-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Breech plug removal

- Thread starter 9945

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Stophel

75 Cal.

- Joined

- Jul 8, 2005

- Messages

- 5,963

- Reaction score

- 868

Well, I don't have a video, but it's not that complicated. Put the barrel in a leather padded vise, right at the breech (you may want to build up leather padding to compensate for taper in the barrel), and with a suitable wrench (grabbing it from the bottom of the breechplug, NOT the top), just turn the breechplug out. Sometimes just an ordinary crescent wrench will work fine. Some people use a pipe wrench with the teeth ground off the jaws. Some people have a purpose-made wrench with a tapered slot to fit tapered breechplugs.

For a book on general flintlock gunsmithing, the old book "The Art of Building the Pennsylvania Longrifle" by Chuck Dixon is as good as any, and better than some. :wink:

For a book on general flintlock gunsmithing, the old book "The Art of Building the Pennsylvania Longrifle" by Chuck Dixon is as good as any, and better than some. :wink:

- Joined

- Aug 27, 2004

- Messages

- 3,146

- Reaction score

- 6,932

Sorry, can't help with videos,

Make sure the barrel is unloaded (that is a given). Clamp in a good vice, close to the breech plug, but not on it. Don't want to be squeezing what you are removing. Make sure if there is a vent liner it is not encroaching on the breech plug threads. Stamp or engrave a reference mark on the underside of the breech plug for reinstallation. You need a wrench that fits the breech plug taper, and then a cheater pipe for leverage. Go slow and easy, with a 2 to 3 foot cheater it should come out.

Flintlocklar :wink:

Make sure the barrel is unloaded (that is a given). Clamp in a good vice, close to the breech plug, but not on it. Don't want to be squeezing what you are removing. Make sure if there is a vent liner it is not encroaching on the breech plug threads. Stamp or engrave a reference mark on the underside of the breech plug for reinstallation. You need a wrench that fits the breech plug taper, and then a cheater pipe for leverage. Go slow and easy, with a 2 to 3 foot cheater it should come out.

Flintlocklar :wink:

IT may be a pertinent question as to why you need it out?

They should not be removed as a matter of course, only for bore work such as fine-boring, re-rifling etc.

The breechplug is an interruption fit and if at all possible, should be left alone.

All the best,

Pukka.

They should not be removed as a matter of course, only for bore work such as fine-boring, re-rifling etc.

The breechplug is an interruption fit and if at all possible, should be left alone.

All the best,

Pukka.

- Joined

- Jan 31, 2016

- Messages

- 1,296

- Reaction score

- 2

Like RJDH mentioned, there's not any scenario that I can think of where you would want to remove a properly seated breech plug. Any bore work needs to be sent to a professional.

Also, what do you mean by "typical" as far as muzzleloaders go? If you mean a factory muzzleloader, as that is what we typically see, it is my understanding that the breech plugs are permanently installed by the factory and any nonprofessional attempting to remove them will cause damage?

On a barrel where it is safe to remove the breech plug, It's useful to bend a small strip of brass and place that between the plug and wrench to prevent any marring. I think this was already mentioned, but definitely scribe a small line on the bottom flat of the barrel and breech plug before doing anything so that you know where to return it to a seated position.

Also, what do you mean by "typical" as far as muzzleloaders go? If you mean a factory muzzleloader, as that is what we typically see, it is my understanding that the breech plugs are permanently installed by the factory and any nonprofessional attempting to remove them will cause damage?

On a barrel where it is safe to remove the breech plug, It's useful to bend a small strip of brass and place that between the plug and wrench to prevent any marring. I think this was already mentioned, but definitely scribe a small line on the bottom flat of the barrel and breech plug before doing anything so that you know where to return it to a seated position.

I don't need it out....I just want to learn how to do it properly....that's the way I am....I have a wanderlust for knowledge......worked in tool and die for yrs and I like to know how things are put together and come apart....I need to learn the "why" they should be left alone and what to do IF they need to come apart!!

Larry Akers

40 Cal.

- Joined

- Jun 6, 2016

- Messages

- 418

- Reaction score

- 205

I have a 5" bench vice and I clamp a barrel horizontally between brass or lead pads to install breechplugs. I do it horizontally because it gives me 5" of barrel surface to grip as opposed to the 1/2" or less a vertical clamp will give. The barrel is less likely to rotate and ruin the corners. Plug removal is the same if ever needed.

Clamp in a good vice, close to the breech plug, but not on it. Don't want to be squeezing what you are removing.

Yeppers.

Worth repeating:

Clamp in a good vice, close to the breech plug, but not on it. Don't want to be squeezing what you are removing.

Last time I pulled one was about 1983, there are very few reasons I can think of to pull one.

We really need a sticky on this.

If the plug is loose you can get by with a bench vice an a cresent wrench. IF it is tight you will make a big mess in a hurry. You'll find out when you try.

For a tight plug a bench vice will not do. You will need a real barrel vice. Maple blocks that are closely fitted to the barrel work well. So does aluminum and steel. Put some rosin on them. For octagonal barrels I use steel V-blocks with business card liners. My barrel vice is a large hydraulic unit. For wrenches I use opposing jaw steel units with fine thread bolts to draw them up tight.

Really tight plugs, Like TC's require a properly fitted wrench and a real barrel vice.

Once the plug is out it can be fitted to a reasonable torque. After that the bench vice and cresent wrench will work OK.

Unless you have a compelling reason leave the plug alone.

If the plug is loose you can get by with a bench vice an a cresent wrench. IF it is tight you will make a big mess in a hurry. You'll find out when you try.

For a tight plug a bench vice will not do. You will need a real barrel vice. Maple blocks that are closely fitted to the barrel work well. So does aluminum and steel. Put some rosin on them. For octagonal barrels I use steel V-blocks with business card liners. My barrel vice is a large hydraulic unit. For wrenches I use opposing jaw steel units with fine thread bolts to draw them up tight.

Really tight plugs, Like TC's require a properly fitted wrench and a real barrel vice.

Once the plug is out it can be fitted to a reasonable torque. After that the bench vice and cresent wrench will work OK.

Unless you have a compelling reason leave the plug alone.

Thanks for the info....I'll try Brownells for the barrel vise and steel jaws.....I know one should leave this alone unless you "MUST" remove one....to satisfy my lust for knowledge...I'll have to do it at least once.....I have a few parts guns (antiques) that I'll give it a go with!!

Don't want to ruin even a parts gun...just want to learn how to do this in the best manner possible....won't try anything till I'm satisfied that I have the right amount of info to get strted.

Thanks for your time and info!!

Don't want to ruin even a parts gun...just want to learn how to do this in the best manner possible....won't try anything till I'm satisfied that I have the right amount of info to get strted.

Thanks for your time and info!!

Don't try to remove the breech plug on a CVA or Traditions rifle. The drum or touch hole are threaded into the breech plug.

Like the others said, it's best to leave things alone when it comes to removing the breech plug.

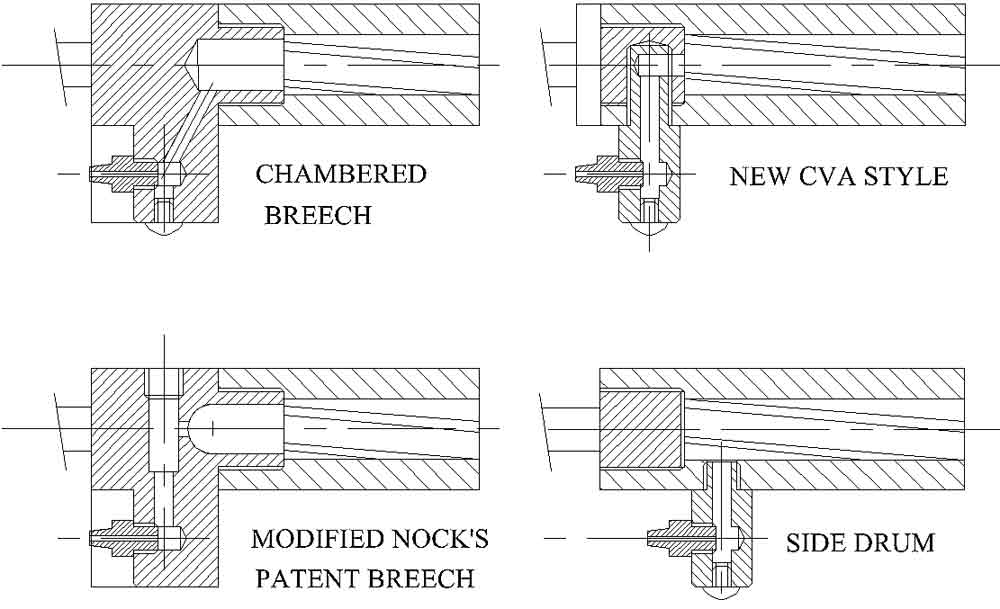

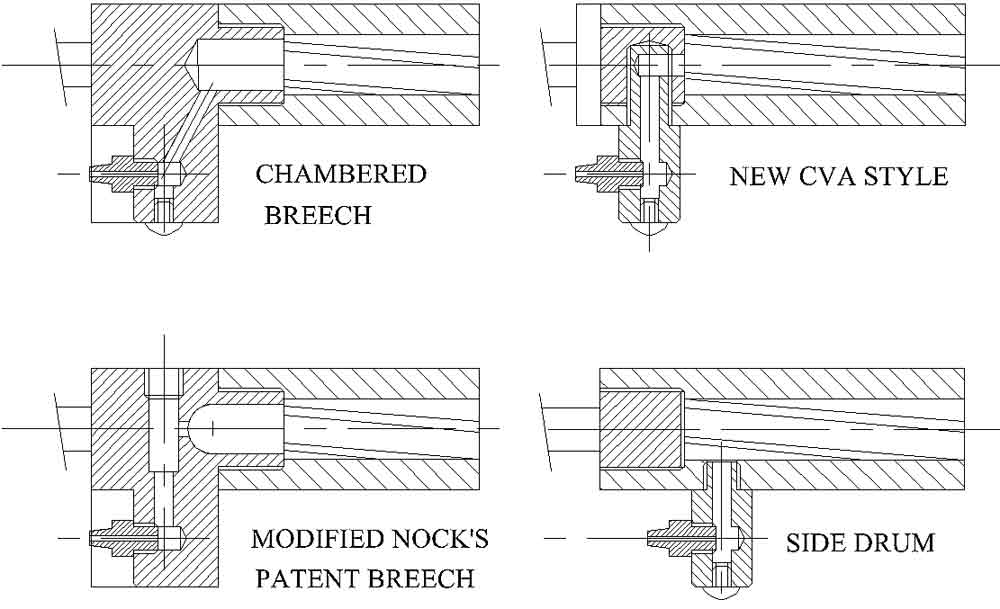

In the drawing below, notice that most breech plugs are just screwed into the rear of the barrel until they shoulder out against the flat face at the rear of the bore and make contact with the face at the rear of the barrel.

Yes, they make contact at two different places at the same time. That's why there is more to fitting a breech plug than just screwing it in until it stops on something.

In the case of the CVA and Traditions guns, either a threaded part with the vent installed or a drum holding the nipple is screwed into a threaded hole thru the side of the breech plugs threads.

This locks the plug in place making the removal of the drum or vent mandatory before attempting to actually unscrew the breech plug.

In the drawing below, notice that most breech plugs are just screwed into the rear of the barrel until they shoulder out against the flat face at the rear of the bore and make contact with the face at the rear of the barrel.

Yes, they make contact at two different places at the same time. That's why there is more to fitting a breech plug than just screwing it in until it stops on something.

In the case of the CVA and Traditions guns, either a threaded part with the vent installed or a drum holding the nipple is screwed into a threaded hole thru the side of the breech plugs threads.

This locks the plug in place making the removal of the drum or vent mandatory before attempting to actually unscrew the breech plug.

During the building of mainly flintlock LRs and a few Hawken style rifles, I've unscrewed breechplugs many times and there's nothing mysterious or difficult about doing it.

I use a bench vise w/ copper jaw inserts, a Crescent wrench, copper shims to put on both sides of the breechplug bolster, a 2 foot length of pipe that fits over the handle of the Crescent wrenh and a chisel to mark the bbl and breechplug position.....if not already done.

Clamp the bbl tightly near the breech end but not on the threaded portion, put the copper shims between the wrench jaws and bolster and slip on the "cheater pipe" and unscrew the breechplug.The bbl is clamped in the vise horizontally.

Reinstalling the breechplug is slightly more difficult than unscrewing it....half the chisel marks on both the bbl and bolster have to be aligned and before starting, the threads are sparingly lubed w/ a good grease.. The same setup is used as for removal and the "cheater pipe" hakes it a lot easier to align the chisel marks.....I use a magnifier when doing this. A few attempts will probably be made to align the chisel marks.

The upper part of the breechplug that contacts the top flat of the bbl shouldn't have oil or grease on it if either bluing or browning is to be done.....the "seam" area won't take a finish......Fred

I use a bench vise w/ copper jaw inserts, a Crescent wrench, copper shims to put on both sides of the breechplug bolster, a 2 foot length of pipe that fits over the handle of the Crescent wrenh and a chisel to mark the bbl and breechplug position.....if not already done.

Clamp the bbl tightly near the breech end but not on the threaded portion, put the copper shims between the wrench jaws and bolster and slip on the "cheater pipe" and unscrew the breechplug.The bbl is clamped in the vise horizontally.

Reinstalling the breechplug is slightly more difficult than unscrewing it....half the chisel marks on both the bbl and bolster have to be aligned and before starting, the threads are sparingly lubed w/ a good grease.. The same setup is used as for removal and the "cheater pipe" hakes it a lot easier to align the chisel marks.....I use a magnifier when doing this. A few attempts will probably be made to align the chisel marks.

The upper part of the breechplug that contacts the top flat of the bbl shouldn't have oil or grease on it if either bluing or browning is to be done.....the "seam" area won't take a finish......Fred

I bought one of the Rice barrel vise jaws and one the breech plug wrenches, well designed and makes pulling the plug easy.

Going a bit further, If you Do have a breechplug out, I found when I had an old barrel de-breeched that the threads had been covered in Stockholm tar.

This barrel had been hammered breech -first into the ground to help fill a hole in a hedge (!!)

It was a percussion rifle barrel. (Back in Yorkshire , this)

I wondered if I could do anything with the bore so decided to de-breech it.

I warmed it up pretty well, as it was terribly rusted, and tar started to sizzle out of the breech threads.

After warming, the breech unscrewed no bother , and the threads were like new! still shiny.

The bore was far too pitted to do much with it, as it had had maybe 100 years of water down the bore, but that tar, (like pine tar) had saved the threads from any water damage.

After this, I always use pine tar on the threads if I Do have to de-breech.

Richard.

This barrel had been hammered breech -first into the ground to help fill a hole in a hedge (!!)

It was a percussion rifle barrel. (Back in Yorkshire , this)

I wondered if I could do anything with the bore so decided to de-breech it.

I warmed it up pretty well, as it was terribly rusted, and tar started to sizzle out of the breech threads.

After warming, the breech unscrewed no bother , and the threads were like new! still shiny.

The bore was far too pitted to do much with it, as it had had maybe 100 years of water down the bore, but that tar, (like pine tar) had saved the threads from any water damage.

After this, I always use pine tar on the threads if I Do have to de-breech.

Richard.

I think any agricultural co-op will have it in the horse /animal section.

It's used to treat wounds and such. Comes in maybe a half pint tin.

Best warm the threads before re-assembly so the pine tar will run and spread nicely.

Vets will have it as well.

All best,

Richard.

It's used to treat wounds and such. Comes in maybe a half pint tin.

Best warm the threads before re-assembly so the pine tar will run and spread nicely.

Vets will have it as well.

All best,

Richard.

Really tight plugs, Like TC's require a properly fitted wrench and a real barrel vice.

TC used to sell a special 'wrench' that fit over the patent breech for plug removal. I bought mine in the early 1970s. It has never been used.

Similar threads

- Replies

- 5

- Views

- 419

- Replies

- 4

- Views

- 273

- Replies

- 66

- Views

- 4K

- Replies

- 50

- Views

- 4K

Latest posts

-

-

-

Does anyone make/sell something like a snap cap cone to dry fire a revolver?

- Latest: Colonial Boy

-

-

-

-

-

-

-