- Joined

- Nov 26, 2005

- Messages

- 5,355

- Reaction score

- 11,628

Hi,

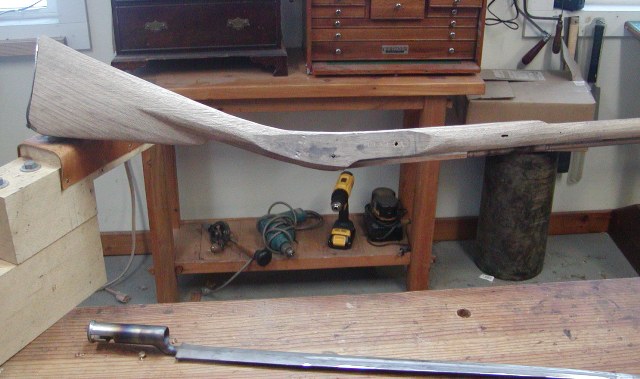

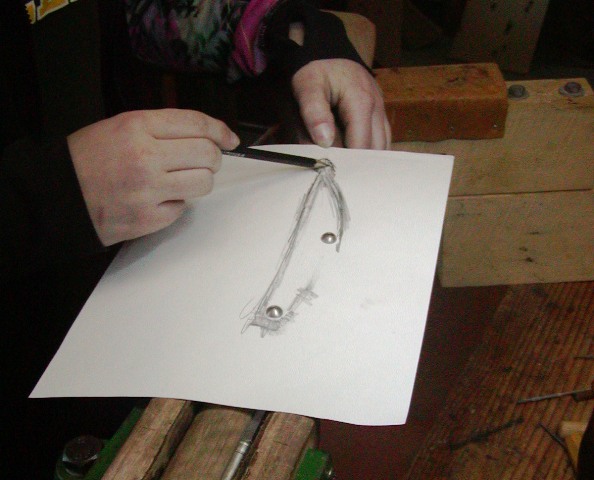

Thank you all for looking and the nice comments about Maria. She is pretty special. We spent most of today preparing her tools and then packing them to ship to Ian Pratt. She should have a good set up for the rifle workshop and a nice nucleus of tools to build on in the future. We did manage to get going on slimming down the fore stock on her fowler. I've described this before but I draw two guidelines on the stock. On this gun one is 1/4" below the top edge of the barrel channel and the other is 5/16" above the edge of the ramrod channel. Using a block plane, Maria cuts even flats using those guidelines such that the fore stock looks a little like the side of an octagon barrel.

She planes to about 1/16" from the barrel on the top facet and leaves about 3/32" for the top of the ramrod channel. Next she rounds the flats using a pattern maker's rasp. In about 20 minutes she has one side down almost to final profile.

Willow came in to inspect the work. She is a tough critic. Eventually, more wood will come off. As Allen Martin says, we will take off wood until scared, and then take off a little more.

dave

Thank you all for looking and the nice comments about Maria. She is pretty special. We spent most of today preparing her tools and then packing them to ship to Ian Pratt. She should have a good set up for the rifle workshop and a nice nucleus of tools to build on in the future. We did manage to get going on slimming down the fore stock on her fowler. I've described this before but I draw two guidelines on the stock. On this gun one is 1/4" below the top edge of the barrel channel and the other is 5/16" above the edge of the ramrod channel. Using a block plane, Maria cuts even flats using those guidelines such that the fore stock looks a little like the side of an octagon barrel.

She planes to about 1/16" from the barrel on the top facet and leaves about 3/32" for the top of the ramrod channel. Next she rounds the flats using a pattern maker's rasp. In about 20 minutes she has one side down almost to final profile.

Willow came in to inspect the work. She is a tough critic. Eventually, more wood will come off. As Allen Martin says, we will take off wood until scared, and then take off a little more.

dave