Well, i've embarked on another project. The Traditions Kentucky Pistol, I bought it from http://www.oldsouthfirearms.com/ and it had pretty fast shipping along with great prices.

I don't know if I'm stupid or not, but I could've just paid extra $25 for the fully assembled and functioning one. Instead I'll likely spend countless hours of sanding, staining and frustration building this little thing. I was originally going to go with the pirate pistol, but, at twice the price and my large credit card bill, I opted for the cheaper one. I got what I paid for. Here are some pictures.

Does anyone know how I can get rid of that writing on the barrel?

Rough carving job by the people who made this

More examples. I'm pretty sure that wood is caved in where the bolt is supposed to go (towards the bottom of the picture). But I think the Bolt should go deep enough to not be a problem

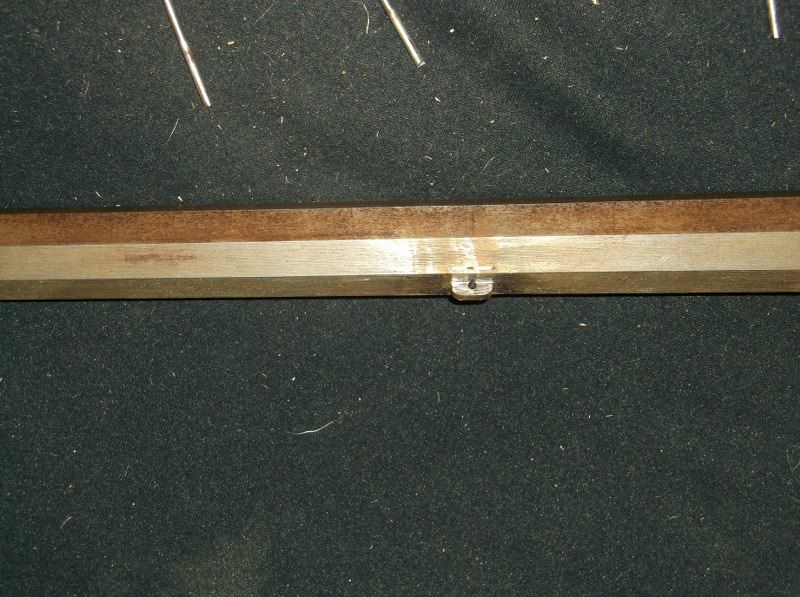

Long view, but you can again see where they left wood shavings.

I did a rough fit, everything except for the trigger guard and the thing for there barrel screwing in fits. The trigger guard is going to take some serious wood removal, but the barrel inlet? tongue? Whatever the end piece that screws into the stock is going to be slight removal.

So, I found the only real difference between the kentucky and pirate pistol is the shape of the handguard (which the kentucky can be shaped down) the bottom brass cap, and of course the flintlock top. Would I be able to find a brass cap from anywhere (like a hardware store) and the flintlock mechanism to swap out on my kentucky pistol?

Trying to eventually get 2 pirate pistols and then put them into a "dueling box" as for decor like see below. I am debating makign the box myself or just paying someone to make it. I assume it would cost ~$150ish to have someone make it. While I could it for $50 + countless hours of frustration.

Thoughts? I'll be updating this with more photos as I do stains and clean things up. Just thought I should start a thread with pictures, as this site seriously lacks them!

I don't know if I'm stupid or not, but I could've just paid extra $25 for the fully assembled and functioning one. Instead I'll likely spend countless hours of sanding, staining and frustration building this little thing. I was originally going to go with the pirate pistol, but, at twice the price and my large credit card bill, I opted for the cheaper one. I got what I paid for. Here are some pictures.

Does anyone know how I can get rid of that writing on the barrel?

Rough carving job by the people who made this

More examples. I'm pretty sure that wood is caved in where the bolt is supposed to go (towards the bottom of the picture). But I think the Bolt should go deep enough to not be a problem

Long view, but you can again see where they left wood shavings.

I did a rough fit, everything except for the trigger guard and the thing for there barrel screwing in fits. The trigger guard is going to take some serious wood removal, but the barrel inlet? tongue? Whatever the end piece that screws into the stock is going to be slight removal.

So, I found the only real difference between the kentucky and pirate pistol is the shape of the handguard (which the kentucky can be shaped down) the bottom brass cap, and of course the flintlock top. Would I be able to find a brass cap from anywhere (like a hardware store) and the flintlock mechanism to swap out on my kentucky pistol?

Trying to eventually get 2 pirate pistols and then put them into a "dueling box" as for decor like see below. I am debating makign the box myself or just paying someone to make it. I assume it would cost ~$150ish to have someone make it. While I could it for $50 + countless hours of frustration.

Thoughts? I'll be updating this with more photos as I do stains and clean things up. Just thought I should start a thread with pictures, as this site seriously lacks them!

Last edited by a moderator: