My next project is to completely rebuild my old Pedersoli Frontier. This is just going to be a "no pressure" fun rebuild that will hopefully result in a nice looking rifle when done, though not of any particular school. My real goal is to end up with a nice lightweight flintlock for my wife.

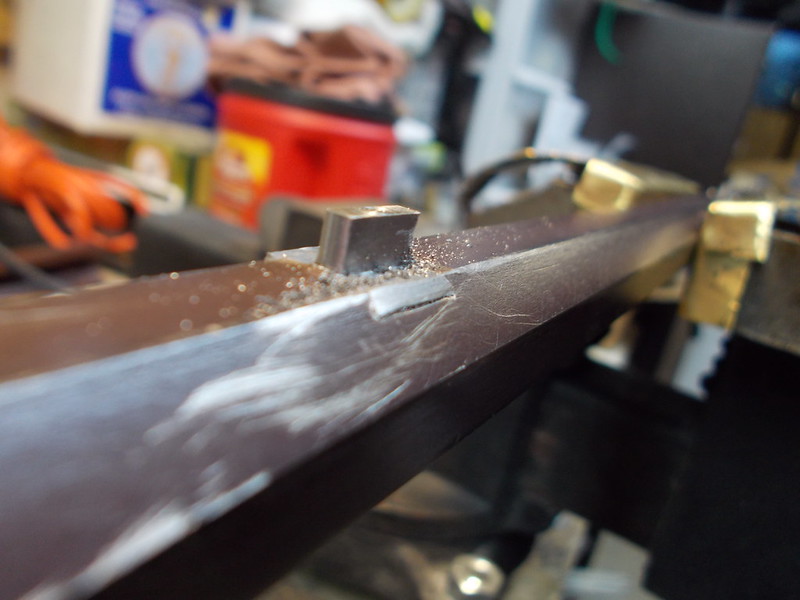

The base I started with was a .36 caliber percussion. I've already had Bobby Hoyt rebore the 13/16" barrel to 45 caliber with 1-56 twist round bottom grooves. He also cut off the patent breech since the drum hole was so low it had exposed threads into the next flat. :shocked2: So that took the 39' barrel down to 38".

I've started another Flickr Album to document the process. I've already done the breech plug fitting (was supposed to be done when the barrel came back to me but wasn't, so forced me to learn something new :grin: ).

Since this is being converted from percussion to flint and the drop in options from Pedersoli and L&R were "bad" and "worse," I'm using a quality Chambers builders lock. I've started the process of working that to fit the existing mortice.

When done, this will not be recognizable as the old Frontier! If you have an interest, feel free to follow along. As with my Flint Hawken album, if you double click on a picture, it will enlarge the size and allow you to see the build notes I am making under the pic.

https://www.flickr.com/photos/100435142@N08/sets/72157650877821348

The base I started with was a .36 caliber percussion. I've already had Bobby Hoyt rebore the 13/16" barrel to 45 caliber with 1-56 twist round bottom grooves. He also cut off the patent breech since the drum hole was so low it had exposed threads into the next flat. :shocked2: So that took the 39' barrel down to 38".

I've started another Flickr Album to document the process. I've already done the breech plug fitting (was supposed to be done when the barrel came back to me but wasn't, so forced me to learn something new :grin: ).

Since this is being converted from percussion to flint and the drop in options from Pedersoli and L&R were "bad" and "worse," I'm using a quality Chambers builders lock. I've started the process of working that to fit the existing mortice.

When done, this will not be recognizable as the old Frontier! If you have an interest, feel free to follow along. As with my Flint Hawken album, if you double click on a picture, it will enlarge the size and allow you to see the build notes I am making under the pic.

https://www.flickr.com/photos/100435142@N08/sets/72157650877821348

Last edited by a moderator: