So here is one list of my sources, from my own collection:

Frizzen Steels 12/6/15

Flintlock frizzens were of wrought iron, with the striking face made of steel. The steel face could be applied in two ways. One was to forge weld a piece of steel to the wrought iron frizzen forging. The other, to braze a piece of steel to the frizzen face. Worn frizzens are said to have been repaired by brazing on a new face.

Examining a few guns, my conclusion is that muskets, both English and American, had no braze line showing. I.e., the frizzens were "steeled" by forge welding a steel face to the wrought iron frizzen forging. That welded piece would then be finish filed, the screw hole drilled, and finally heat treated.

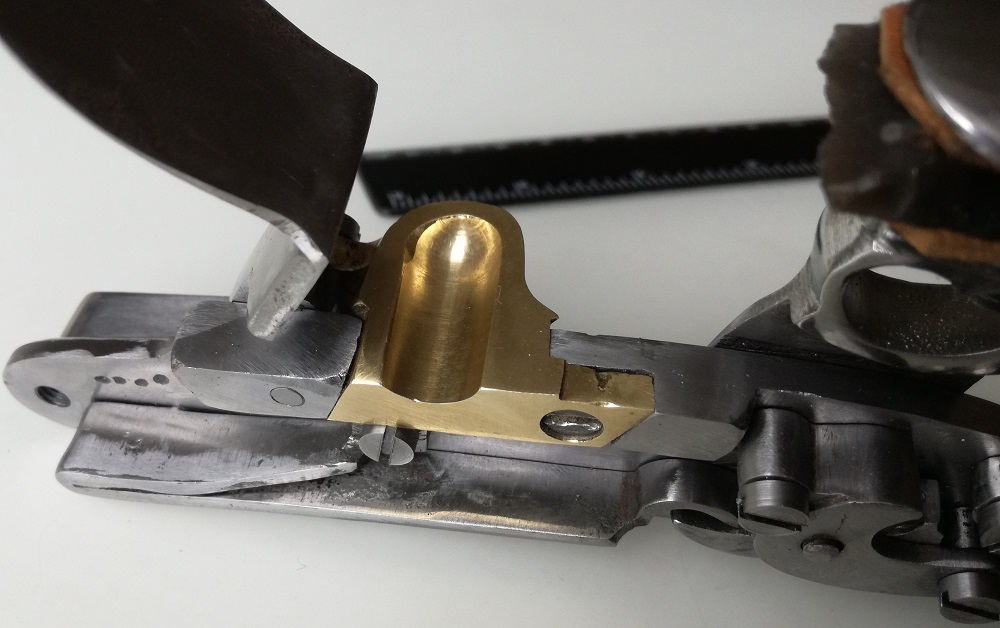

American rifles have the steel, maybe 1/32" thick, brazed to the frizzen.

English pistols - only one shows a braze line. That is a so-called English trade pistol, made with a brass barrel, Birmingham proofs, and single-bridle lock labeled RYAN & WATSON. On this pistol the steel was clearly brazed to the frizzen.

I have only American flint pistol and that a ca. 1760 colonial pistol with English iron parts. It has no braze line visible.

Pistols

American

1. American military, no braze line visible

2. Colonial, American wood & mountings, English lock & barrel. No braze line.

English

1. Wogdon great coat pistols .45 cal, pair. No braze line

2. Early Sea Service pistol, .75 cal. Frizzen worn, no braze line.

3. Light Dragoon, WILLIAMS marked lockplate, .64 cal. No braze line

4. Sea Service, .65 cal, dated 1808. No braze line

5. Richards, iron barrel No braze line

6. I Richards, brass barrel. No braze line.

7. Queen Anne, Blyth. No braze line.

8. Turn-off barrel cal pocket pistol BUNNEY. No braze line

9. RYAN & WATSON brass barrel trade pistol, steel brazed on.

All these English pistols, save one, have frizzens that appear to be welded.

The exception, which does have a braze line, is a so-called English trade pistol, made with a brass barrel, Birmingham proofs, and single-bridle lock labled RYAN & WATSON.

Long guns with welded frizzen faces. All original fint.

1. India pattern Brown Bess, ca. 1810.

2. Paget carbine

3. Irish blunderbuss, single bridle lock marked THOMAS

4. Harpers Ferry 1808 musket dated 181

5. Massachusetts 1808 pattern musket, marked 181

American rifles, all with brazed faces, all locks are original flint

(Brazed frizzen steels tend to be a thin, maybe 1/32" thick, piece of steel.)

1. The one whose frizzen is shown below is listed as Rifle #3, pages 83-84, in

"The Kentucky Rifle", by Capt. John G.W. Dillin, 1924.

BTW, if you do not have Dillin I urge you to get thee a copy and read it.

I read my Dad's in 1951.

It was written a century closer to when muzzle loaders were in daily use.

Modern books on the subject are nice, but they are all, well, -- modern.

"Steel" in the old terminology meant a piece of fairly pure elemental iron which contained anywhere from 1/2% to maybe 1-1/2% carbon. It is the carbon that meant the stuff would get hard when heated red hot then cooled quickly, as by quenching in water.

I am a metallurgist by schooling and quite a few decades.

![Copy of dillinclose0293[600x400][1].jpg](https://cdn2.imagearchive.com/muzzleloadingforum/data/attachments/42/42616-2f0fd9b9b049732974382c57df56bfae.jpg)