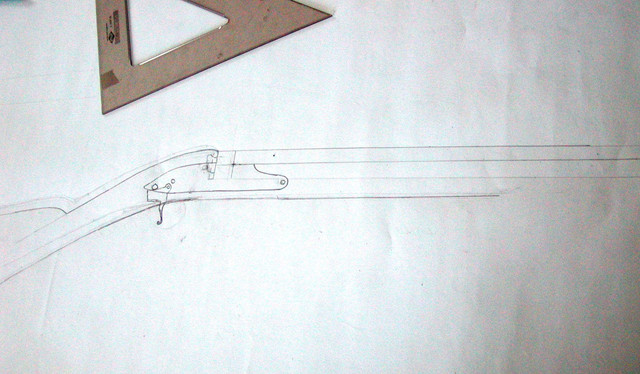

Lots of stuff happening this winter. I have an apprentice, Maria Gray. She is a local high school senior who is greatly focused on history. She is a member of Herrick's Vermont Rangers and Warner's Green Mountain Boys. She intends to major in history in college. Maria is extremely smart and a lightning quick study. She wrote a grant proposal to her school for a senior project making a flintlock gun and learning the history of their manufacture. The school system in Bethel, VT awarded her $1000 for the project. Maria is the second high school student supported by their schools (different school systems) to work with me to build historical guns. I am informed that more are coming. Maria and I dug deeply into the history of arms carried by those units. It was clear that many carried muskets, including the long land pattern Brown Bess but also civilian fowlers. The fowler fit Maria better because she wants to use it for reenacting but also for hunting. She is tall and needs quite a bit of drop in the stock such that the muskets would be horrible guns for her. I showed her a range of examples of fowlers available to 18th century New Englanders and she chose an English export fowler (not a trade gun, which seems to obsess so many who think colonists only carried old muskets, rifles, and trade guns, a terrible distortion of reality). So we are making a good quality English export fowler based on my work and a gun restored by Jim Kibler that I own. The lock will be a Chambers round-faced English lock, the barrel will be a 20 gauge Rice Dolep barrel, the stock is a nice piece of English walnut that I bought from Jim Kibler some years ago. We have not decided on whether the mounts will be brass or iron (steel). I have a Fabulous iron plate forged by Ian Pratt, which is a possibility. This will be fun and I will post updates as we proceed. Here are our preliminary drawings but we have to add more drop. They are tracings of original 1760s fowlers that I own.

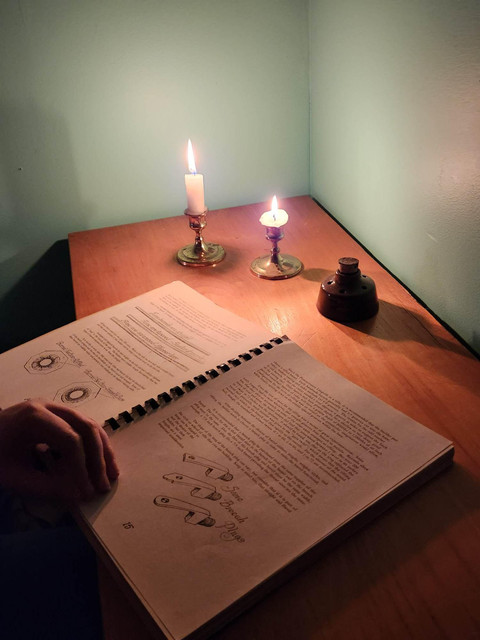

Maria really gets into the 18th century. She has my copies of Grinslade's "Fowlers", John George's "English Guns and Rifles", Dixon's "The Art of Making the Pennsylvania Longrifle" , my working copy of Neal and Back's "Great British Gunmakers 1740-1790", and papers by DeWitt Bailey and Joe Puleo on the Wilson family and Ketland family of gunmakers; respectively. She enjoys reading by candle light. I advised her to freeze the candles first and they will last longer.

dave

[

appalichian hunter

75 Cal.

- Joined

- Oct 28, 2018

- Messages

- 5,828

- Reaction score

- 9,477

Outstanding, pupil and teacher.

- Joined

- Feb 3, 2022

- Messages

- 955

- Reaction score

- 1,423

Fantastic work passing on the torch!

I can't imagine suggesting gun education of any kind to a school in NYS. This young lady is a treasure for our sport, and fortunate to be in an area where the educators see the value in what she is doing.

- Joined

- Mar 23, 2015

- Messages

- 5,023

- Reaction score

- 3,611

Dave, you are doing a wonderful thing passing along a small bit of your knowledge to her.

That is awesome! Reading by candlelight is one of my favorites, while reading the book.

Montgomery

Defender of Truth & Faith, Lord of the Rift

I like the look but not the results. I need alot more light than that to be able to read anything!! : )That is awesome! Reading by candlelight is one of my favorites, while reading the book.

- Joined

- Dec 13, 2004

- Messages

- 109

- Reaction score

- 205

Well done (or at least well begun!), Maria and Dave! Maria, you will end up with a project you will treasure forever. Best wishes for every success.

