Monkeyman

36 Cl.

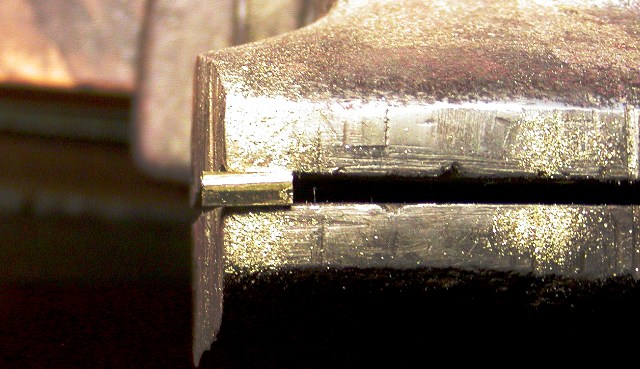

Also, I have another question. How in the world did they mount these brass front sights? I can't see any evidence of solder of dovetailing. The plan is to get a small block of brass and file it do get the shape of a front sight, but I have no ides how they mounted them.