Andrey22

Pilgrim

- Joined

- Aug 31, 2012

- Messages

- 162

- Reaction score

- 215

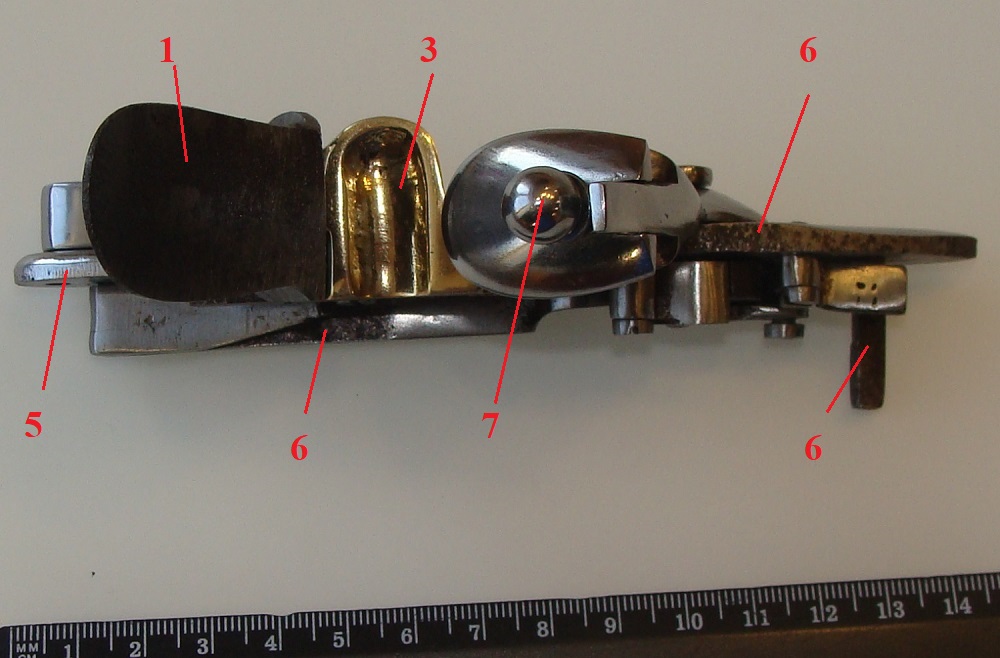

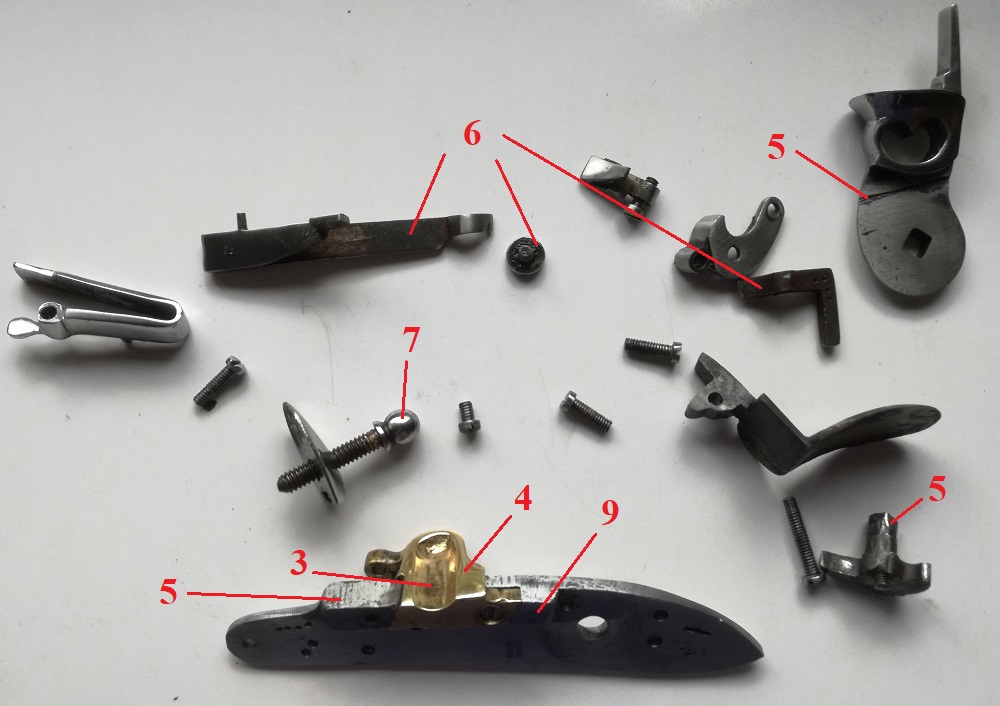

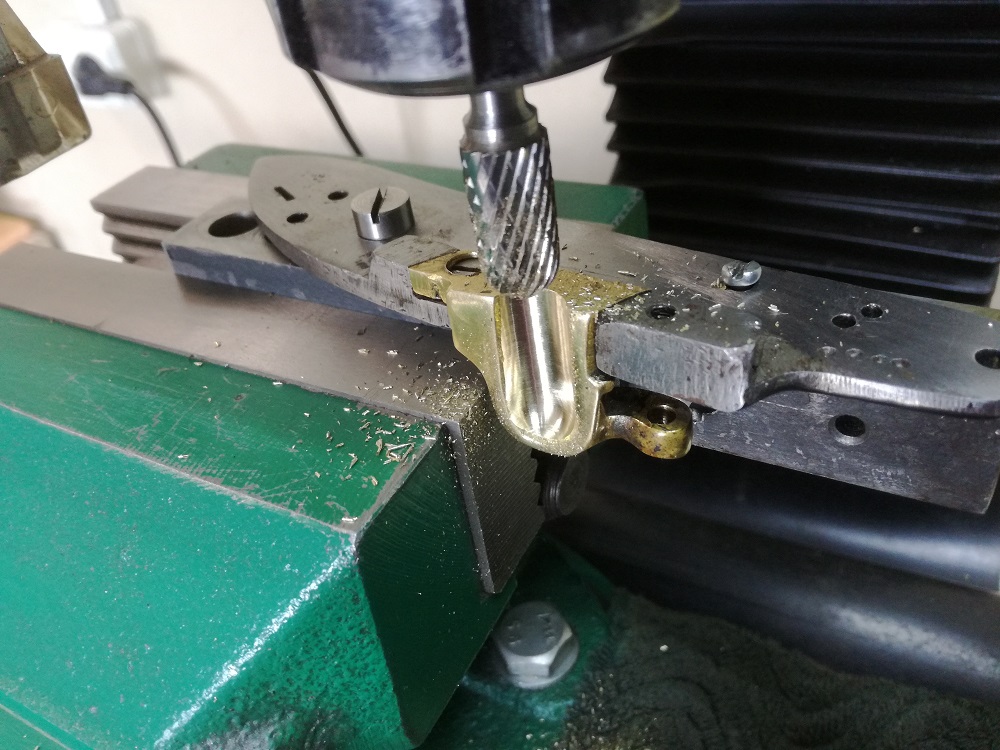

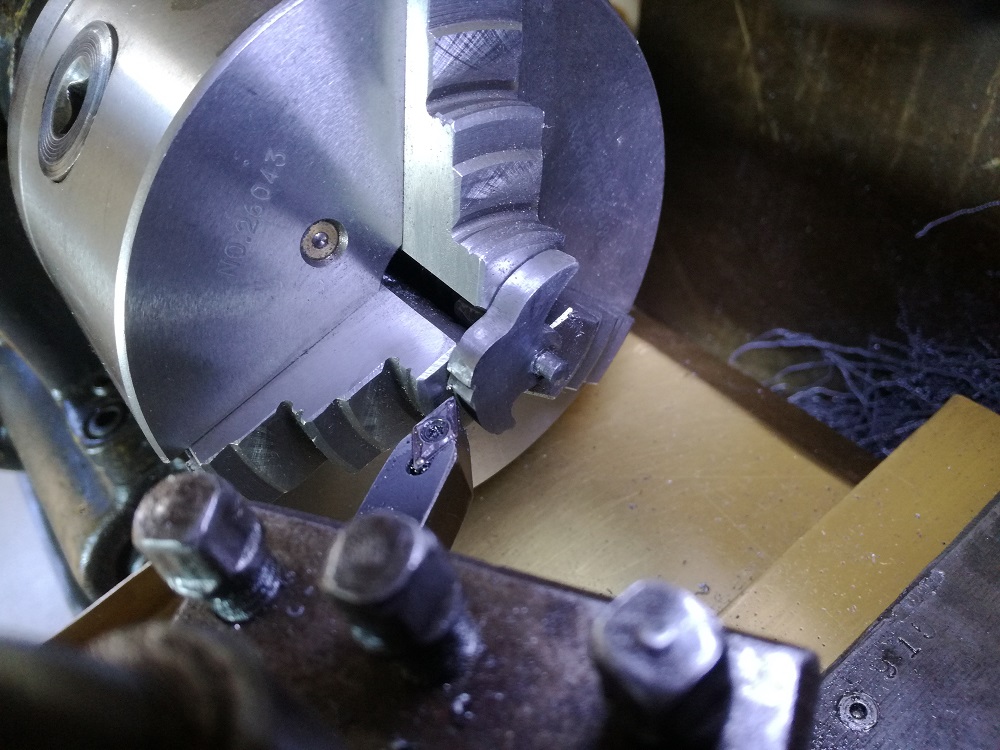

I have tried several times to buy flintlocks in India. They looked good in the photos on the seller's website and their price is only $90. Within 5 years I have bought 3 different castles. And each time their quality was terrible. Negotiations with the seller were unsuccessful. I want to show one of these locks and how I renovated it.