Black Jaque Janaviac

40 Cal.

- Joined

- Sep 2, 2009

- Messages

- 535

- Reaction score

- 73

I suppose, there probably ain't much risk in trying it without consulting you folks but. . .

As I look back it has been a long time since I ever needed to pull anything from a barrel while in the hunting field. Whenever I clean I am usually at camp or home where I have access to threaded metal rods. If I dryball, I just work a little powder into the vent.

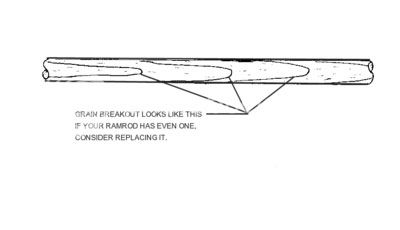

So I broke another ramrod. I am thinking of sayin' heck with the little brass end and just cutting a plain dowel to size.

It seems too simple. I wonder why I haven't heard of other folks doing this.

As I look back it has been a long time since I ever needed to pull anything from a barrel while in the hunting field. Whenever I clean I am usually at camp or home where I have access to threaded metal rods. If I dryball, I just work a little powder into the vent.

So I broke another ramrod. I am thinking of sayin' heck with the little brass end and just cutting a plain dowel to size.

It seems too simple. I wonder why I haven't heard of other folks doing this.