Pete G

76 Cal.

Restoration is totally different than trying to make an indifferently assembled pile of scrap metal function as a lock.

Hi,

Kasenite and Cherry red are compounds that are good for very superficial hardening. However, case hardening to a depth necessary for a long lasting frizzen requires time at proper temperature. For deep hardening times need to be in hours.

dave

I had luck on one of those locks with wrap it in leather put it in a soup can .Then put it in a hot hard wood (beech or white oak) 2 hours or so . Make sure to keep it down in the hot center of coals. Pull it out and drop it in a bucket of cold water. When cool re install the frozen and voulla. A sparking frozen. Oh yeah bend the top of the soup can over and crunch it shut with big channel locks. Good luck it works.Dave is EXACTLY right. Kasenite will only work for a limited number of times before the flint scratches/carves its way through the thin surface hardening.

Now if like most of us Audrey22 doesn't have a heat treating oven, then an absolutely authentic period "fix" would be to rivet or better still solder a "half sole," made of real steel, to the face of the Frizzen. If you know anyone who has a power hacksaw, those blades make an excellent source of steel for half soling a Frizzen.

Gus

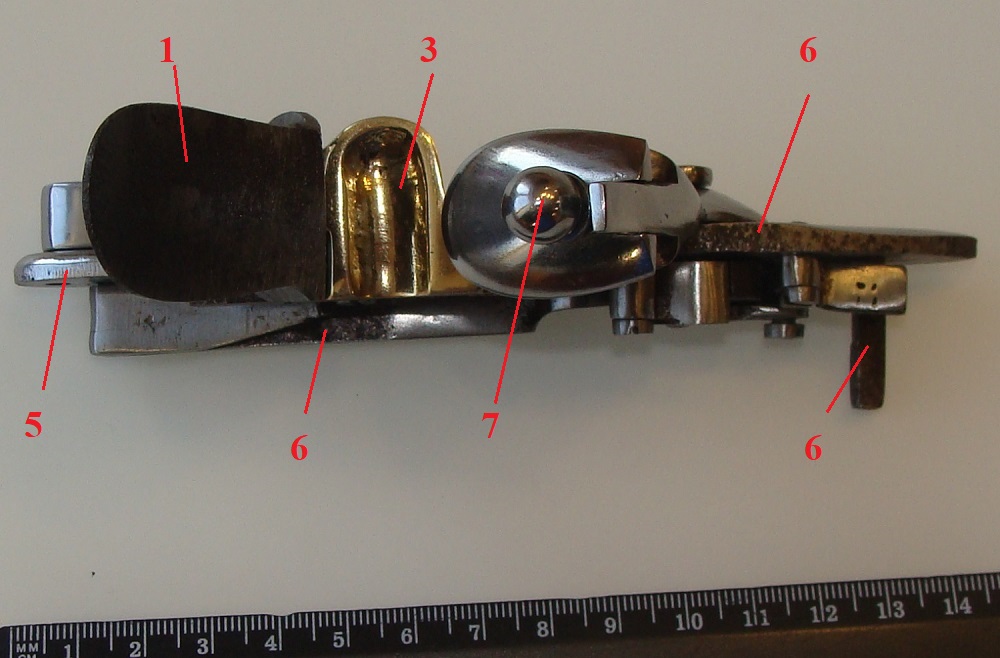

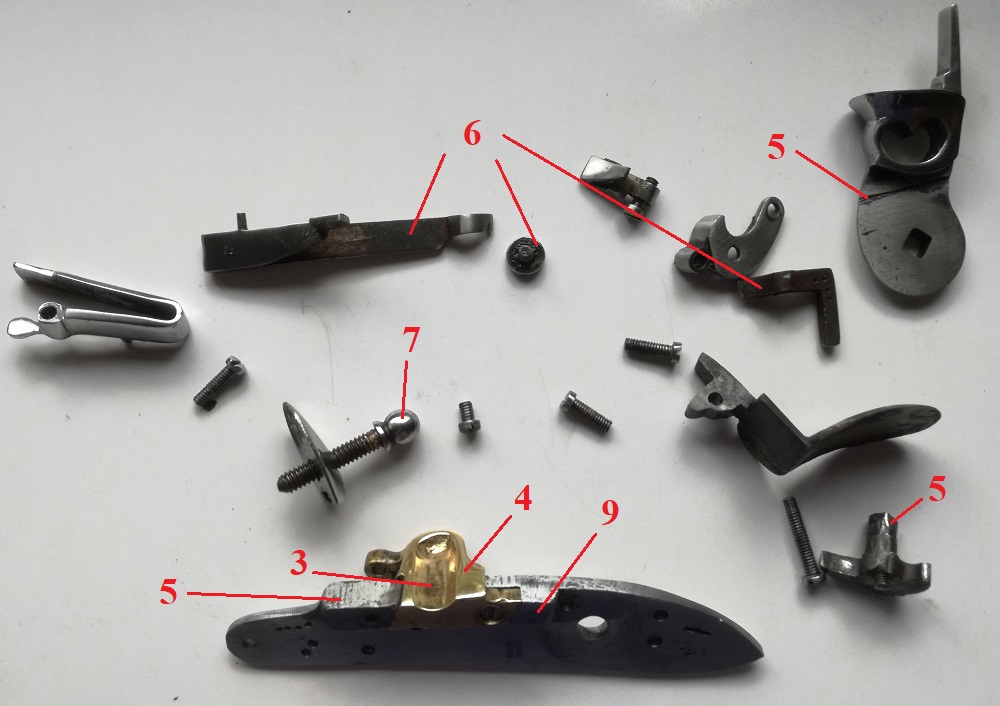

It's almost like some formen at the Indian gun factory said to a worker, "Baboo, we're making nice wall hangers! If you make it any better those silly americans will try to fire them!"This flintlock not throwing sparks. I took apart the flintlock and examined it carefully. The following faults and shortcomings were identified

1. The frizzen does not produce sparks - the steel is of poor quality, there is little carbon in it.

2. The safety descent protrudes too far forward and when the trigger is released from the combat platoon, the sear rests against the safety platoon - it is impossible to descend from the combat platoon.

3. The pan is not even.

4. Large gap between frizzen and pan.

5. Traces of files on the surface of the lock

6. Corrosion on some parts of the castle.

7. The top jaw screw has an irregular shape, the screw has no slots for the screwdriver and hole.

8. The screws are not made correctly and roughly.

9. There is no second threaded hole for the screw fastening the lock to the stock.

Oh I forgot keep your face out of the water bucket.And don't drink the water.Some of us do these things and others just postulate on them.Throw what's left of the can into the water making sure the moon is behind you. And you will survive.I would think the enclosed tin route would bring about a violent explosion of steam .Even sudden plunging into cold water need s be done length ways lest it warp the lock plate . But the cooking in bone horn leather ect charred is sound.

Rudyard

That is one of the compounds in Kasenit. Let me repeat, there are no short cuts to correctly and deeply case hardening a frizzen. The stuff your friend used, unless he packed the frizzen in it and heated for several hours will only have a very shallow hard surface. Unless the actual steel in the frizzen is medium to high carbon so it through hardened in your hardening process, the skin of hardened steel provided by the cyanoferrate will only last a short time.

I had luck on one of those locks with wrap it in leather put it in a soup can .Then put it in a hot hard wood (beech or white oak) 2 hours or so . Make sure to keep it down in the hot center of coals. Pull it out and drop it in a bucket of cold water. When cool re install the frozen and voulla. A sparking frozen. Oh yeah bend the top of the soup can over and crunch it shut with big channel locks. Good luck it works.

Just the frizzen vet's cooked.I would think the enclosed tin route would bring about a violent explosion of steam .Even sudden plunging into cold water need s be done length ways lest it warp the lock plate . But the cooking in bone horn leather ect charred is sound.

Rudyard

I had luck on one of those locks with wrap it in leather put it in a soup can .Then put it in a hot hard wood (beech or white oak) 2 hours or so . Make sure to keep it down in the hot center of coals. Pull it out and drop it in a bucket of cold water. When cool re install the frozen and voulla. A sparking frozen. Oh yeah bend the top of the soup can over and crunch it shut with big channel locks. Good luck it works.

Enter your email address to join: