- Joined

- Nov 26, 2005

- Messages

- 5,220

- Reaction score

- 10,868

Hi,

What you get from TRS is a pile of cast parts right from the molds. They also have precarved stocks and barrels to go along with the cast parts. Here is an example showing parts for an early pattern Brown Bess musket.

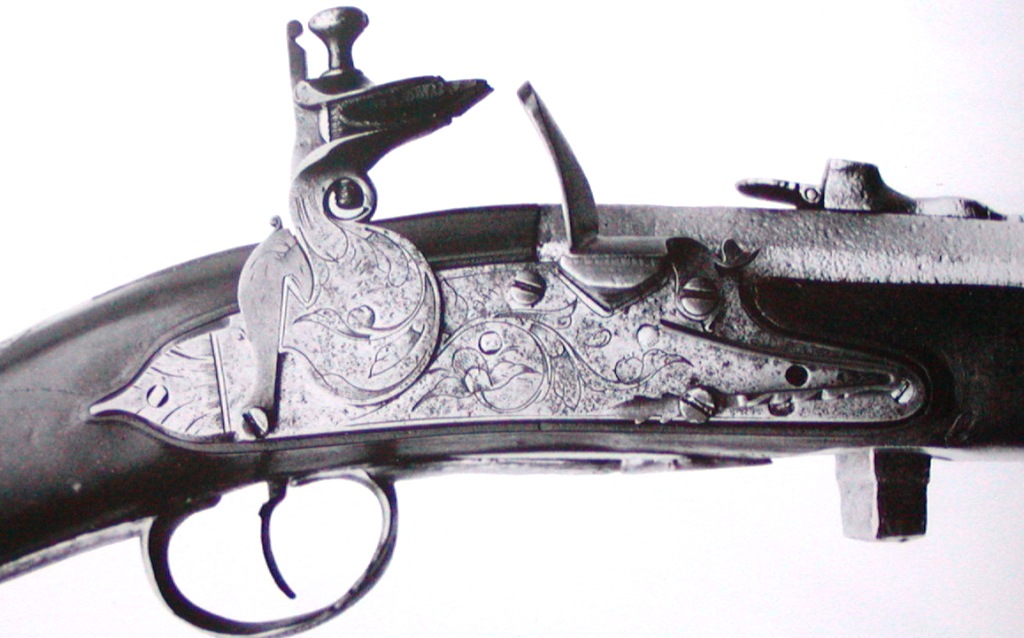

Which then gets made into this:

A musket sized English dog lock is a good first project for this kind of work because it is simple and the parts are large. Usually, that means they have enough extra metal for you to work with. Small pistol locks are not good first projects because they require exact precision of fitting with no room for error. The key for any lock without an internal bridle is a precise fit of the tumbler post in the hole in the lock plate. You have to fit the parts but also heat treat them. Springs, internal parts, frizzen, and often the lock plate and flintcock have to be hardened and then tempered. The Rifle Shoppe (TRS) will assemble locks for you but the wait for those can be very long. If they have your parts in stock, they usually are prompt in sending them out but if they have to wait on a foundry run, it can be months even a year before you get the parts. The best way to order is to call them to see if the parts are in stock. Usually you will speak with Jane Melot but often you need to leave a message or call several times to get someone. They are a small mom and pop business and everybody is doing multiple tasks. The quality of the parts is usually very good but often lock plates have to be flattened because they may have a slight warp from the casting process. You need to be very careful with small parts because sometimes a portion of the part is buried within the casting sprue, which you file or cut away. A welder is also very useful for filling in metal where shrinkage or casting flaws compromise the fit of a part.

I've made a lot of TRS locks and overall am happy with their products. I've always been able to turn their parts sets into fine locks and firearms but it can be a bit of work and it helps to understand all the details concerning what you are making. Because you may wait months for some components, I rarely order anything I need in a hurry. I order for projects I intend to start months even a year in the future.

Here is a link to a paper that may be useful.

https://americansocietyofarmscollec...5-A-Note-on-Flint-locks-and-the-Flintlock.pdf

dave

What you get from TRS is a pile of cast parts right from the molds. They also have precarved stocks and barrels to go along with the cast parts. Here is an example showing parts for an early pattern Brown Bess musket.

Which then gets made into this:

A musket sized English dog lock is a good first project for this kind of work because it is simple and the parts are large. Usually, that means they have enough extra metal for you to work with. Small pistol locks are not good first projects because they require exact precision of fitting with no room for error. The key for any lock without an internal bridle is a precise fit of the tumbler post in the hole in the lock plate. You have to fit the parts but also heat treat them. Springs, internal parts, frizzen, and often the lock plate and flintcock have to be hardened and then tempered. The Rifle Shoppe (TRS) will assemble locks for you but the wait for those can be very long. If they have your parts in stock, they usually are prompt in sending them out but if they have to wait on a foundry run, it can be months even a year before you get the parts. The best way to order is to call them to see if the parts are in stock. Usually you will speak with Jane Melot but often you need to leave a message or call several times to get someone. They are a small mom and pop business and everybody is doing multiple tasks. The quality of the parts is usually very good but often lock plates have to be flattened because they may have a slight warp from the casting process. You need to be very careful with small parts because sometimes a portion of the part is buried within the casting sprue, which you file or cut away. A welder is also very useful for filling in metal where shrinkage or casting flaws compromise the fit of a part.

I've made a lot of TRS locks and overall am happy with their products. I've always been able to turn their parts sets into fine locks and firearms but it can be a bit of work and it helps to understand all the details concerning what you are making. Because you may wait months for some components, I rarely order anything I need in a hurry. I order for projects I intend to start months even a year in the future.

Here is a link to a paper that may be useful.

https://americansocietyofarmscollec...5-A-Note-on-Flint-locks-and-the-Flintlock.pdf

dave

Last edited: