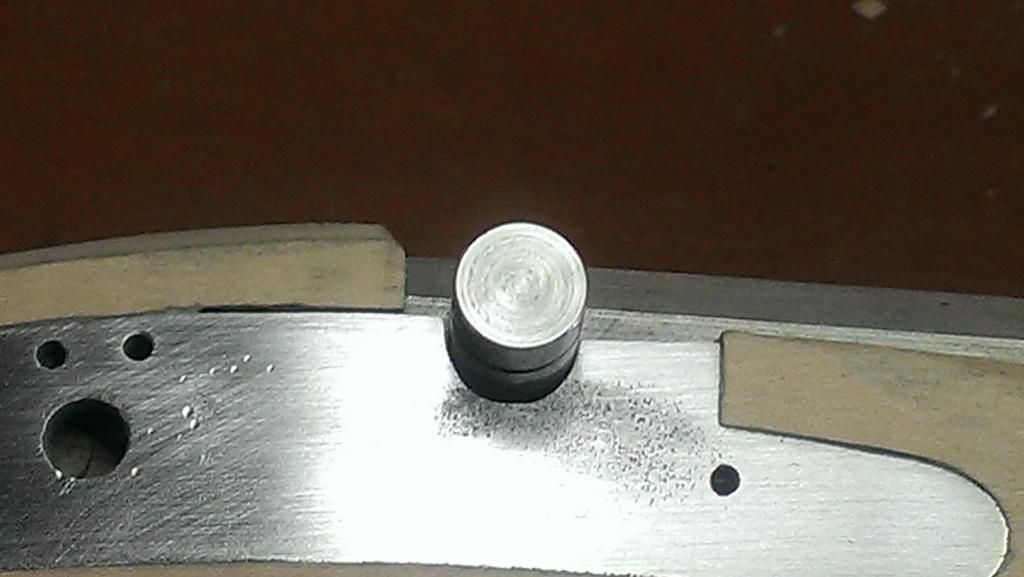

I almost never install dovetails to hold the barrel - prefer staples - and if they are not possible (thin waists on swamped barrels) I solder them on.

Having said that, the "general wisdom" states that you should leave a minimum .050" wall thickness between the bore and your dovetail (whether for a sight or under-lug).

I feel a little better with .080" if I can manage that.

So, just do the math.

For example I did a 7/8" ATF, straight 50 cal barrel recently - it has .012" square rifling.

So the barrel overall is (7/8") = .875"

= .875 - .500 (bore) - .012" - .012 (the rifling on both sides of the bore) = .351" remaining (on both sides of the bore combined) -

So, .351/2 = .1755" of "wall thickness" beyond the extreme of the rifling.

By the "minimum" you could go .1255" deep or by my standard .0955" deep with a dovetail and have "lots of meat" left.

A "standard" dovetail is about .0625" deep (or there abouts) and a staple hole is about .0725".

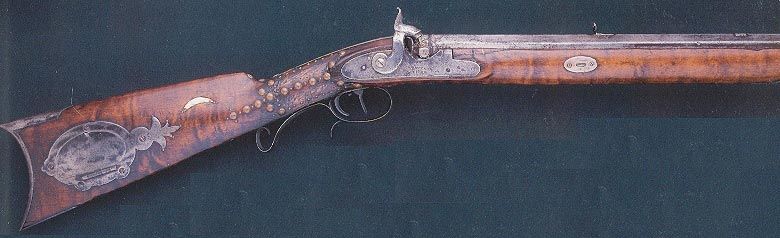

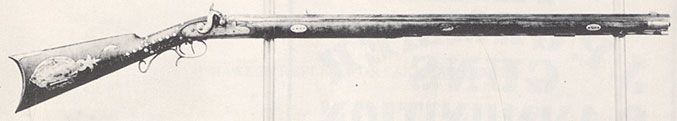

(if you are going for "some" HC, staples would be more correct on a Hawken than a dovetailed lug)

So in the example above unless you are going super crazy with the depth, you would be more than fine.

So my (golden rule) is, if there will be less than .080" wall left, I solder a lug - just to be safe.

(although, if it was at the muzzle end I may be inclined to go down to the .050" minimum - it's most important to keep a safe wall thickness at the breech and it diminishes somewhat the further you get down the barrel towards the muzzle).

p.s. I saw you posted over at ALR and that Taylor responded. Taylor is pretty "up there" in terms of modern builders of Hawken rifles - use his advice and don't be afraid to ask. Don Stith also is a (somewhat) regular contributor and occasionally Louie Parker, who just may be the best contemporary Hawken builder at present.

My own interest in the Hawken brothers is simply incidental to studying their father whom is my favorite rifle builder - they just kinda hog the limelight