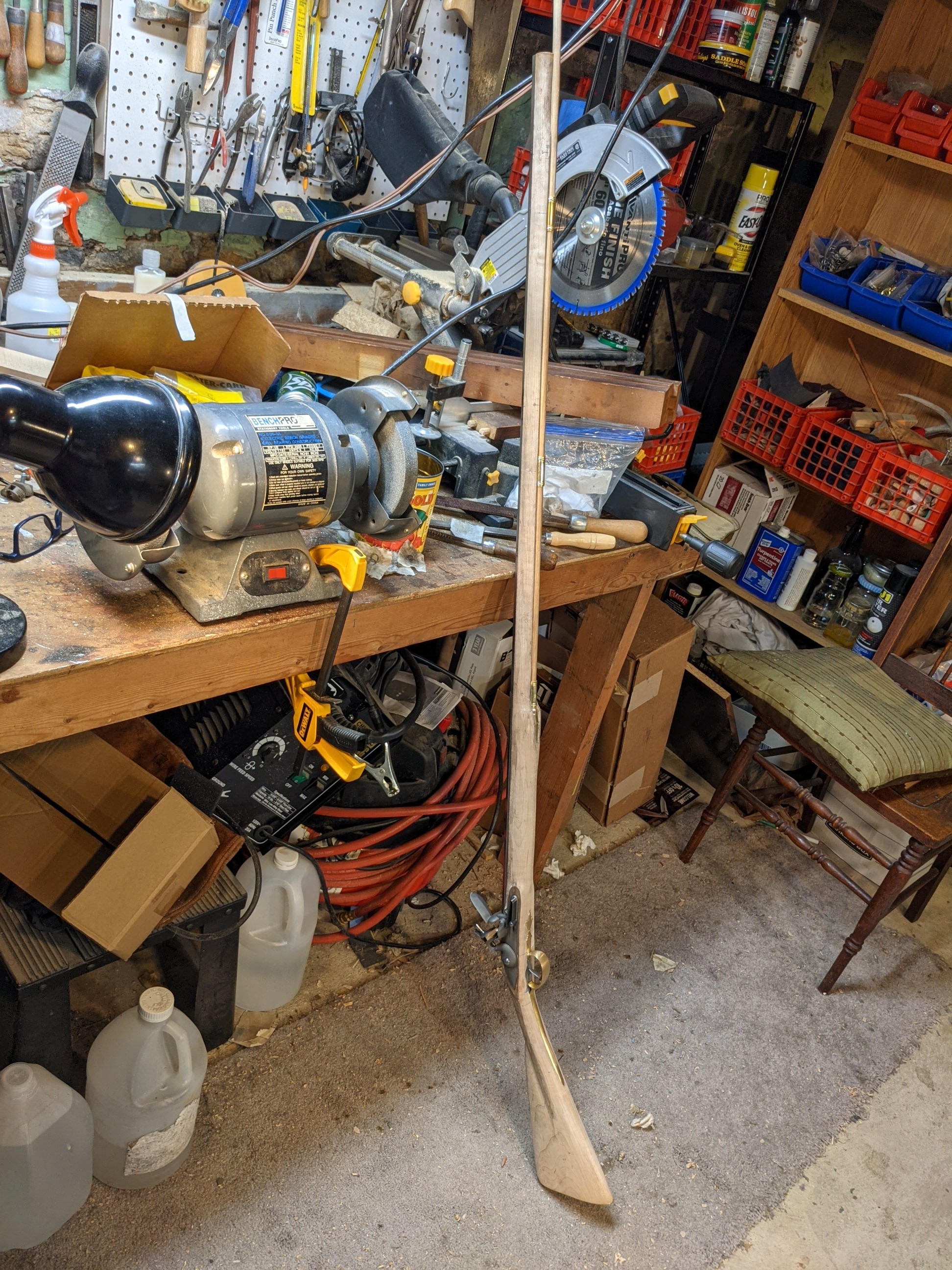

Your fowling piece is looking really good!

Notchy Bob

Notchy Bob

Thanks Notchy Bob!Your fowling piece is looking really good!

Notchy Bob

Yes I did some coldsmithing to shape it to fit the contour and the pre cut inlet which was too big. I used a ball peen hammer to bend it lengthwise and stretch and curve the ears . I spoke with Jim at the CLA show about how to fix the gaps and he said you can pound it out to expand it and file it. If you look at my pictures you can see I had to stretch mine quite a bit. Don't be afraid to shape the metal on any of your hardware if needed.Don't mean to hijack your thread, but I have a question on your trigger plate install. Did you have to bend the plate to get it to fit the contour of the stock? Mine seems to need it or it may mess with the wrist. Also did you bend or file the "ears" to ease into the wrist?View attachment 110756

Glad I could help. I'm following your post. That looks like a nice piece of wood.Thanks, that helps. Yes, that will be needed on mine as well, the ear holes are a bit oversized...

I do have to remove the breech and file the protruding part of the liner first, then it will be a viable firearm!Looks great! You could now throw some powder and shot down the barrel and make smoke!

Thanks! I think a dark finish is appropriate. I'll try some Tannic Acid, Iron Nitrate and finish it with Chambers Gunstock oil. I might add some LMF honey maple stain to the oil or do one coat of the stain on the stock before the oil. I'm definitely going to do a few tests on the inside of the barrel channel before I go for it.Looking good. Have you decided on how you will stain/finish the stock? I'm playing around with the dyes Dave suggested on a piece of scrap

Thanks Buckskin! Yea the constant struggle to keep a clean work area!Looking good! I like the pin holder idea as your bench is clean compared to mine when I get working. I clean it off every week or so, but to no avail...

What is the inside diameter of your ram rod thimbles? Mine are 3/8" and me and Barbie are having a difficult time getting me smaller ones. Sent me pistol thimbles first and then another set of 3/8, ha! I'm tempted to try and make these smaller by cutting out a sliver by the blade and pinching it tight to solder it. Don't know if that would work though.

Enter your email address to join: