torontoalex

32 Cal.

- Joined

- Nov 28, 2013

- Messages

- 9

- Reaction score

- 0

Hi folks,

I have had a consistent problem ever since I inherited my father's Hawkin replica.

I think I caused the problem. When I first took the gun out, I shot 10 shots in a row, without cleaning between shots. On the next shot, something (bad) happened and the hammer was shot backwards and cocked itself.

At this point I had no idea anything was wrong, so I tried another shot and it never fired properly again.

I have noticed 2 (possibly 3) issues:

1) The hammer appeared to be slightly off center. From my recollection it had always been like this. So far off the side that the inside of the hammer would rub the no 11 caps. I had a smith bend the hammer back sideways and it is now (better) centered.

2) The drum is ever so slightly bulged. I can not measure with a caliper as the bulge is parallel to the casting on the opposite side, but if I put a straight edge on it, I can see maybe .005" bulge.

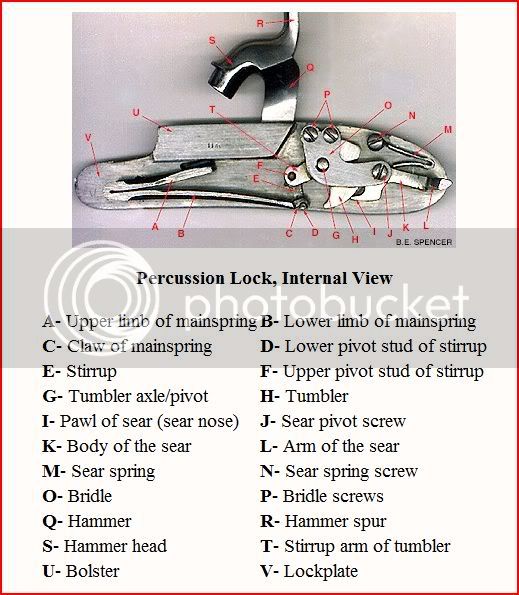

3) Not sure how to measure the main spring strength, but I may have messed it up when it "backfired" the cock. I read somewhere on the internet that if you can hear the main spring "click" when cauking the gun, it may be on it's way out. When I dissasemble the lock, removing the fly and all, I can still hear the spring "click" when cocking. If someone can tell me where to get a new one, I would love to try and change it out.

The rifle is very clean and always has been. I have taken the lock off and lightly oiled the little bits here and there.

I can not install a Four Winged Musket Cap Nipple as the casting sits a bit higher around the milled "flat" around the nipple hole. The only alternative is to possibly grind it down until I can get it to seat properly.

This is my main question: Can I use Four Winged Musket Caps with my No 11 nipple???

I have (empty) fired 10 caps in a row and it works great. Is this dangerous? Can it cause inconsistent accuracy? What's the worse thing that can happen?

Happy thanksgiving to all in the US!

-Alex in Toronto

I have had a consistent problem ever since I inherited my father's Hawkin replica.

I think I caused the problem. When I first took the gun out, I shot 10 shots in a row, without cleaning between shots. On the next shot, something (bad) happened and the hammer was shot backwards and cocked itself.

At this point I had no idea anything was wrong, so I tried another shot and it never fired properly again.

I have noticed 2 (possibly 3) issues:

1) The hammer appeared to be slightly off center. From my recollection it had always been like this. So far off the side that the inside of the hammer would rub the no 11 caps. I had a smith bend the hammer back sideways and it is now (better) centered.

2) The drum is ever so slightly bulged. I can not measure with a caliper as the bulge is parallel to the casting on the opposite side, but if I put a straight edge on it, I can see maybe .005" bulge.

3) Not sure how to measure the main spring strength, but I may have messed it up when it "backfired" the cock. I read somewhere on the internet that if you can hear the main spring "click" when cauking the gun, it may be on it's way out. When I dissasemble the lock, removing the fly and all, I can still hear the spring "click" when cocking. If someone can tell me where to get a new one, I would love to try and change it out.

The rifle is very clean and always has been. I have taken the lock off and lightly oiled the little bits here and there.

I can not install a Four Winged Musket Cap Nipple as the casting sits a bit higher around the milled "flat" around the nipple hole. The only alternative is to possibly grind it down until I can get it to seat properly.

This is my main question: Can I use Four Winged Musket Caps with my No 11 nipple???

I have (empty) fired 10 caps in a row and it works great. Is this dangerous? Can it cause inconsistent accuracy? What's the worse thing that can happen?

Happy thanksgiving to all in the US!

-Alex in Toronto