Very interesting how it is done. I am pretty sure that Maria will always remember these moments.

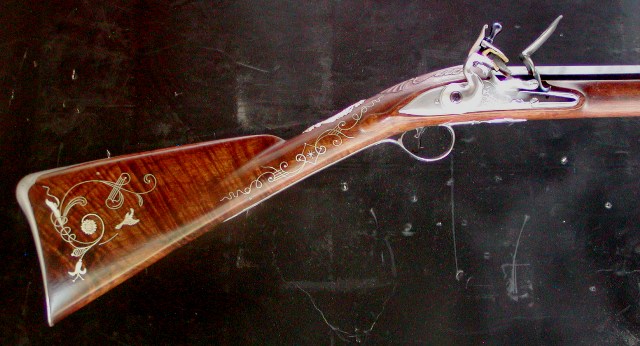

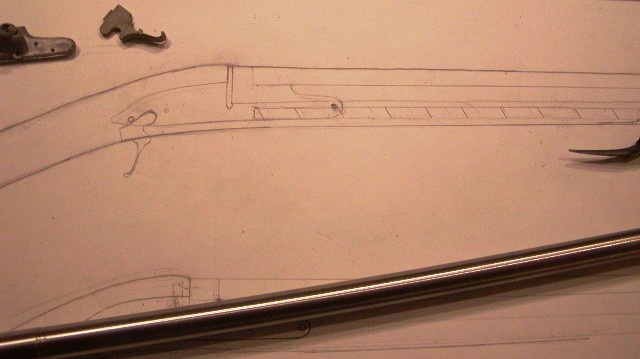

Will the long butt plate return get a tang to pin it to the stock?

Will the long butt plate return get a tang to pin it to the stock?

Very interesting how it is done. I am pretty sure that Maria will always remember these moments.

Will the long butt plate return get a tang to pin it to the stock?

Plenty of top female surgeons , dentists , veterinarians , mechanics etc out there why not gun makers ?….women with tools…

Yep, my wife was a CNC machinist for twenty years. She shoots bows and guns better than I do too!!!Plenty of top female surgeons , dentists , veterinarians , mechanics etc out there why not gun makers ?

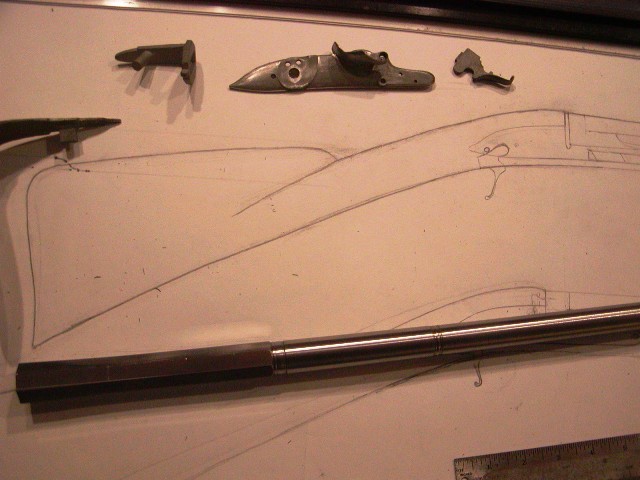

"Maria cleaning up the welds with the Dremel destroyer."

Got a big kick out of that. Once she masters that, she can begin on the Dumore Godzilla Grinder or "Hand Held Milling Machine" with 0-5/32" Adjustable Chuck.

I have good results with a Dremel tool doing my lock mortises. (Being able to actually control the bit is the key) but that’s it’s only use with a gun stock for me.

View attachment 184662

Gus

Fortunately Dave does "long distance" mentoring for us all. I know all of us understand the kind of time and effort it takes to document these builds as Dave does and we all greatly appreciate it!Great thread Dave. I'm thrilled and jealous of having such a mentor as you.

Merry Christmas to y'all!

We love bashing stuff.

My kind of shop! I'll be over with my kit soon. Hope your shop is insured!We love burning and melting stuff.

Enter your email address to join: