Hi,

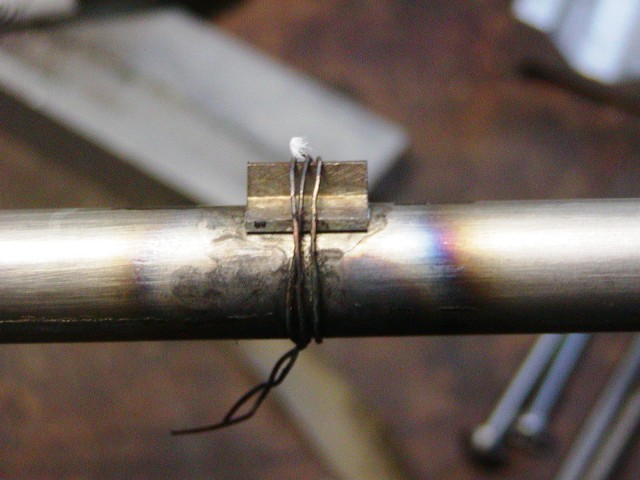

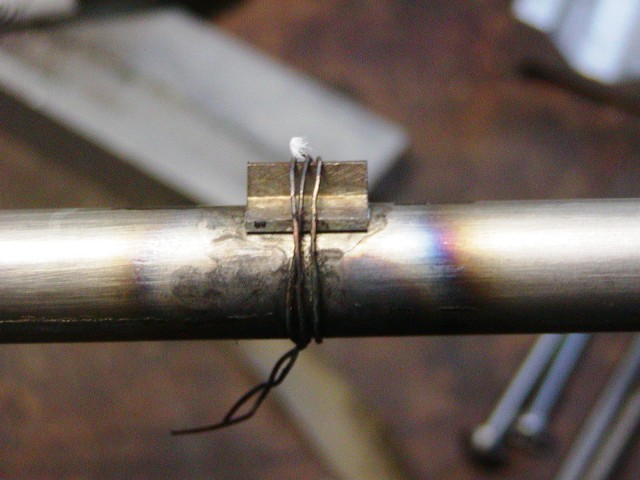

Kind of a grunt work session yesterday. Maria wanted to decompress after her exams this week so she came over to work in the shop. We installed and inlet the barrel lugs. We used milled steel lugs from TOW rather than make them from scratch to save time. I prefer the loops on lugs for barrel keys to be wider providing more metal surface for the key to slide over but these will do fine and are about 3/32" wide. We positioned them to avoid the pipes so they ended up not evenly spaced on the barrel, which is fine. I clean the bottom of the lug and barrel surface thoroughly, then flux the barrel and lug and wire it in place.

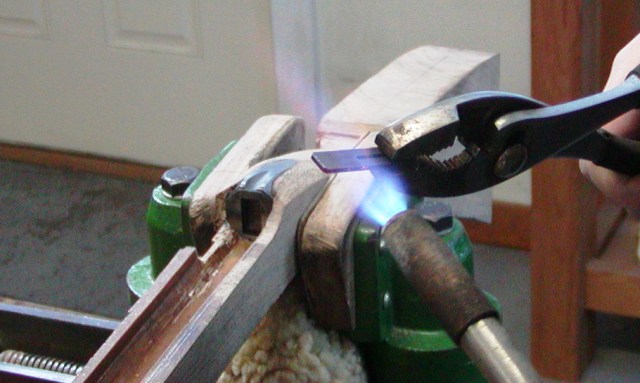

Then we tilt the barrel over on its side and place a little solder (Stay Bright or Hi-Force 44) on top of the the edge along one side of the lug base. Heating from below on the other side of the lug then draws or sweats the solder through the joint. No need to tin the surfaces and try to hold the lug in position as the solder melts on the tinned surface and the lug sits down into the soft solder.

Once soldered in place, Maria ground the edges of the bases down a little to round them.

Next we drill 3 holes in a line to form the slot in the lug. We used a 1/16" drill. After that, we cut out the metal between the holes with a jeweler's saw and file the slot with a flat needle file. We are using cast steel barrel keys that are about 1/16" thick. The slot can and should have a little extra length and width than needed to pass the key. To inlet the lugs in the stock, Maria coated the bottoms of the loops with blacking, she placed the barrel in the stock and squeezed it marking the positions of the loops in the stock. Then she drilled a series of 1/16" holes in the stock and cleared away the wood between holes with a little chisel made from a flat needle file and a bit of fret saw blade held in an X-acto knife handle.

A little filing with a needle file cleans things up and the barrel is placed in the stock with the lug bases blacked. That marks them in the stock and using a 1/4" flat chisel, she cuts nice clean mortises for the bases.

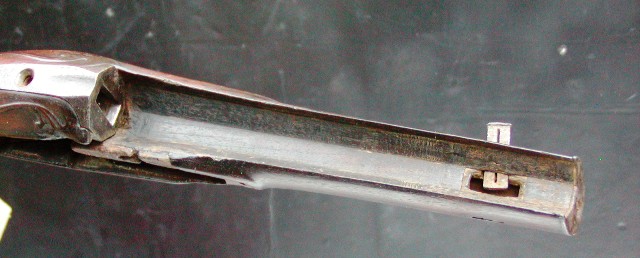

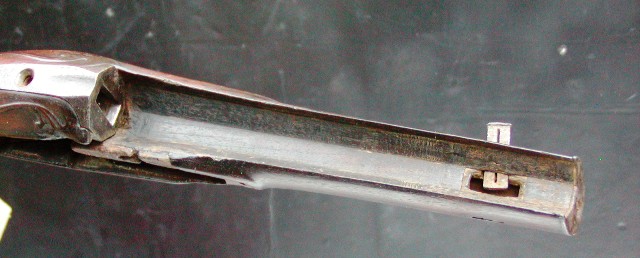

I am not concerned about having the lugs pass through the stock into the ramrod groove and hole. I know some folks obsess about that but when building a correctly slim English fowler from this period, you cannot really avoid having the lugs show in the ramrod groove because the web of wood is thin. You can see how thin the AcraGlas coating is in the barrel channel. You can see the wood grain right through it. It is thin but it really strengthens the side walls of the barrel channel particularly when they may get as thin as this:

On both of those originals, the barrel side walls are very fragile and chipping off in spots.

Next will be installing the barrel keys.

dave

are those her ribbons in thr background or yours

are those her ribbons in thr background or yours