DuncNZ

54 Cal.

Wow , good on both of you .Also good on the school for letting Maria take your class .That is the way education should be .

Birddog1911

40 Cal

- Joined

- Sep 8, 2021

- Messages

- 434

- Reaction score

- 500

Dave, I truly admire your taking an apprentice. As much as I admire the young lady for becoming one! I can actually say that I'm jealous for the ability to pass on such a wonderful endeavor. I wish you and her the greatest of success.

- Joined

- Nov 26, 2005

- Messages

- 5,245

- Reaction score

- 11,017

Hi Everyone,

Thank you all for looking and supporting Maria. She is an exceptional person and student. She was offered a scholarship at Siena College near Albany, NY that would pay 80% of her tuition and living costs for 4 years to major in history. Because she rides horses, she was one of the Civil War soldiers representing the 2nd Vermont in a parade last weekend. She appreciates your support and good wishes.

We should be getting the barrel any day but in the meantime, we worked on her iron butt plate. It was forged by Ian Pratt but we need to tweak it a little for her project and clean it up. The first step was to widen the return a little by decreasing the domed shape making the top a little flatter. So I taught Maria how to use my Oxy/Acetylene welder. She used it to heat the plate while I hammered it into final shape. Here she is looking very "retro".

Then we gave the plate a little more crescent on the face including adding a little positive pitch. I explained to her how that should help fit the gun better to her build. Then she cleaned it up with files. We have more shaping to do but it is coming along nicely and today was a good lesson in metal work as well as gun architecture. She learns so fast it is scary.

dave

Thank you all for looking and supporting Maria. She is an exceptional person and student. She was offered a scholarship at Siena College near Albany, NY that would pay 80% of her tuition and living costs for 4 years to major in history. Because she rides horses, she was one of the Civil War soldiers representing the 2nd Vermont in a parade last weekend. She appreciates your support and good wishes.

We should be getting the barrel any day but in the meantime, we worked on her iron butt plate. It was forged by Ian Pratt but we need to tweak it a little for her project and clean it up. The first step was to widen the return a little by decreasing the domed shape making the top a little flatter. So I taught Maria how to use my Oxy/Acetylene welder. She used it to heat the plate while I hammered it into final shape. Here she is looking very "retro".

Then we gave the plate a little more crescent on the face including adding a little positive pitch. I explained to her how that should help fit the gun better to her build. Then she cleaned it up with files. We have more shaping to do but it is coming along nicely and today was a good lesson in metal work as well as gun architecture. She learns so fast it is scary.

dave

Always great to see Maria's "Progress Reports"

- Joined

- Nov 26, 2005

- Messages

- 5,245

- Reaction score

- 11,017

Hi and thanks for your support for Maria!

We worked on the butt plate some more today. Here is our inspiration, a 1760s English fowler restored by Jim Kibler.

We are not copying this plate but using it for inspiration. The forged plate by Ian Pratt has the height, crescent face, and overall shape that Maria wants. However, we are tweaking it a bit to make it closer to our model. You might ask why not just use a common commercially made English fowler butt plate? Well, none have much crescent to the face and none are tall enough. That is the reason I use the "Dubbs" longrifle butt plates sold by TOW for many of my 18th century British guns. With some welding or stretching of brass, it can be made into a much more elegant English fowler butt plate than the usual products available. In this case, we had Ian's plate and decided it would work well with some changes. Moreover, the modifications are exceedingly valuable for teaching gun work and basic skills any apprentice or serious muzzleloader gun maker should master.

Maria filed the butt plate to bring it closer to our model.

We welded steel to the plate to make the forward end a bit wider so we could shape it more to our model. Maria cleaning up the welds with the Dremel destroyer. More to come.

dave

We worked on the butt plate some more today. Here is our inspiration, a 1760s English fowler restored by Jim Kibler.

We are not copying this plate but using it for inspiration. The forged plate by Ian Pratt has the height, crescent face, and overall shape that Maria wants. However, we are tweaking it a bit to make it closer to our model. You might ask why not just use a common commercially made English fowler butt plate? Well, none have much crescent to the face and none are tall enough. That is the reason I use the "Dubbs" longrifle butt plates sold by TOW for many of my 18th century British guns. With some welding or stretching of brass, it can be made into a much more elegant English fowler butt plate than the usual products available. In this case, we had Ian's plate and decided it would work well with some changes. Moreover, the modifications are exceedingly valuable for teaching gun work and basic skills any apprentice or serious muzzleloader gun maker should master.

Maria filed the butt plate to bring it closer to our model.

We welded steel to the plate to make the forward end a bit wider so we could shape it more to our model. Maria cleaning up the welds with the Dremel destroyer. More to come.

dave

primo. so good to see there is a future for our hobby and sport.

primo. so good to see there is a future for our hobby and sport.Don't give up hope, women can play fire also....

- Joined

- Oct 6, 2020

- Messages

- 1,667

- Reaction score

- 2,758

Hey Dave, a lot of people would say Dremel tools have no place in gunmaking. I would be interested to know some of the ways you find them useful?

Similar threads

- Replies

- 30

- Views

- 2K

- Replies

- 77

- Views

- 7K

.

.